The Study of Problem Solving by TRIZ and Taguchi Methodology in Automobile Muffler Designation

Editor | On 13, Mar 2004

Tzann-Dwo Wu

Assistant Professor, Department of Industrial Management, Tung-Nan Institute of Technology Taipei, 222, Taiwan

Abstract

Deming developed a new quality-improving concept, which extended quality inspection to statistic process control (SPC). Taguchi is further to improve quality techniques by production step to trace back to the design phase. Design phase then so-called off-line quality control, is to point the source principal superintendence, introduce quality into “product and manufacturing processes design phaseâ€, can reduce the cost and stilted qualities significantly.

The activities of off-line quality control are promoted by Design of Experiments (DOE), the best products and manufacturing process in strike out (i.e., engineering optimization). This study is guide “TRIZ theory and Taguchi methods†in automobile muffler design phase to fit the requirements of “engineering optimization designs. For practical accreditation in muffler designation, the process of problem solving by TRIZ and Taguchi method and the procedure of applying Taguchi method to parameter and tolerance design were established. Base on BEM, characteristics and performance analysis of noise reduction and transmission loss and “80-20 Ruleâ€, we got priority for automobile muffler designation: 1st. Dual-perforated intruding tube muffler; 2nd. Simple expansion with dual ¼ L intruding tube chamber; 3rd Dual-Perforated intruding plug tube muffler.

1. Introduction

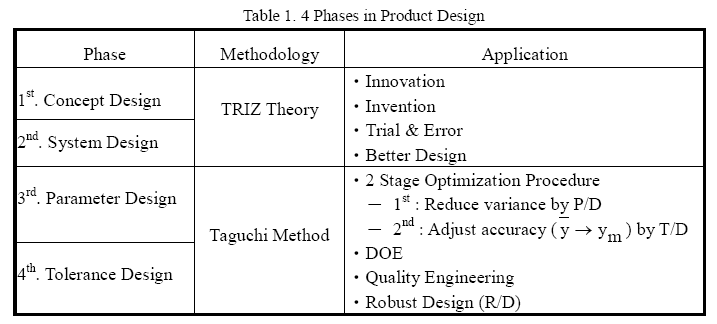

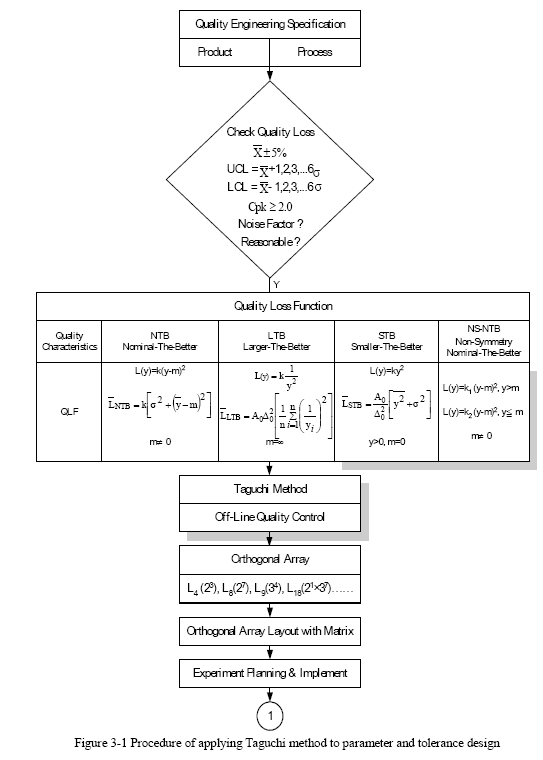

Deming developed a new quality-improving concept, which extended quality inspection (on-line quality control) to statistic process control (SPC). Taguchi is further to improve quality techniques by production step to trace back to the design phase. Design phase then so-called off-line quality control, is to point the source principal superintendence, introduce quality into “product and manufacturing processes design phaseâ€, can reduce the cost and stilted qualities significantly. The activities of off-line quality control are promoted by Design of Experiments (DOE) [2, 3] , the best products and manufacturing process in strike out (i.e., engineering optimization). And the design phase has four: (1) conceptual design; (2) system design; (3) parameter design; (4) tolerance design. This study applied “TRIZ theory and Taguchi methods†in automobile muffler design phase (as shown in Table 1.) to fit the requirements of “engineering optimization designs†(its process detailed as Figure 1).

