The Logistic Innovation Approach and The Theory of Inventive Problem Solving

Editor | On 13, Jan 2006

By: Odair Farias

ABSTRACT

This paper proposes some strategic ways to logistic innovation through the Russian methodology – “Rechénia Izobretatelskih Zadátchi Theory – Triz†(Theory of Inventive Problem Solving). Assets related to logistic evolution and its definitions, as the ultimate conception of supply chain, have typed this search and stimulated the systematic assessment model by performing an exploratory study of their engineering parameters. The heuristic analysis of generic supply chain performance was conduced as trade management, what increases the supply chain scope settling sustained strategic paths. Inventive principles closely related to the best logistic practices have presented innovative and alternative results, and also contribute to the occidental development of the Russian methodology.

INTRODUCTION

The accelerated evolution that we are experiencing nowadays has technical innovation as the main set of devices and methods to boost organizations. Innovation is part of the daily social activities and, especially, of companies, by changing the producing processes and the models of products that assimilate technological progress. Real diffusion of innovation is, thus, brought on, by the support of technological changes in the producing systems and in the development and arrangement of the territories, by means of new areas of innovation, as well as other implications arisen from innovation. Innovation has become an important topic or a pre-eminent issue in modern times. Some say that present innovations, in this era of new technologies allied to telecommunications and to computer science, significantly alter social structures, changing the ways of producing, circulating, distributing and consuming goods, services and ideas; or, moreover, that territories and modern societies are being reorganized in an essential manner by means of scientific and technological innovations.

At the beginning of this millennium, the business world saw the world’s biggest retailer make use of a central data base with a capacity of a few hundred terabytes, that is, approximately one million times more information than the human brain can retain throughout an entire life. Even so, authors such as Stephen Hawk and Roger Penrose categorically state that those powerful mainframes might never supersede the human being’s creative capability for innovating. Innovation is presently the biggest challenge that all companies will have to face no matter how large they are.

Upon the rupture of countless paradigms and continuous innovation in the logistic processes, special emphasis is being given to supply chains in general. This has motivated the detailed conceptual study of these chains as well as their association with substantial gains in the strategic alignment and in the companies’ competitiveness. This scientific article proposes to assess Brazilian logistic systems and their supply chains by an innovative methodology, by suggesting ways to effective logistic innovation and, among the major segments of logistics, by pointing out the ones bearing the strongest innovation potential.

Conceptual Model of Supply Chain

The term “Supply Chain†aims at naming the structure – as a whole – adequately designed to fulfill the demand of a specific market (Slack, 2002). This concept assumes the coordinated adoption of appropriate strategies between business partners. The strategic process of supply chain management gathers suppliers, producers, shippers, distributors, and clients round a dynamic with a constant flow of information, products and funds, which add value for customers and other participants (Lambert, Cooper and Pagh, 1998). By defining value chain as a set of stages that, in fact, add value, this concept aims at eliminating the steps that do not add value, such as inspections, stocks and material transportation (Handfield and Nichols, 1999).

In order to globally visualize a supply chain, a priori, it is necessary to know the cycle of the product lifetime, and, afterward, analyze the interaction between its participants. Given the conceptual and strategic importance of the supply chain, at the beginning of 2005 the former CLM (Council of Logistic Management) had its name changed for CSCMP (Council of Supply Chain Management Professionals); thus making the newest conceptual reference come up: Supply Chain Management comprises planning and management of all activities involved in the search and acquisition, conversion, and all logistic management activities. It is important to include coordination and collaboration between the participants of the links; and these can be suppliers, intermediates, third-party logistic service and customers.

In essence, Supply Chain Management integrates the supply and demand management into and between companies. To explain the main concepts of this integrated supply chain, the Bowersox’s model points out, in the following Figure, the interaction between flows of materials and location of the stakeholders.

Mentzer (2001) states that researches on supply chain management display a huge mistake concerning the several and varied adopted definitions because, in fact, they have been trying to define two concepts using only one term: supply chain management. The authors suggest that the phenomenon should be treated and studied according to two concepts and by using two terms: orientation towards the supply chain that, firstly, in fact, is the definition of SCM as a philosophy bearing the idea of viewing supply chain coordination under a systemic perspective, and, according to that, each one of the tactical activities of the distribution flows are analyzed in a wider strategic context; and, secondly, SCM, now meaning the implementation of that orientation through the several companies in the supply chain.

