Intuitive Design Method (IDM), A New Approach on Design Methods Integration

Editor | On 04, Oct 2000

Denis CAVALLUCCI

denis.cavallucci@ensais.u-strasbg.fr

Laboratoire de Recherche en Productique de Strasbourg

24, Boulevard de la Victoire

67084 STRASBOURG CEDEX

FRANCE

Philippe LUTZ

phillippe.lutz@ensais.u-strasbg.fr

Laboratoire de Recherche en Productique de Strasbourg

24, Boulevard de la Victoire

67084 STRASBOURG CEDEX

FRANCE

ABSTRACT

When facing today’s world competition, the concept of “fastinnovation†that allies both innovation and time to market, is a surviving matter. In the science of new product design, many different approaches have been formalized, but most of this scientific work has been performed at academic level. In this paper we discuss about a new approach to use these design methods in order to build an “Intuitive Design Methodâ€(IDM), based on previous knowledge and technological background of the company. Based on these acknowledgements a flow chart of Intuitive Design Method building will be presented. Then, a case study will support our approach. This case study has been conducted in M.G.I. Coutier one of the French automotive supplier leader and the presented product will be an intake manifold. Both these theoretical and practical approaches will lead us to a conclusion that demonstrate the usefulness of the IDM model, and that there is no metamethod that can be apply to any company, but a dynamic set of existing basic rules. These rules have to be formalized in order to significantly increase engineers abilities to conduct and to optimize a total design process.

1 INTRODUCTION

Companies have ever been confronted with the question of development. In the face of competition, the ever more rapid emergence of new products, changing consumer fashions and globalisation, they are forced to call into question the efficiency of their design methods to keep their competitive edge and ensure their survival. Within this very general frame, work on design methods has always tended to foster one or other dimension of the process, which isolates the notion of need from the industrialized product.

Moreover, in almost all books and international publications presenting the most advanced work on design, key references are credited to the 3 major economic and industrial centers, i.e. the USA, Japan and Europe. And yet, geographically speaking, the scope of knowledge on Earth is not limited to these 3 major centers. Fundamental importance must logically be awarded to the former Soviet Union in fields belonging to the so-called pure sciences (mathematics, physics, chemistry etc.).

During our research, we have had contacts with some of these countries on several occasions (Russia, Belarus, Ukraine, Azerbaijan and Moldavia etc.) and the foundation for our research paradoxically stems from our discovery that some areas of industrial knowledge had experienced developments in the former Soviet Union of which we were completely ignorant. We also realized that they were going to help provide us with answers.

An acceptable model of the design process, based on an analysis of several contacts with the academic and industrial world, must meet a large number of requirements [Nordlund (1996)] . To establish this type of model, a survey of existing design methods was conducted.

Choices concerning the selection made for the rest of this thesis result from an analysis of what exists in the industrial and academic fields on the subject of design. The convergence of these two worlds sometimes gives common standpoints on certain methods which have been deemed relevant and are used for their capacity for meeting the designer’s needs.

