TRIZ And Machine Maintenance Case Study - Part 2 – Managing Constraints And Perceptions

Editor | On 26, Oct 2003

Director

CREAX nv, Ieper, Belgium

darrell.mann@creax.com

John Cooney

Academic Researcher

School of Business and Government

National University of Ireland, Cork

j.cooney@ucc.ie

Barry Winkless

CREAX, Ireland

bwinkless@eircom.net

Abstract

This article follows on from a first paper examining the application of TRIZ to the improvement of the performance and maintenance of a yogurt bottling plant. In this part, we examine how a novel perception mapping tool was used in conjunction with TRIZ to examine and handle the constraints and human issues associated with the problem. As is often the case, the constraints dictated by these people issues can very easily come to dominate a problem setting. Traditional TRIZ is not normally very effective in dealing with such situations. As such, it is our hope that the new perception mapping tool offers a source of help to problem solvers operating in such environments.

1 Introduction

The first part of the “Applying TRIZ Methodology to Machine Maintenance†article dealt with the technical issues of a defect rate problem in a yogurt bottling plant (Reference 1). To recap briefly, the plant fills, labels and packs bottled food products for a variety of different customers. The plant has been operating for several years. Profitability has been good despite a defect rate of 7% averaged across its full range of output. Overall downtime averages around 5%. Competition has gradually been catching up with the plant, and in addition to a renewed marketing initiative, the management has decided that it needs to significantly reduce the defect rate and overall downtime.

The plant operates a 2-shift production system. Operators on both shifts are expected to record defects and their sources. The plant has a specific maintenance department responsible for setting machines and correcting problems.

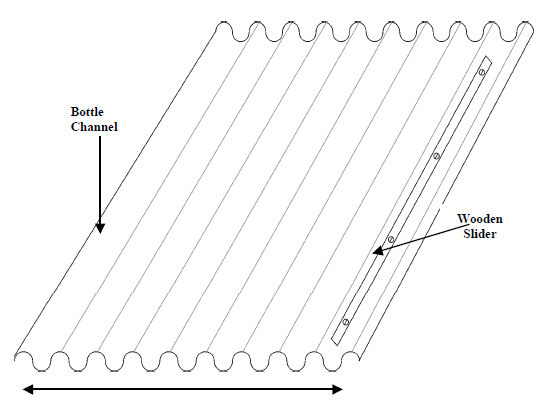

At the end of the first article, we presented technical solutions to the problems present in the plant. Some time after the presentation of these solutions it became apparent that the performance of the plant was not significantly improving. This despite the fact that all of the solutions had been deemed relevant and economically viable. As shown in Figure 1, for example, a significant source of downtime of the system was the fact that the Unscrambler machine contained wooden sliders that were shown through the function analysis to be responsible for an excessive and damaging action on the bottles. These sliders were known to break on an almost continuous basis. The Maintenance department logs in fact showed that repairs were required on an almost weekly basis.

Closer examination of the situation revealed that there were reasons for the poor performance that had nothing to do with the technical aspects of the design of the machines. For example, although the strategies recommended in the technical analysis would have removed the possibility of failure of the wooden sliders, none of these solutions had actually been applied.

In order to begin tackling this ‘lack of improvement’ situation, the four principle areas connected to the problem – Management, the Operators of the machines, members of the Maintenance Department and the local Trade Union (Figure 2) – were brought together. Although it appeared clear that everyone present was expressing a willingness to address the defect reduction issue, it very quickly became clear that not everyone was speaking as frankly as would have been expected in a truly impartial setting. It was decided that the four parties would examine the problem separately for a short while, recording their perceptions about the problem.

Perception Mapping Exercise

In these situations where different parties holding potentially very different views are involved in a problem and where emotions may be running high, the novel perception mapping technique (Reference 2) offers a systematic means of handling matters in an emotionally neutral environment. The tool builds on the flow-scaping method pioneered by Edward DeBono (Reference 3), adding to that method a number of TRIZ concepts. In this case each party was asked to construct a perception map by first recording answers to the question ‘How do we reduce downtime and defect rates?’. As there had been some reluctance for the different groups to talk openly, this part of the analysis was conducted with each of the groups working separately. Each group was asked to agree and record their thoughts and opinions. MagNotes (Reference 4) were used in order to facilitate easy communication of the findings at a later session when everyone came back together again.