1. Concept Design (C/D)

Design engineer try to find more efficient “quality loss function†(e.g., low sensitivity and small noise factor) by utilizing innovation, invention, creativity, QFD, Kano Model[5] , brainstorming techniques. To stimulate new concepts happened, create prototype and product and finally select the optimum alternative by trial and error method.

2. System Design (S/D)

While designing and developing products or service should consider its basic function, performance, VOC and latency risks. Also steer the input and output of the correlation request and designation [1] , as the Table 2.

3. Parameter Design (P/D)

P/D has the same meaning with Robust Design (R/D); minimize quality losses in products or in the manufacturing process (i. e., N/F Sensitivity), make quality reaction value (yi) to meet target value (ym).

‧Min(N/F Sensitivity)→ Min(Quality Loss)

− Reduce the cost of manufacturing or quality loss (QL) (replace by lower class kit/material).

− Deciding the best combination of parameters.

4. Tolerance Design (T/D)

*Reduce QL that performances of product change caused.

*Reinforce cost of manufacture, discreetly choose the high class material factor of reducing the tolerance.

2. TRIZ Theory

TRIZ (Teoriya Resheniya Izobretatelskikh Zadatch) theory [4] was created by Russia inventor-Genrish S. Altshuller and its research fellows in 1946. They have analyzed and integrated 1,500,000 patents since 50 years ago. Also assume “universe exists an universal inventive principle, it’s a base of innovation, invention and creativity for new techniquesâ€, and detects two phenomena: (1) exist a basic and common question and its problem solving models for the different creative invention questions; (2) the same problem solving alternative can multiplicity uses in resolve the problems that corresponding different period, different province station come. TRIZ definition for: (1) Theory of Inventive Problem Solving (TIPS) and tool; (2) have the cerebration and problem solving models (as Figure 2.) of the systematic, repeatability, reliability [4] ; (3) TRIZ 40 principles versus 39×39 rank engineering parameters matrix (P improving ×P Avoiding Degeneration) (i.e., conflict matrix), to solve the engineering conflict, technology contradiction and promote quality and efficiency.

2.1 Technology System

Any article can run certain kind of function, call it “technology systemâ€. And the technology system can be constituted by one or several subsystems, and its hierarchy organization also has two subsystem of the components at least. When the technology system generates badly function or don’t have the expectancy function, then have to improve it. Generally, the systematic facilitation really can’t be well timed by the trial and error method and accurate to find out root-causes.

2.2 Technology Contradiction

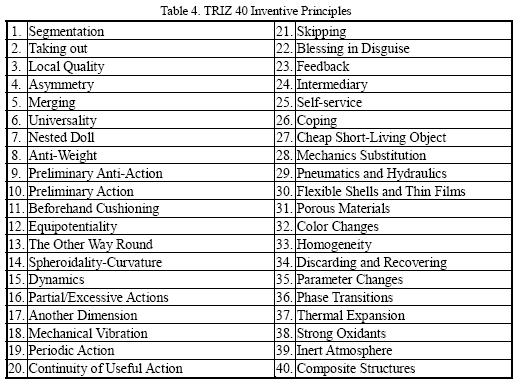

When improving certain a parameter attribute for system, will come another a parameter characteristic deterioration, the technology contradiction that call. The former is an Improving Parameter (IP), the latter then calls the Avoiding Degeneration Parameter (ADP). Altshuller summarized 39 kinds of engineering characteristic parameters from 1,500,000 patents database (as Table 3.) and 40 inventive principles (as Table 4.). When the technique system arises problem, the project team can screen IP and ADP by brainstorming and create “conflict matrix†(as Table 5.), find out the accommodation inventive principles or solutions from Altshuller conflict table subsequently, then proceeding concept design and system design for automobile muffler (as Table 6, 7.).