2 SUMMARY OF THE DESIGN METHODS

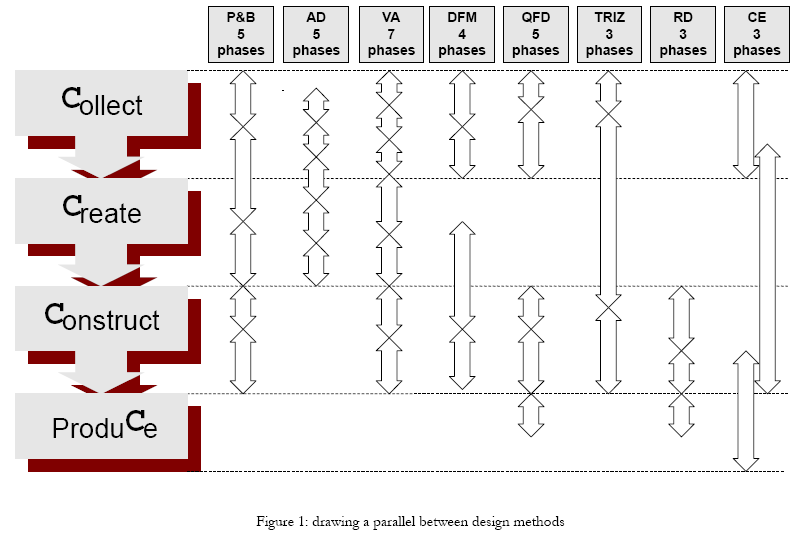

The methods analyzed are Value Analysis (VA), QFD, Axiomatic Design (AD), the Pahl & Beitz approach (PB), Concurrent Engineering (CE), Robust Design (RD), Design for Manufacturing (DFM) and the TRIZ method. After analyzing the various design methods, our initial reaction was that confusion reigns as to what they can offer the designer. Indeed, while they all advocate that they can act as a reference in terms of how a design project should be conducted, they rarely make allusions to what could be perceived as complementarity between them. This state of affairs often leads to redundancy in terms of the answers they provide for the designer.

If we adopt an abstract dimension for the methods studied, the various representations of the development process provide us with a common vision centered on 4 essential phases1: data collection and analysis (Collect); creation (Create); construction (Construct); and growth (ProduCe).

3 CONTRIBUTING TO INCREASING EFFICIENCY IN THE DESIGN ACTIVITY: IDM

The four phases clearly pinpoint the essential notions for all the methods in our study. Since they are highly generic, they provide a structural approach to the project and in no way consist of a rigid, fixed structure. This abstraction phase will enable us to put forward hypotheses as to the use of one or more “strong points” associated with a method and to link them up to one or more strong points in another.

We should remember that no method takes the methodological history of the company into account. Their structure is fixed in relation to this and any company that operates one method or another (or sometimes merely rules) is therefore obliged either to train themselves regarding the new method they wish to adopt, or to adapt it to what already exists in their company by acting intuitively in terms of its integration. Backed by this statement of fact, our analysis is therefore based on a prior survey of what exists on a methodological level.

This survey is then used in a logical fashion to build up the integration strategy best suited to the company. Our conclusion is that ideally, the designer should be able to increase the relevance of his project with a minimum number of changes to his design habits. In order to do this, we offer to draw up a survey of the strong points of each method with the aim of detecting any deficiencies in terms of relevance in the project and to bridge these deficiencies, not by integrating a method wholesale, but by integrating its strong points alone.

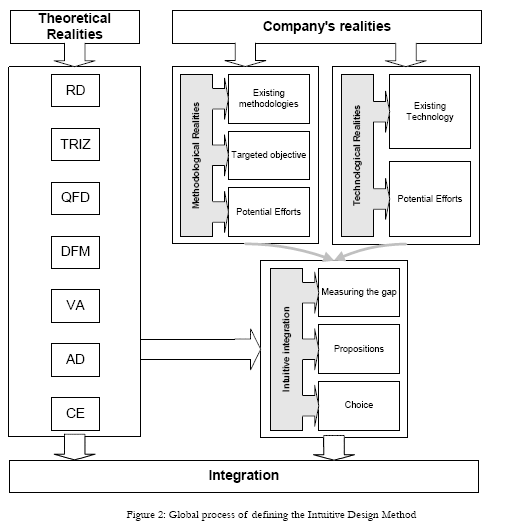

Once the state of the art of the strong points in design methods has been formalized and since the methodological and technical knowledge of the company is a known factor, it becomes possible to deduce which intuitive design method may be most appropriate for a given company.

When following this procedure, it would seem essential to draw up a document to process the company’s data. Furthermore, this document must be designed so that it can be drawn up rapidly and it must be easy to use. The findings of this type of analysis should provide the final choice of strong points in each method for each stage of the project.

Time being an important factor for companies with regard to this type of analysis, we believe it is important to underline the company’s skill-building efforts at each stage of the project so that this can be recorded in the document, if necessary.

3.1 TRIZ’S CONTRIBUTION TO THE SCIENCE OF DESIGN [SOUCHKOV (1998)]

In the light of the comparative analysis we have conducted, the method appears to be atypical in terms of its contribution to design methods. Indeed, its relevance and operational profile are fundamentally different from those of other methods studied. This is particularly true for the creativity phase which, although its is barely relevant in other methods, is the strong point of TRIZ, since the methodological effort of a company wishing to improve its design process will no doubt occur with TRIZ.

4 INTEGRATION METHOD

4.1 DIFFICULTIES IN APPLYING TRADITIONAL METHODS

In the introduction to this section, we will give a brief summary of the difficulties linked with applying the design methods quoted in the previous section. The term “difficulty” encompasses in particular:

• Learning difficulties: this arises from the fact that the methods have often been developed in research laboratories and are still not widespread in companies. The fact that training programs for some of them are virtually nonexistent in engineering courses adds to the fact that the learning process presents a difficulty for the industrialist.