The perceptions recorded by the management team were as follows:-

•Obtain better understanding of root causes

•Stronger ownership of processes by operators

•Accelerate response time of Maintenance Department

•Avoid repeating same mistakes/Introduce ‘lessons learned’ database

•Introduce formal SPC computer monitoring system

•Commonalise design of different bottles

•Introduce fully automated system

•Tie operator wages to defect and downtime

•Introduce formal quality training to operators

For the machine operators, the recorded responses were as follows:-

•Productivity demands push the system too hard and need to be reduced

•Replace ageing machines

•Improve response time of Maintenance Department

•Change design of bottles

•Automate machine setting adjustments between batches

•Increase shift handover overlap time- better communication between shifts

•Introduce ‘lessons learned’ system

For the members of the maintenance department, the recorded responses were:-

•Allow Maintenance to influence the design of the bottles

•Improve spares supply turnaround from machine manufacturers

•Replace ageing machines

•Reduce bureaucracy

•Give Maintenance authority to purchase spares

The Union representatives were less forthcoming than the other three parties. Their recorded responses were:-

•Better working environment

•Benchmark against comparable plants (to establish whether performance is normal)

•Replace ageing machines

•Disconnect productivity and jobs

For the next stage of the perception mapping process, all of the responses were collated and the four parties came back together to review what had been produced. The following Table 1 was produced as a means of highlighting which perceptions were common to which groups:

Apparent tensions during the bringing together of the ideas were reduced by carefully explaining that the recorded ideas were only perceptions and not decisions. The next part of the process then sought to highlight which of the perceptions were in conflict with one another. The group in fact identified two pairs of perceptions that were out of line with one another:-

a) the management perception that response time by the maintenance department was poor versus the maintenance department perception that bureaucracy was high

b) the management perception that the defect rate problem would be solved by automation versus the Union perception that any productivity improvement would result in loss of jobs.

Of the two, the group agreed that the second was the most serious. At this point in the perception mapping process, the group was asked to record the conflict and move on to the next phase. It was made clear that this step did not mean the conflict was being ignored, on the contrary, it was emphasized, the next part of the process would help later efforts to explore and hopefully resolve the conflict to the satisfaction of all.

The next part of the process then involved providing a unique identifier to each of the recorded perceptions. An A-to-V code structure was used as shown in Table 2 below. Also shown in this table is the result of the most important part of the process; the results of the group being asked the question ‘what does this perception lead to?’ for each of the perceptions in turn. Importantly, this task was performed collectively, with appropriate discussions taking place to ensure consensus in the opinions recorded. As it happens there was little disagreement over the answers obtained. If there had been (which seems to be the exception rather than the rule based on the evidence of many other real problem settings), then all of the different answers would have been recorded.

Identifiers G and V record the previously recorded conflict between the management perception that the defect rate problem would be solved by automation versus the Union perception that any productivity improvement would result in loss of jobs.

Having completed the table, the resulting perception map was constructed. As per the method described in Reference 2, this involves translating each perception statement into a symbol – here we used hexagons – and then connecting different symbols using arrows specified in accordance with the ‘leads to’ instructions. Because each perception has one and only one arrow leading from it, the resulting map must include at least one enclosed loop. As is sometimes the case, two separate loops emerged from this particular analysis. One of the loops (Figure 3) was seen to relate to what could be seen as ‘data’ issues:-

The team for the most part agreed with both the logic of the model and the need for a system of not only recording defects, but also which â€fixes†worked and which didn’t. The main source of disagreement came from the Maintenance department. No one from the Maintenance team was prepared to discuss why they disagreed.

The second loop system was rather more complicated. Upon downstream analysis this loop was more focused towards what the group saw as the people issues of the problem situation.

The perception map for this second loop is reproduced in Figure 4 below:-

The perception map revealed a very interesting self-re-enforcing loop: This loop centred around the benefits of management giving more control of the manufacture process to the operators. It also revealed perception C ‘accelerate maintenance response’ as the perception that acted as the most significant ‘collector point’ for other perceptions. Again according to the process, these collector points are significant.

Upon viewing the loop, the Management team was immediately concerned that it contained the perception (stated by the operators) that the current system was being pushed too hard. In fact they found it very difficult to accept the truth of the suggestion. The loop appeared to them to suggest a downward spiral of operators improving their working environment by setting themselves easier targets. The operators, in contrast, saw the situation the other way around – that by giving them ownership of the process (that after all only they properly understood, they argued), they would generate increases in productivity. They pointed to perception H ‘tie wages to defect and downtime’ – connected to the ownership perception, B as the mechanism through which the management would ensure they got what they wanted.

The significance of the loop was further emphasized when the two sides of the G/V conflict were identified within the map as shown in Figure 5. Also felt to be significant in the chain of perceptions connecting the two ends of the G/V contradiction was the presence of the collector point C.