Another important reasoning stated by (Mentzer, 2001), is related to supply chain management aims, which, according to them, can be functional and organizational. The SCM functional aim is related to the definition of which traditional functions of business are comprised in the SCM implementation process; while the organizational aim cares about defining which sorts of relationships between companies are relevant to the several companies that participate in the supply chain management implementation and process. These authors conclude that the SCM functional aim should comprise all traditional functions of business: marketing, sales, research and development, forecasting, production, purchases, logistics, information systems, finances and services to customer. As for the organizational aim, the authors consider that the network is the most adequate and accepted organization of the supply chain management.

Redefining the supply chain is no longer a risky and state-of-the-art technology activity. Companies, in many sectors, successfully rebuilt their supply chains and now restructure the way they deliver their products and render services to their clients. As more and more companies design their supply chain and alter the competitive scenario, being inside an efficient and effective supply chain is going to be a critical factor for the survival of the company.

There is a series of obstacles to be overcome in order to carry out the innovative performance of the supply chain, and we could mention, among them, setting an adequate management environment and new attitudes towards managing the material, information and resource flow.

Supply Chain Performance

For Dornier (2000), logistics refers to management of flows between business functions. A modern definition of logistics encompasses a wider range of flows than it did in the past, including several manners of product transportation and information assessment. A more dynamic view of product flow and a broader scope of the extended chain are included in the new concepts, associated to efficient supply chain management. Just like in war logistics, (Morales and Gear, 2003), strategic and operational bottle-necks often represent a “lost link†in the supply chain. Therefore, flow management must be in light of the partnership between consumption and demand.

Nowadays, with the present scientific and technological resources, managing logistic flows has become more important than managing stocks, bearing in mind, from the beginning to the end of the supply chain, all the countless performance measures. To assess performance and logistic performance in the supply chain engineering parameters have been adapted to the performance measures adopted in recent studies in Denmark, Germany and China (Larson and Gammelgaard, 2001; Andréa and Hanf, 2004 and Lai and Cheng, 2003). Some considered parameters have gained special attention in studies stating that the best supply chains are not only fast and economical. They are also agile, adaptable and aligned to the participants’ interests (Lee 2004). Due to this performance profile, these competitive supply chains have been called “Triple-A†supply chains. According to recent studies, responsiveness, flexibility, velocity, dependence and continuous sensitivity towards the costs will be the guides of the competitive advantage within the next years (Bowersox and Closs, 1999).

Among the major performance measures used in the assessment of a logistic system we can highlight: reliability, productivity, profitability, maintenance, stock management, integration level, quality, innovation, risk management, cost management, time management, support, service level, and others. The new economic features in the world are changing the global logistic flows; their intensity, velocity, physical needs, and so forth. This is one of the main trends in the supply chain flows and traffic intensification, and, in many cases, it is causing restrictions to the infra-structure capacity. This overload intensively affects all segments of the logistic system and creates, in some cases, an international flow unbalance. This phenomenon have corporations change their strategy and to search for new solutions. “… Even though a problem seems insuperable, there is a simple and powerful solution.

However that solution can only be found if the aim is increased; only if the problem is seen as part of a wider scenario†(Goldratt 2003).

Logistic innovation and competitive increments.

For many years, the people responsible for the logistic operations have been using tacit innovation for their procedures by knowing, not in detail, but at least part of their customers’ desires concerning logistic services and added-value. Nowadays, many of these