3. Taguchi Method

3.1 Noise Factor(N/F)

Product at the practice use, its quality characteristic or response value result from product function change, target value drift and quality loss because some rhea factors (product, environment, time). Its type has four: (1) External Noise: generate dissociation is because of the product praxis environment, bear the burden and transaction methods; (2) Unit- to-Unit Variation: can’t avoid on the manufacturing process its dissociation; (3) Deterioration product quality would be recession or inferior by components decade and time rapid growth; (4) Process Noise: includes external to the process, process no uniformity and process drift. Therefore, how to judge by engineering experience, identify and minimize noise factor are good for improving quality loss.

3.2 Quality Loss Function (QLF)

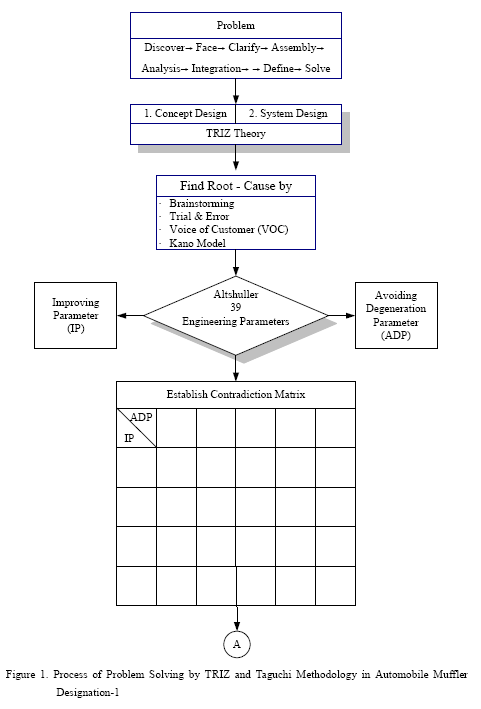

Taguchi recognizes the customer’s desire to have products that are more consistent, part-to-part and a producer’s desire to make a low-cost product. The loss to society is composed of the costs incurred in the production process as well as the costs encountered during use by the customer (repair, lost business, etc.). [6] Taguchi defined quality as the loss a product causes to society after being shipped, other than any losses caused by its intrinsic functions. [7] . In product life cycle, quality characteristics or response value (y) will deflect from ym (target value) caused by product, environment, time dissociation (i.e., out of product specification or quality loss). The exact nature of the loss function for every quality characteristic is difficult to determine. Taguchi assumed that losses could be approximated by a quadratic function so that larger deviations from target cause increasingly larger losses. OLF contain four kind types: (1) Nominal-The- Best (NTB); (2) Larger- The- Best (LTB); (3) Smaller- The- Best (STB); (4) Non- Symmetry- Nominal-The- Best (NS-NTB) is shown in Figure 3.

3.3 Orthogonal Array Layout

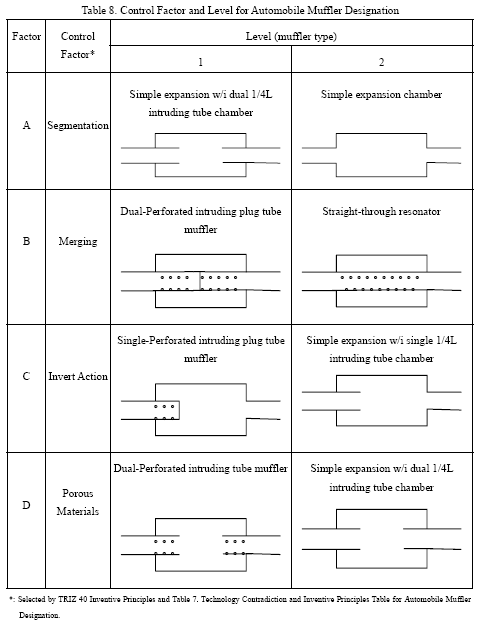

Taguchi is for reducing and simplifying experiment’s frequency and treatment, toeing acquires the best factors and effects combination. Orthogonal array are made up of factors and levels, its common usage : L4 (23), L8 (27), L9 (34), L16 (215), L18 (21×37), L27 (313). In this study , L8 (27) was used to layout control factors (segmentation, merging, invert action, porous materials) and levels (1, 2) for automobile muffler designation (as Table 8., 9).