When interpreting perception maps in general, in the situation where two sides of a conflict both lead to the same perception – as was present here – it is usually the case that the win-win solutions will emerge by breaking the chain of connections in some way. In many senses this breaking of connections is similar to the strategies used by the Theory of Constraints (TOC, Reference 5). The main difference between the two approaches, however, is that the TOC ‘Evaporating Cloud’ tool simplifies conflicts to examine just two different connection paths, whereas the perception mapping tool provides a much more flexible means of mapping all of the perceptions relating to a situation.

Figure 5: Key Re-enforcing Loop of the Integrated Perception Map and Relation to Identified Conflict The eventual key to the resolution of the overall problem came through examining Figure 5 and focusing on the presence of the collector point C ‘accelerate maintenance response’ in the conflict chain. The conflict between C and V ‘disconnect productivity and jobs’ immediately put the spotlight on the Maintenance department and their reluctance to agree to the need for recording lessons learned in the earlier (Figure 3) data loop discussion.

As is often the case in these situations, when the ‘real’ problem emerges, the solution becomes almost self-evident. In this case, it became apparent from the perception map that the real problem was that by reducing defects the Maintenance department believed they were putting themselves out of a job. Prior to the perception mapping sessions, this connection was something that they had been extremely unwilling to admit or discuss. In fact, it was never even something they felt willing to write down while recording their perceptions during the idea generation phase of the analysis. But now the analysis had brought the issue clearly to light for all to see; eliminate defects and Maintenance disappears. Or rather, Maintenance perceive that they will disappear.

Now that the ‘real’ problem was out in the open, the Maintenance people also revealed that not only were they afraid about their jobs, but that they were also in the shorter term worried about losing their overtime.

In emotive situations like this, it was decided that a win-win solution was the only way of proceeding with everyone operating in a positive frame of mind. At this point it was decided to see what the Business Contradiction Matrix (Reference 2) had to suggest. Figure 6 illustrates the conflict pair that the group agreed best described their conflict

The group then used the recommended Inventive Principles as a focus for brainstorming possible solutions to the situation (no one in the group had received any prior TRIZ training and so the session was preceded by a short description of the Principles). After around an hour of idea generation and evaluation, the group collectively agreed that Principle 13, The Other Way Around’ was the one that had offered the best overall solution direction. Ideas generated from other Principles also had something to contribute to the detailed implementation, but the main idea was that instead of rewarding the Maintenance Department for maintaining the plant, they should be rewarded for not having to conduct any maintenance. In other words, the lower the defect rate, the more the ‘Maintenance’ Department would be remunerated. With this simple reversal in thinking, the Maintenance Department could suddenly see that there was a lot of merit for them to support the earlier discussion concerning lessons learned records and further for them to pro-actively seek to improve the system.

In fact this solution and the perception map that facilitated its emergence permitted everyone to win; the Maintenance Department had the opportunity to earn more; the operators got the opportunity to earn more because lower defects meant higher productivity for them; the managers won because they were getting better productivity and were no longer effectively paying twice for defects (once for the defect, and once again to pay the Maintenance department to fix them); and the Union won because jobs were stable and likely to become more stable as productivity and hence the effectiveness of the business improved.

Conclusions

The perception mapping tool presented here is something that has its roots in work by Edward DeBono. The incorporation of TRIZ thinking seems to have elevated the capability of his original ‘flow-scaping’ method to a higher level. As this case indicates, it is a tool that enables groups to work on emotionally charged issues in a rational and systematic manner. In this particular case the tool went so far as to define a problem that would otherwise not have been elicited from the group. Total time spent explaining the mechanics of the tool to the groups was 30 minutes.

The case also suggests the importance of resolving problems in win-win ways. It is still early days for the business Contradiction Matrix tool, but this case served to demonstrate that it was possible to use the tool with a diverse group containing no prior knowledge of TRIZ and to generate a win-win-win-win outcome that looks set to be deployed in the near future.

Problems involving people and personalities are always complex. Attempts to treat them otherwise are doomed to fail. The Perception Mapping tool is an attempt to manage the complexity of these situations and to allow those involved to deal with issues in an emotionally neutral and forward thinking atmosphere.

References

1) Cooney, J., Mann, D.L., Winkless, B., ‘Case Study Applying the TRIZ Methodology to Machine Maintenance’, TRIZ Journal, August 2003.

2) Mann, D.L., Dewulf, S., ‘Hands-On Systematic Innovation for Business and Management’, CREAX Press, October 2003.

3) DeBono, E., ‘Water Logic’, Viking, 1993.

4) Blake, A., Mann, D.L., ‘Making Knowledge Tangible’, TRIZ Journal, December 2000.

5) Stratton, R., Mann, D.L., ‘Physical Contradictions and Evaporating Clouds – Case study Applications of TRIZ and the Theory of Constraints’, TRIZ Journal, April 2000.