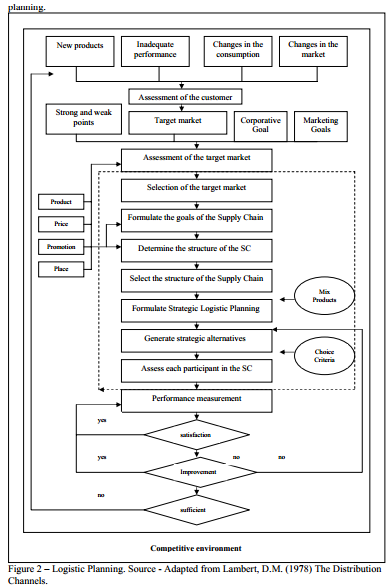

innovations are well studied and documented making replication of the best practices making easy replication of the best practices, and, little by little, this is turning logistic innovation into a more pragmatic subject (Flint et al, 2005).Similarly, the majority of the organizations have strengthened by answering to marketing environment changes, determining a view, a strategy and even an adjustment to the processes in a collaborating way, especially in the largest and most bureaucratic organizations. Countless researches have shown that logistic innovation arises from deep insights originated in the continuous relation with customers. Interpretation and dissemination of information about those insights lead to the apprenticeship of new practices related to these innovations, an also make innovation processes themselves more familiar. Innovation, development of new products, market orientation, value added to the customer, and organizational apprenticeship; significantly revise innovation processes, idea generating processes, market intelligence and dissemination processes. For Ljungberg and Larsson (2001), Larsson’s thinking process school defines business process as: “The set of basic activities repeatedly used and allied to information and resources in order to transform raw material into finished product, extending from the identification point up to the satisfaction of customers’ needs.†In that way, productivity, quality and costs reduction, although they should not be ignored by managers, are no longer competitive advantage generators, once they have become the required minimum for the company’s survival. The set of those basic requirements and of the competitive differentials must be included in the integral logistic planning, as explained by (Stock and Lambert, 2001) in the following flowchart. The organization management may decide that the long term goals ensure competitive advantage, by focusing on the clients’ needs and capitalizing on opportunities. The strategic logistic planning can anticipate present and future expectations, including financial implications related to the necessary resources. From this point on, within the ambit of logistics, continuous commitments in the strategic planning can be subdivided into three major elements: long term goals, means to ensure those goals (value, services to client, etc.), and the process to ensure those goals (anticipation). Neglecting the need to assess future scenarios makes it necessary to fight important “firesâ€, confirming the importance of strategic

The great advantage of strategic planning lies in setting performance assessments for the company’s process by taking the necessary actions. As at Porter (2001), the ability to share activities in the value chain is the basis of managerial competitiveness, because sharing highlights competitive advantage by increasing differentiation.

The Theory of Inventive Problem Solving: Triz

Common problems within the ambit of the supply chain planning have widely-known solutions and can be easily found in the books. However, the complexity of contemporary chains and their challenges require equally complex and innovative solutions. These solutions are not often in the reference books, but bear in the solution to analogous problems the possibility of an inventive solution.

Historically, as long ago as the IV century, an Egyptian scientist named Papp suggested that there should be a science called heuristics capable of solving inventive problems (Altshuller, 1994). In modern times, inventive problem solving has fallen into the field of psychology, where the links between the human brain, the “insights†and innovation are studied.

Methods such as “Brain storming†and “Trial and Error†are commonly suggested. In this case, problem solving shall depend on how to use tools such as “brain stormingâ€, intuition and creativity.

An important issue here is that such psychological tools are quite frequently difficult to transfer to other people in the organization. And furthermore, there is what is called psychological inertia, where in a biased way, the solutions being considered are usually within one’s own experience and do not look at alternative technologies which develop new concepts.

Genrich Saulovich Altshuller, born in Tashkent in Russia in 1926, studied the Theory of invention and, by researching thousands of patent certificates, developed the methodology. “TRIZ (Rechénia Izobretatelskih Zadátchi Theory – Theory of Inventive Problem Solving), is a systematic human-being-oriented and knowledge-based methodology†(Savransky 2000).

His Theory defines inventive problems as those whose solution causes new problems to emerge. In his studies, Altshuller came across several types of solutions and, furthermore, the solution to countless contradictions. Triz was first introduced in the United States in 1991 and is based upon the study of 1.5 million patents, 400,000 of which are considered the world’s most inventive ones. Triz offers an extremely revolutionary knowledge-based way of thinking, by verbalizing and quantifying the human experience in inventing. This creates an analytical discipline for inventive problem solving that overlay engineering system contradictions.

There are five levels of problem solving:

a) The Standard Solution – The solution that resides within the specific science directly related to the problem (in the case of this study the transportation engineering and logistics). It represents 32% of the solutions.

b) Change of a System – Pertains to the most difficult problems that require a detailed “Trade-off†study, but still bearing the possibility of being solved by science. It represents 45% of the solutions.

c) Innovation – The solution is outside the problem-related science. (Triz) It represents 18% of the solutions.

d) Invention – The solution is found in science among the most rarely used systematics. (Triz) It represents 4% of the solutions.

e) Discovery – The solution resides in recently discovered phenomena and solutions. (Triz)

It represents 1% of the solutions. Levels of discovery 1, 2 and 3 represent the transference of solution from a field to another. This means that 95 % of the inventive solutions in any field have once been discoveries in other fields.