• Difficulties linked with doubts surrounding the profitability of the investment. The financial aspect obviously presents a difficulty and a major obstacle to the integration of the new method. The economic context merely accentuates this difficulty since it is not easy, on first contact with a new method, to grasp the return on investment in man-hours that it will generate. The training/counseling aspect is added to the cost as soon as it becomes apparent that the company lacks skill with regard to the method.

4.2 MEASURING THE GAP

Our analysis of the various design methods has revealed a certain amount of complementarity, which has sometimes led to research work [Malmqvist (1996)] [Schulz (1999)] . It would seem logical that the ideal combination would consist in collecting and analyzing data with QFD, generating concepts with TRIZ and ensuring the optimization of parameters with Robust Design [Verduyn (1995)] . Yet this combination is only ideal from a theoretical point of view. A whole panoply of difficulties awaits designers who wish to combine these methods.

• Difficulties in skill-building for a set of methods which are not mastered.

• Difficulties in combining methods in the same project or the need to create interfaces between them.

• The time-span of the project is increased significantly due to the inertia inherent in applying three methods. Our conclusion is that ideally, the designer should be able to increase the relevance of his project with a minimum number of changes to his design habits. In order to do this, we offer to draw up a survey of the strong points of each method with the aim of detecting any deficiencies in terms of relevance in the project and to bridge these deficiencies, not by integrating a method wholesale, but by integrating its strong points alone.

4.3 HIGHLIGHTING THE STRONG POINTS OF DESIGN METHODS

The classification of strong points for each design method has been formalized and deliberately restricted to four since, beyond this number, it becomes difficult to identify the real advantage of the point in question. The object of this formalization is to offer the company a strategic choice in its decisions regarding the orientation of its design method. The stages and generation of the intuitive design method

Since the state of the art of the strong points in design methods has been formalized and the methodological and technical knowledge of the company is a known factor, it is now possible, according to the following graph (figure 2) to deduce which intuitive design method may be the most appropriate for a given company.

5 IMPROVEMENT IN THE PERFORMANCE OF THE DESIGN ACTIVITY AT MGI COUTIER

An industrial application has been developed within the frame of this research activity. It was conducted at the company MGI Coutier (an automobile parts manufacturer). The project selected as the presentation medium was the intake manifold.

The intake manifold is an important element in the gas inlet zone of the cylinders. Its shape and the lack of space available under the bonnet mean that today, it is an element which has undergone little optimization in terms of its structure and shape. With the aim of improving its performance in use, the intuitive design method developed in our research project has been major problem related to its shape.

5.1 INCREASING DESIGN EFFICIENCY

The MGI design method

As with several of the companies we contacted, MGI have their own design method. Based on the current know-how of the engineers and past experience in applying different methods with varying degrees of success, MGI uses an “integrative and associative” procedure with regard to the 4 phases in the following form:

The specificity of design activity at MGI lies in the fact that upstream research and computation are centralized at a research center located in the Bas-Rhin in France. This research center employs some 40 engineers and 20 technicians and is in charge of research on new products and systems. The notion of novelty lies in the aptitude of development centers to conduct a study independent of the research center (re-looking, minor developments etc.). Upstream studies requiring the backing of research (materials, process, technology, innovation etc.) are initially dealt with by the research center before being transferred to development and industrialization in the various development centers. It should be noted that development centers may deal with a study independently while, in terms of resources, calling solely on the computational center (simulations, flow, analyses etc.).

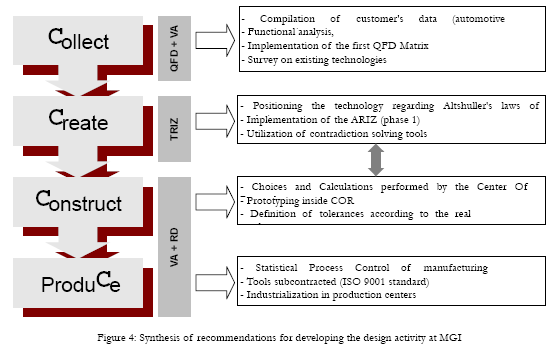

Analysis of the efficiency of the design activity Using items returned by customers and personal analyses as our basis, we were able to compile data on the aptitude of MGI’s project teams to overcome the obstacles inherent in the 4 phases. We noted that the collecting phase is heavily invested by QFD [Hauser (1988)] due to the fact that one of MGI’s sizeable contractors impose skill-building on them for this tool, underlining the importance of mastering this method. Synthesis and recommendations for skill-building in MGI’s design activity

Figure 4 clearly demonstrates the importance of investment in training and expertise for the company, in particularly for the Collect and Create phases.