3.4 Signal-to- Noise Ratio (S/N ratio)

Taguchi considers “good quality†should meet: (1) the average value of quality characteristic is in accordance with the target value; (2) the variation of quality

characteristic is the smaller the more addicted Taguchi created S/N then can consider the average value and variance simultaneously, and to measure system reliability. When S/N

ratio is higher, the product quality is higher, and the quality loss is smaller. Finally choose the highest S/N, and then reorganize the best factor and level combination. S/N contain three types, knowing well as the Figure 3. In this study, we used STB (Smaller-The-Better) to calculate S/N, η , ANOVA and draw response graph for automobile muffler type designation, then get the best combination (A1 B1 C1 D1) (shown in Figure 4., Table 10.).

4. Muffler Designation

4.1 Muffler Principles and Theory

The cardinal noise in metropolitan district derives from the motor vehicle exhaustion tail pipe then muffler uses to provide a restraint or controlling function for noise reduction.

Muffler divides into two types: (1) reactive muffler: make use of acoustics impedance to reflect sound source; (2) dissipative muffler: transform sound energy to heat by lining absorbed materials.

Dissipative muffler is in using process, the reasons are: (1) the pore of the lining absorbed material jammed; (2) high temperature make material changed in character; and decreased sound restraint effect. It’s not available for high temperature and air pollution (CO, HC, NOx, PM) environment. For this, the special chosen of research strikes “reactive mufflerâ€

to progress development and design the optimized combination by TRIZ and Taguchi method.

4.2 Noise Reductions and Transmission Loss

For the theoretical study, we apply BEM (Boundary Element Method) to analyze 8 types of reactive mufflers used in automobile designation (shown in Table 11.). The estimation

of TL (Transmission Loss) is based on the same conditions:

1.specification of muffler

*inlet tube diameter

*outlet tube diameter

*tube thickness

*hole diameter

2.mean flow / Mach number

3.mean temperature

4.mean length / diameter/ porosity for perforated intruding tube

4.2.1 Theoretical Formulation

1.Simple expansion chamber

(1) BEM theoretical formulation with deriving process

(2) Calculate TL

(3) Draw characteristics figure with TL (dB)- Frequency (Hz)

2.Simple expansion with single ¼ L intruding tube chamber

3.Simple expansion with dual ¼ L intruding tube chamber

4.Straight – through resonator

5.Single – Perforated intruding tube muffler

6.Dual – Perforated intruding tube muffler

7.Single – Perforated intruding plug tube muffler

8.Dual – Perforated intruding plug tube muffler

4.2.2 BEM formulation:

Sound wave spreads in space, under controlling for sound pressure, its running pattern can be described by wave equation. Suppose sound wave as the harmonic motion, then sound wave motion satisfy Helmholtz equation [8, 9, 10] :

single acoustic space directly, so need to divide several surfaces by geometric shape or boundary condition separately.

In Table 11, type 1, 2, 3 can directly analyze by single acoustic space, type 5, 7 analyze by dual acoustic space, and type 6, 8 need to partition three zones. Firstly, apply formula (2) to each acoustic space, can get the relationship between sound pressure and pressure gradient (or velocity) respectively. Then, combined an enlarged acoustic space (i.e.

muffler chamber) which included inlet and outlet by the same opening pressure and velocity or acoustic impedance condition of perforated intruding tube Finally, can obtain pressure vs. velocity transformation formula between inlet and outlet of muffler [8, 9, 10] .