Concepts of Triz

The fundamental concepts of this Theory are ideality, contradiction, resources and inventive principles. Ideality, for example, is defined as the quotient of the sum of the technical system’s useful effects, divided by the sum of the harmful effects of the system.

Ideality = ∑ Ui / ∑Hi

Useful effects comprise all good results available in the system and harmful effects comprise undesirable inputs such as costs, energy consumed, pollution, danger, etc. From the concept of ideality, the ideal final result is defined as a solution with which the specialist intends to achieve the solution to the problem;

it is arbitrary and closer to the ideal than the present solution (Carvalho and Back, 2001). Contradictions are conflicting requirements regarding the same system, whereas resources are elements of the system or of the surroundings that, yet, have not been used for executing useful functions in the system. Both the solution to contradictions and the use of resources causes the system to be closer to the ideal. On the other hand, the inventive principles are either heuristic or suggestions about possible solutions obtained from the generalization and gathering of solutions repeatedly used in the creation, development and improvement of technical systems of different fields. Altshuller analyzed more than one million patent certificates trying to sort them by categories, being of no importance the kind of problem, but, in fact, the kind of solution that is used, thus defining the common principles and the laws of evolution of systems.

Presently this methodology has been widely used for the development of new products and as an example we could cite Chrysler corp., Mitsubishi, Ford Motor co., Johnson & Johnson, Rockwell, Unisys and Xerox. The leading tools are: Concept of Ideality, Contradictions Matrix, Su-Field (Substance-Field) Analysis, Use of Resources, Laws of Evolution and ARIZ.

Inventive Principles

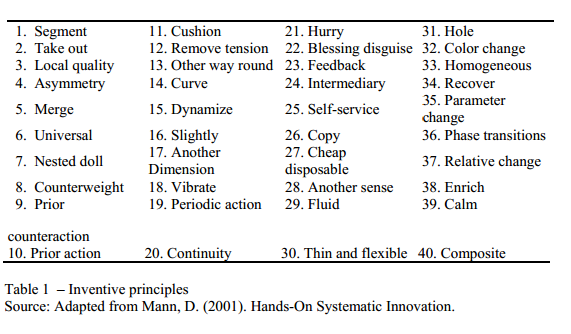

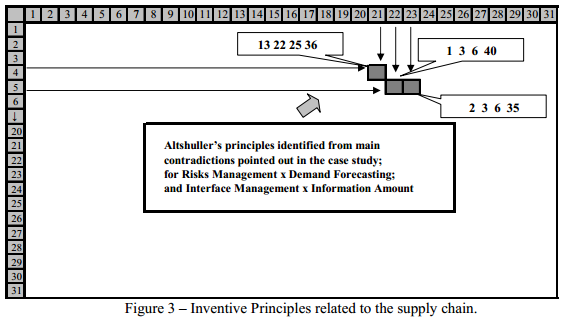

In order to propose solutions to the countless challenges in the SCs, The Triz methodology for inventive problem solving proposes the assessment of 31 parameters in its management process. Once the critical parameters intended to be improved and the parameters that potentially get worse by improving the former are identified, the system contradictions are duly established. These contradictions allow, through the contradictions matrix (Mcmxn, where m=31 and n=31 for Management Systems and m=39 and n=39 for Technical Systems), to identify, among the 40 inventive principles established by Altshuller, the most adequate for each contradiction (Mann, 2000).

Appositely, several principles proposed by the method are coincident, in essence, with the best modern practices implemented within the ambit of logistics.

Exploratory Methodology and the Interviewees’ Profile According to (Yin, 1994), the research should identify some situations in which all research strategies are relevant. “How†and “what†questions are formulated by inquiring a present set of events in which the researcher has little or no control. This investigative study aimed at identifying “how†occurs in the logistic chain, where the factors “what†are affected. As the study tries to search for those inquiries, this suggests the adoption of an exploratory methodology (Yin, 1994). Yin also reminds that exploratory studies are firstly useful in the generation of the investigated phenomena-centered hypotheses. Due to this, we also anticipated that the research would result in the emergence of hypotheses and in an additional theory to direct future researches in the field.