Details on the actions undertaken to increase efficiency in design Our assessment suggests that two key actions should therefore be undertaken:

• The first concerns the acquisition of the strong points in TRIZ (in particular with problem-solving tools). A training course lasting 5 days has therefore been set up to reach this target. We have also suggested to MGI that one person should be selected from the trained group to become the “inhouse” specialist who will be the resource person for future applications.

• The second aims to improve appropriateness in terms of industrialization (in particular for plastic parts), the real specifications required by the customers and the technological capacity of the production tool [Taguchi (1987)] . In this framework, some notions of robust design are put forward in a second training course lasting 5 days.

This second point is nonetheless more complex to grasp since the development units which need to be associated with the process are numerous and therefore investment is high.

We will nonetheless put it to MGI that a specialist in Robust Design should be trained in an attempt to transfer part of the knowledge acquired to future actors in the design phase.

5.2 APPLICATION FOR A PRACTICAL CASE: THE INTAKE MANIFOLD

Generating an application method for developing concepts From the strong points which have arisen from the design methods, we were able to build an intuitive design method adapted to MGI’s industrial reality. Initially, the different phases were formalized. The aim was to apply all the tools best adapted to the project. The problem posed presented a need for largescale development. Particular effort will therefore be focused on the phases upstream to the design stage so that the utmost may be done to ensure that the ensuing concepts are innovative. The drawback here is that the ensuing concepts will probably require research in the medium term. Figure 5 gives a summary of these steps and the expected objectives.

Findings of the computational study

The study on the manifold called “4-in-1divider” demonstrates that in order to obtain optimum engine fill, the length of the pipes must be varied. If the volume of the plenum chamber is altered, the results are low and may even be slightly negative. A variation in the diameter of the pipe inlet is harmful if it results in the pipe having a “divergent-convergent” shape. This analysis demonstrates the full relevance of correlation between the creation phase and the construction phase. The iterations required between these two phases lead us to state that the proximity of the design and computational centers and the multidiscipline approach of the different actors in the design phases largely contribute to the notion of total design.

This study, undertaken using Wave software, allowed us to assess the effects of variations in the dimension on the traditional divider, and then on the new concept of the “4-in-1” divider. We were therefore able to see that this new concept could help develop a divider where the length of the pipes is easily adjustable. Furthermore, another advantage in this divider is that the swirl effect is fully utilized inside the plenum chamber, if the distribution of the pipes is correctly arranged. Wave was unable to modelize this phenomenon (code 1D). Simulation using Fluent (fluid mechanics code) in non-stationary 3D should enable this idea to be validated.

Synthesis on the upstream design study

To summarize this upstream study on concept research, the following points have been deciding factors in the reformulation of the problem:

• Highlighting the utility of applying ARIZ [Altshuller (1986)] when no obvious contradiction arises.

• The absolute need to project the system in the radar diagram of the law of evolution. This enabled us, in particular:

* To demonstrate the limits of the system’s operation due to its non-symmetry;

* To demonstrate in which direction concept research should progress: the dynamics of the manifold.

• Finally, the principles of separating physical contradictions [Altshuller (1989)] constitute the most appropriate tools in our situation.

To conclude, the necessary complementarily between the specialist in the technical field under study and the TRIZ specialist who plays a “facilitating” role at key moments in the project has once more been highlighted in this case.

6 CONCLUSIONS

Fundamental sciences are too often ignored in design. This is probably due to the fact that courses in engineering schools for industrial sectors have little room for physics and chemistry etc. The result is that company engineers turn away from these resources and adopt design routines which revolve around the knowledge acquired in their specific discipline alone. Reducing mechanical systems to simple principles of physics can, however, contribute significantly to the development of the design activity [Souchkov (1996)] .

Creativity too is often left by the wayside when companies make choices in terms of investments to increase their competence in design. The image of creativity as innate knowledge is still present in people’s minds and our findings have often led us to make the following statement: in order to build up competence in the design activity of R&D departments, we believe that the key to success lies in moving on from a logic of innate creativity to a logic of systematized creativity [Altshuller (1988)] .