4.2.3 Numerical simulation and analysis

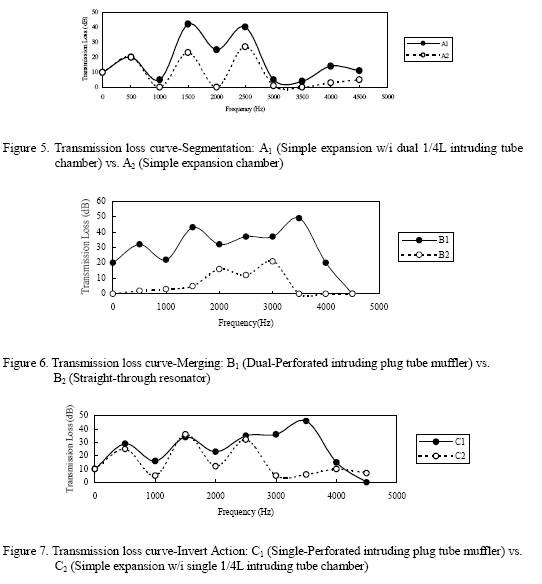

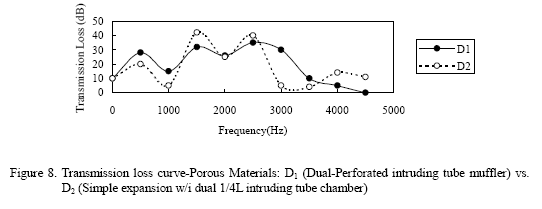

To perform the numerical simulation by formula (4), the related specifications of muffler are identified as follows [11] : (1) expansion chamber length Lc=16cm; (2) expansion chamber radius rc=6cm; (3) inlet and outlet intruding tube length Li=4cm; (4) intruding tube diameter Ri =2cm; (5) intruding tube thickness ti =1mm; (6) drilling hole diameter Rh=2mm; (7) mean flow velocity M=0.1; (8) porosity σ=0.05. Table 11.shows the transmission loss (dB) of 8 types muffler at different frequency. We summarized two states for the optimized designation of muffler: (1) at 1,500Hz-muffler type 8>3>2>7>6>5>1; (2) at 2,500Hz-muffler type 6>3>8>7>5>2>1.Base on characteristics and performance analysis from Figure 5.-8.,“80-20 Rule†and “Benefit and Cost analysisâ€, we got priority for automobile muffler designation:

1st . 6. Dual-perforated intruding tube muffler (D1)

2nd. 3. Simple expansion with dual ¼ L intruding tube chamber (A1)

3rd .8. Dual-Perforated intruding plug tube muffler (B1)

5. Conclusion

In this study, we created a problem solving skill by integrating TRIZ and Taguchi methodology to fit the requirements of “engineering optimization designsâ€. For practical accreditation in muffler designation, the process of problem solving by TRIZ and Taguchi method and the procedure of applying Taguchi method to parameter and tolerance design were established. Base on BEM, characteristics and performance analysis of noise reduction and transmission loss and

“80-20 Ruleâ€, we got priority for automobile muffler designation: 1st. Dual-perforated intruding tube muffler; 2nd. Simple expansion with dual ¼ L intruding tube chamber; 3rd Dual-Perforated intruding plug tube muffler.

Reference

1. ISO 9001: 2000 Quality Management System – section 7.3.2, 7.3.3, 7.3.5, 7.3.6.

2. C. F. Jeff Wu and Michel Hamada, â€Experiments Planning, Analysis, and Parameter Design Optimization,†John Wiley & Sons, Inc., 2000, pp.1-17.

3. S. W. Cheng, “Implementation of DOE: Objective, Planning, and Analysis, â€Institute of Statistical Science, Academia Silica, 2002.

4. TRIZ Journal, www.the-trizjournal.com

5. Noriaki Kano, “Successful Business Strategies in Changing Age: Attractive Quality and Its Creation, “Attractive Quality and Six Sigma Seminar, BMG, 2003, pp.24-64.

6. Phillip J. Ross, “Taguchi Techniques for Quality Engineering,†McGraw-Hill International Company, Inc., 1996, pp.3-20.

7. James R. Evans, William M. Lindsay, “The Management and Control of Quality,â€

South-Western College Publishing, 1999, pp.399-405.

8. Laurence E. Kinsler, Austin R. Frey, Alan B. Coppens, James V. Sanders, “Fundamentals of Acoustic,†John Wiley & Sons Inc.,1982, pp.124-139.

9. C. -N. Wang, C., -Y. Liao, â€Boundary Integral Equation Method for Evaluating the Performance of Straight-through Resonator with Mean Flow,†Journal of Sound and Vibration 216 (2), 1998, pp.281-294.

10. Chao -Nan Wang, Yih-Nan Chen, Jean Yih Tsai, â€The Application of Boundary Element Evaluation on a Silencer in the Presence of a Linear Temperature Gradient,†Applied Acoustics, 62, 2001, pp.707-716.

11. Chao -Nan Wang, â€A Numerical Analysis for Perforated Muffler Components with Mean Flow,†Journal of Vibration and Acoustics, Vol.121, 1999, pp.231-236.