Identifying the behaviors of a phenomenon is essentially an exploratory activity in which the main goal is to refine the idea of the research in order to make a wider research easier (Kervin, 1992). In the face of this premise, the information collection stage can be considered as a preliminary investigation according to Emory and Cooper (1991), setting this up as an essential method for the research conduction. Although it is common that the exploratory research relies on the specialists’ opinions and the focus directed to the groups of the initial stage, this has not been considered in the present case.

Appositely, several principles proposed by the method are coincident, in essence, with the best modern practices implemented within the ambit of logistics.

Exploratory Methodology and the Interviewees’ Profile

According to (Yin, 1994), the research should identify some situations in which all research strategies are relevant. “How†and “what†questions are formulated by inquiring a present set of events in which the researcher has little or no control. This investigative study aimed at identifying “how†occurs in the logistic chain, where the factors “what†are affected. As the study tries to search for those inquiries, this suggests the adoption of an exploratory methodology (Yin, 1994). Yin also reminds that exploratory studies are firstly useful in the generation of the investigated phenomena-centered hypotheses. Due to this, we also anticipated that the research would result in the emergence of hypotheses and in an additional theory to direct future researches in the field.

Identifying the behaviors of a phenomenon is essentially an exploratory activity in which the main goal is to refine the idea of the research in order to make a wider research easier (Kervin, 1992). In the face of this premise, the information collection stage can be considered as a preliminary investigation according to Emory and Cooper (1991), setting this up as an essential method for the research conduction. Although it is common that the exploratory research relies on the specialists’ opinions and the focus directed to the groups of the initial stage, this has not been considered in the present case.

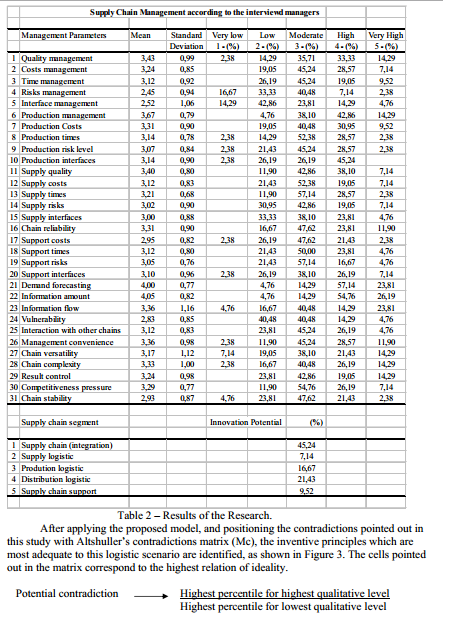

general cargo, manufactured products, and general supply. During the research follow up, we particularly identified the participation of logistics, marketing, trade and foreign trade departments, as well as higher administrative ranks (Presidents and executive directors). Although, in the supply chains we studied, the participants had extremely particular characteristics; overall as presented in Table 2, critical deficiencies and items highlighted were coincident in most of the cases, and this o favored the possibility of proposing common strategic principles and initiatives, through the used model. This low rate of dispersion at the assignment of the qualitative levels was confirmed by the research through a standard deviation between 0.7 and 1.1. Overall, all participants were attentive to the managerial profile of their chains, making the identification of the main contradictions between restrictions and potential restrictions. According to the ethical principles of the scientific research, after the data collection and insertion into the proposed outline, the database was handed in to the participating interviewees, without disclosing names or social registers. In general, the management parameters with the lowest qualitative assessments were risks management (4) and interface management (5). On the other hand, the parameters with the highest qualitative assessments were demand forecasting (21), information amount (22) and information flow (23); what caused us to consider the contradictions between risks management and demand forecasting, interface management and information amount and interface management and information flow as main contradictions of these systems.

According to the Percentile, the logistic segment pointed out as bearing the highest innovation potential was the supply chain and its interfaces, confirming the restriction highlighted in the interface management, and the second most frequent was distribution logistics, as presented in table 2.

After applying the proposed model, and positioning the contradictions pointed out in this study with Altshuller’s contradictions matrix (Mc), the inventive principles which are most adequate to this logistic scenario are identified, as shown in Figure 3. The cells pointed out in the matrix correspond to the highest relation of ideality.

Some contradictions in logistics are well known; however, the principles associated to the application of the model lead logistic planning towards really opportune strategies.

