Innovation Process As A Key To The Market Success In The Engine Manufacturing Business

Editor | On 03, Jan 2004

ABSTRACT

In the coming years, the aircraft industry is faced not only with a rising traffic volume together with an adjustment to large market fluctuations, but also to an increasing demand for environmental protection and more aggressive cost pressure. In order to meet these challenges, new technologies and business process are necessary. A focused innovation process, which does not allow the technology development to coincidence, must therefore be the goal. The innovation process of MTU covers the phases: determination of the customer requirements, systematic idea creation, selection of the correct innovations, focused development of the technologies, and finally securing the transfer of the technologies into the product. Presented will be the MTU innovation process together with the tools as well as substantial results.

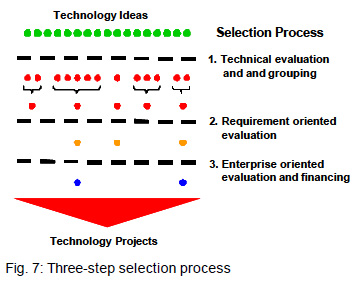

At the beginning of the innovation process from MTU are the customer technological requirements for the product and processes. Many of these technological requirements are already satisfied within the company through existing innovations. However, in many places new ideas must be developed. For that, TRIZ with a tool box of creative methods support the creation of innovative ideas and concepts. In a 3-step selection process, which is divided in technical, product/process and enterprise orientation, the ideas/suggestions that bring the highest customer satisfaction are selected.

The development of the technologies is finally controlled via a gating process. During a technology gate an evaluation of development maturity, risks, market, budget and resources occurs. The technology gating is closely interlocked with the gating process of the associated products, so that a transfer of the technologies into the product is guaranteed

1. Introduction

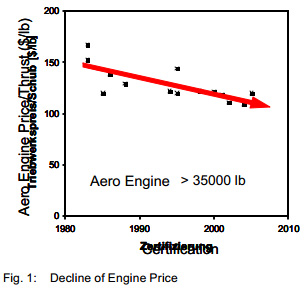

For an airline, which stands in front of a purchase decision of a new aero engine, is naturally the cost effectiveness of the product the focus. The critical parameters are the depreciation and/or interests and with that the production costs and development costs as well as the maintenance-cost and the fuel consumption. For the life cycle costs, the airline demands a reduction until 2010 of 20% to 30%. Fig. 1 shows the decline of the engine prices in the large aero engines.

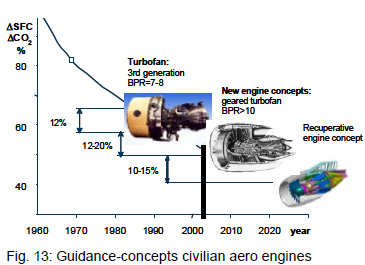

In the fuel consumption and with that the CO2- Emissionen, impressive improvements were achieved in the past years (Fig. 2). However, the requirements for 2010 are an additional reduction of 10% (Fig. 3).

Beside the costs and fuel consumption, the reliability of an aero engine was increased in the past 40 years by a factor of 10. Because of the increasing air traffic, the aero engine shut-down rate has to be cut in half until 2010. Altogether the aero engine manufacturers must prepare themselves to intensified market conditions and customer demands. All these requirements from airlines and governments until 2010 cannot only be achieved through improvements of the aero engine components. New aero engine concepts need to be developed to complete achieve all these challenges together with new development and manufacturing processes.

2. The MTU Technology Process

2.1. Objectives

In order to guarantee a requirement-oriented selection and development of the technologies, MTU develop in the ast two years its new technology process. For the selection of the right technology projects and the controlling of the technology development MTU wants:

· simple, traceable and effective process

· maximum competence in the evaluation process

· minimum expense for forming an opinion and making

a decision

· no parallel actions.

Goal of the MTU technology process is to orient the

technology projects and development to:

· fulfill the requests and expectations of the customers,

· use the technological and commercial opportunities,

· strengthen the innovation,

· introduce the highest possible portion of the developed

technologies into the product and/or process, and

· introduce the innovations quickly into the produc

2.2. Phases and teams

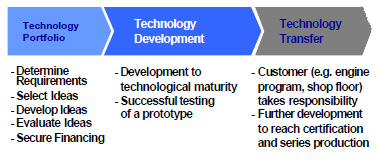

The technology process can be roughly divided into 3 phases:

· technology portfolio,

· technology development, and

· technology transfer (Fig. 4).