The metamethod, so sought after in research, probably does not exist. Therefore we believe that setting up an intuitive design method which strays as little as possible from the company’s current method, is the right path to follow. The effort to build up competence thus defined must not only have a bearing on the deficiencies detected in the company. This detection work must be independent from any sectorial polarity since reality is often interpreted differently by each of the actors involved. The purpose behind this dynamic method is to increase the efficiency of design in a given company, and a fresh application will be required for each new company.

7 ACKNOWLEDGMENTS

In this section we would like to thank both the Alsace Region for supporting our research work on TRIZ and its integration with occidental design science and MGI Coutier Company for allowing us to use and publish part of the study we have led with them.

This paper is partly a synthesis of the author’s thesis, entitled “Contribution to new mechanical system design using methodological integrationâ€. The presentation of this thesis has been held in ENSAIS, Strasbourg (France) December 14th 1999.

8 REFERENCES

[1] Altshuller G.S. To Find an Idea: Introduction into the Theory of Inventive Problem Solving, Nauka, Novosibirsk (in Russian), 1986.

[2] Altshuller G.S. Creativity As An Exact Science, , Gordon & Breach, New York, USA, 1988, ISBN 0-677-21230-5

[3] Altshuller G.S., B.L. Zlotin, A.V. Sussman & V.1. Filatov, Search for new ideas: From Insight to Technology (Theory and Practice of Inventive Problem Solving), Karte Moldaveniaske, Kishinev (in Russian), 1989.

[4] Cavallucci, D. Lutz, P. “Beyond TRIZ Limits†The TRIZ Journal, March, 1998.

[5] Cavallucci, D. Lutz, P., TRIZ, Une nouvelle approche de résolution des problèmes d’innovation, International Journal of Innovation Research. N°1 Vol.1 1999.

[6] Hauser, J. R. , Clausing D., “The House of Quality,” The Harvard Business Review, May-June, No. 3, pp. 63-73, 1988.

[7] Malmqvist J., Axelsson R., Johansson M., “A comparative analysis of the theory of inventive problem solving and the systematic approach of Pahl and Beitzâ€, ASME Design Engineering Technical Conference, August 18-22, Irvine, California, 1996.

[8] Miles, L. D., Techniques of Value Analysis and Engineering, McGraw-Hill Book Company, New York, NY, 1961.

[9] Nordlund M., “An Information Framework for Engineering Design based on Axiomatic Designâ€, Doctoral Thesis, Department of Manufacturing Systems, The Royal Institute of Technology (KTH), Stockholm, Sweden, 1996. ISRN KTH/TSM/R-96/11-SE

[10] Pahl, G. and Beitz, W., Engineering design, London: Design Council, 1984.

[11] Schulz A., Clausing D., Negele H., Fricke E., “Shifting the view in systems development – Technology Development at the fuzzy front end as a key to successâ€, Proceedings of 1999 ASME DETC, 11th International Conference on Design Theory and Methodology, Las Vegas, September 12th –15th, 1999.

[12] Sohlenius G., “Concurrent Engineering” Annals of the CIRP, Vol. 41, No. 2 pp. 645-655, 1992.

[13] Suh N.P., The Principles of Design, New York: Oxford University Press, 1990. ISBN 0-19-504345-6

[14] Taguchi, G. System of Experimental Design: Engineering Methods to Optimize Quality and Minimize Costs, Vols. 1 & 2, UNIPUB/Kraus International Publications, White Plains NY., 1987.

[15] Souchkov V., “TRIZ and Technosocial Competition.” The TRIZ Journal, February, 1997.

[16] Souchkov V., Alberts L., Mars N., “Innovative Engineering Design Based on Sharable Physical Knowledgeâ€, Artificial Intelligence in Design’96, J.S. Gero and F. Sudweeks, eds., Kluwer Academic Publishers, pp. 723-742, 1996.

[17] Souchkov V., Mars N., “Knoweledge-Based Support For Innovative Designâ€, PhD Thesis, University of Twente, The Netherlands, 1998.

[18] Verduyn D. & A. Wu, “Integration of QFD, TRIZ, & Robust Design: Overview & Mountain Bike Case Studyâ€, Proceedings ASI Total Product Development Symposium, November 1-3, Dearborn, MI, USA, 1995.