The tasks for the technical oriented stage are the supply of problem solutions to the technology requirement, the technical assessment of the suggested solution/idea, and the development of innovative ideas outside of the defined requirement. These tasks are handled through technology technical-specialist-teams.

The identification of the technology requirements together with the evaluation of the proposed solution concept are task of the technology product/process teams. These teams consist of representatives of the aero engine programs (customers of the technology).

The enterprise oriented view is brought into the process through the technology executive-committee, which consists of members of the MTU’s board of executives. It specifies the technology budget, decides on the execution of the technology projects and is responsible for technology strategy.

2.3. Technology requirements, Innovations and technology project selection Starting point of the Technology Portfolio phase is the determination of the technology requirements of products and processes (Fig. 6).

The requirements of the current and future aero engine programs are collected through the responsible aero engine design teams. The product strategy determines the technological requirements of the aero engine in the future with the help of leading concepts. The responsible technology product/process teams collect and evaluate these technological requirements. The result is a list of key technological requirements with information about the goal to reach and time to be finished.

In the next step, the technology requirements with a high priority are assigned to the responsible technicalspecialist team. These teams are charged to deliver ideas/innovations for every requirement. Many of the technological requirements are already satisfied within the company through the existing ideas/innovations. However, in many places new ideas and concepts must be developed. For that, the technical-specialist teams start the process of developing ideas (innovations).

Usually these teams initiate innovation workshops and are supported thereby from internal and external creativity specialists. Most of the time TRIZ and a tool box of creative methods support the creation of innovative ideas and concepts. The advantage here is that the technology portfolio management maintains a technology pull principle.

The last step in the technology portfolio phase is the evaluation of the ideas/innovations which is done with a three-step selection process (Fig. 7).

1. Technical oriented evaluation and grouping The technical oriented evaluation is accomplished by the technical-specialist teams, which evaluate benefit, costs, dates and risks of the technology idea. Usually these ideas are only subtasks of a technology project. Also most of the time competing ideas to the same problem exist. The task of the technical-specialist team is also the definition of technology projects from the available technology suggestions.

2. Requirement oriented evaluation The technology projects are evaluated from the product/process teams concerning benefit and expenditure as well as the fit to the technology requirements. This evaluation goes into a recommendation to the executive-committee regarding the execution of selected projects.

3. Enterprise oriented evaluation and financing Finally, the technology executive-committee decides on the execution of the technology projects. It considers the financial situation and strategic criteria.

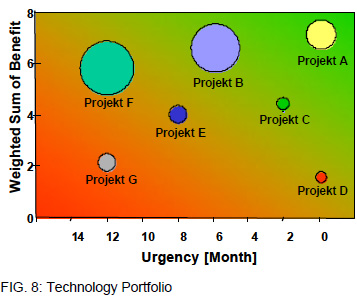

To obtain a better overview of all projects for the product and processes, a portfolio of all the technology projects is provided (Fig. 8). Each project is therefore examined, what contribution it supplies to product/process specific criteria. Such criteria for an aero engine compressor are function criteria such as efficiency, stability and reliability, cost criteria such as manufacture and development costs as well as market criteria such as competitive position and customer acceptance. These single criteria are evaluated and a weighted sum of benefits is plotted.

Also the urgency of the technology project is evaluated as the duration up to the latest starting date for the work on the project (Urgency = required date – duration of the project.)

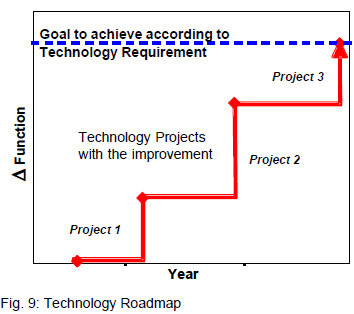

To determine the technological gaps for the technology requirement, the technology roadmaps (Fig. 9) are provided, which show the improvements by the individual technology projects and the goal values and required date of the associated engine program and/or process (technology customer).

2.4. Development of the technologies

The complete MTU technology process from technology portfolio through technology development until technology transfer is divided into 6 phases (Fig. 10).

The technology portfolio phase (initial and definition phase) was already presented above. It ends with a specification for the technology project. The actual development of the technologies can now take place.

This is divided into the following phases:

· Concept phase – different concepts are examined and evaluated.

· Design phase – selected concept is developed and a prototype is provided.

· Testing phase – technology is tested with

representative tests (test rig, demo software…) and the technology maturity is proven.

· Transfer phase – technology is handed over to the customers (e.g. engine program or shop floor) and developed further by the customer up to the manufacturing of series production parts and/or up to the productive process.

Delays or not reaching the technological goals during the development causes for the technology customer usually expensive new changes re-machining or payments. In order to minimize this risk, a gating process is established to examine the technology development. Before the next phase in de technology development can start, a technology gate needs to be passed first (Fig. 10).

Before each gate a technical-specialist team performs a technical review. Within this review the technical development maturity is examined.

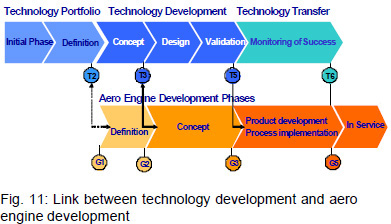

Crucial for the success of a technology development is the transfer of the technologies into the products. Therefore, within the technology gating the customers of the technology as well as the required dates and budgets are examined. During the beginning of the technology portfolio phase a rough statement from the customer is sufficient. However, during the technology development phase of the technology a confirmation of the later customer for the planned employment must be present (Fig 11.)

Apart from the methods already mentioned further aids are available for an effective work in the technology process (Fig. 12).

Particularly to mention are:

· TRIZ which is used from the technical-specialist teams to help fulfill the technological requirements with ideas.

· IP3E – integrated product development, production and preservation. IP3E regulates the project oriented integrated teamwork of all relevant specialist areas as well as interaction between line and project.

· Standard Work. In standard work all operational sequences/processes for development, production and preservation are document. It guarantees that the necessary inputs for the subsequent work are available.

· Design Make Build Guide. In Design Make Build Guide all the MTU existing knowledge is documented. It is the obligatory technical basis for the tasks within standard Work performed through the IP3E teams.

· IPM – Through Intellectual Property Management the know-how is secured against third parties (patents).

3. Results

3.1. Leading-Concepts

The technological requirements of future aero engines are defined through leading concepts. These concepts have a detailed description of the necessary technologies.

MTU defined leading concepts with different time horizon.These leading concepts characterize in each case a newgeneration of aero engines (Fig 13.)

With these leading concepts MTU covers the mid- and long-term developments. With all concepts national and international co-operation is used.

3.2. Compressor Technology

The most challenging component in an aero engine is the high pressure compressor. Based on the MTU experiences for military high pressure compressor, research and development of fundamental technologies together with rig test were initiated to expand into the civilian applications.

Since the compressor development is connected with large risks, all new technologies are extensively tested in a close-to-reality compressor test. Fig. 14 shows the rotor of a high pressure compressor, which has a pressure ratio of 11 in only 6 stages due to progressive compressor technologies. The small amount of stages reduces clearly the manufacture and maintenance costs. Furthermore, the compressor received two awards: from Aviation Week & Space Technology the Aerospace Laurel Award 2002 and the Innovation Award of German industry 2003.

This technology compressor supplied extremely convincing results concerning efficiency and stability. In June 2002 the HDV12 was selected finally as high pressure compressor for the PW6000 engine, the power plant for the airbus A318, Fig 15. The HDV12 is a successful example of the technology transfer from fundamental technologies into the product.

3.3. Intelligent Aero Engine

Progress within electronics, sensors and electric drives opens new possibilities, which lead to intelligent control

for additional degrees of freedom in “Smart Compressor Design†such as active surge control, active vibration

control or active clearance control (FIG. 16).

3.4. Experience with TRIZ

Since the technology portfolio management maintains a technology pull principle, the technical-specialist teams are charged to deliver ideas/innovations for every technological requirement. For the case that new ideas and concepts need to be developed, the technicalspecialist teams use TRIZ to support the creation of innovative ideas and concepts. The advantages are:

· faster and effective method to generate innovations,

· toolbox of different methods for the different problems,

· reduction of development risks and costs,

· evaluation of future trends of technologies, and

· generation of ideas in situations where practically all ways are blocked through patents from the competition.

3.5. Conclusion

MTU started a technology process about 10 years ago. The presented approach became active about 2 years ago. Successes of the new technology process are recognizable from the fast introduction of numerous technologies to new products. The new technology process led to an increased creation of value and a strengthened position at the world market. Specifically MTU‘s success in innovation is based on:

· a well structured process to identify customer’s requirement

· TRIZ with a tool box of methods to generate and evaluate innovative ideas

· a three-step process to generate the technology portfolio

· Gate process to ensure development with permanent customer focus

For the success of the technology process the commitment of the organization by involvement of technical experts, program managers and top management was curtail. This was achieved through a high transparency of the decisions and merging all relevant forces in the MTU.