To optimize the risks management, the model proposed principles, among others, such as: 22 – “Blessing in disguiseâ€- This principle states that sometimes it is convenient to transform harmful actions in a way that they might produce positive effects, so that, from this principle, the negotiation agreements must be coupled with the “win-win†policy; 25 – “Selfservice†– This principle consists of enabling a system to perform its own functions or to selforganize, by quality circles, self-help groups, and also by reinforcing the organization structure itself by means of good performance. In the stock management, resources, such as bar code or RFID, give feed back to the database allowing updating in real time, as it is the case of the latter; and 36 – “Phase transitions†– This principle proposes that transition phases might be capitalized in order to clarify the real necessities of the system. Phases, such as conception, development, reengineering, etc., represent good opportunity for programming labor and raw material necessities, the establishment of the budget for the period, or investment necessities.

On the other hand, in order to optimize interface management, the model proposed principles such as: 1 – “Segment†– It consists of subdividing a system and proposes subdividing business into different product centers, autonomous profitability centers and sometimes proposes the startup of Franchises. The logistic systems can be subdivided, fragmenting the activities, creating specific competence departments and resolving occasional restrictions. Moreover, the principle proposes to utilize Kano’s diagram. 2 – “Take out†– This principle suggests that, under certain conditions, unnecessary or even harmful functions should be eliminated, making management more dynamic and proposes, in some cases, to implement lean manufacturing, Just-in-time stock management, as well as separating development and production activities. 3 – “Local Quality†– This principle proposes to increment specific individual parts, service customization, use of dedicated software, creation of strategic excel centers, factory location and distribution centers close to the customers. 6 – “Universal†– This principle proposes that the system should be enabled to perform multiple functions, eliminating the need to other associated systems. This includes labor force capacity diversification. 40 – “Composite†– Changing to a multiple element system where each element is optimized for a particular function is the main proposal of this principle.

This includes the adoption of multi disciplinary teams, training with several tasks, hire different personalities, and other alternatives such as the ones adopted in Six Sigma. Regarding the interface management related to information flow, the model also suggests the principle 35. “Parameter change†– Many parameters in the system can changed so that different result standards are obtained. Business management can be more or less flexible, more or less consistent, intensive or systematic depending on the expected result and the available resources to lead the system. Concerning logistic management, a series of more specific parameters can and must be adjusted, such as velocity, disposition (format), capacities, quality, resistance, and so many others that directly influence the system performance, and this can be previously verified when simulating the system dynamics.

Final considerations and proposals for Future Studies Nowadays the global market, more than effectiveness, requires a great deal of efficiency from the producing chain. In order to achieve this required efficiency level, supply chains and their respective stakeholders must be strategically aligned, as in the proposed model. With concerns about this requirement level, an MIT group, gathered together to carry out studies in logistics, has developed a project called: SC 2020. That study (Lapide, 2005) has demonstrated that the high performance supply chains have four fundamental characteristics in common:

a) They back up, potentialize and are integral parts of the competitive businesses strategy of the company.

b) They promote a differentiated operations model to sustain competitiveness.

c) They present balanced execution between performance goals and their metrics.

d) They focus on a small set of business practices that lean on each other to cope with the operational model and its goals.

In the applied model, we tried to find out some of these characteristics, as well as the strategic alignment. Other strategic planning models can be designed along this race for better results. After highlighting the imperative necessity of integration of the supply chains, this study can undergo a more amplified analysis, especially in the area of collaborative management. Another interesting aspect, is the fact that the Russian methodology has been applied to the field of logistics for the last few years only. By that, for those cells in the contradictions matrix that do not show known solutions, new sets of principles that solve specific questions in logistics may arise.

Strategic information related to supply chain frequently feeds the decision supporting systems, as in the Delphi method for scenario analysis. This way, the importance of the contiguity between these systems (DSS), the managers’ opinion, and the performance metrics must also stimulate future studies.

CONCLUSION

Considering that the management parameters that limited the average qualitative level were mainly risks management and interface management; we observe that the common concern about the chain sustainability is valid. The necessity of good reliability and safe provisioning reinforces the importance of the strategic planning in the supply chain management. The continuous sensitivity of the chain towards information management, especially in the global operations, sends the planning efforts to the modern tendency to observe its logistic aspects in an integrated way.

As demonstrated in several studies, the application of this methodology has identified the best competitive-differential-creating opportunities within the initiatives of logistic planning. Not coincidentally, some principles suggested in this study lie in the group of the principles most frequently suggested as solution to restrictions on the producing systems, as pointed out by (Mann, 2004), and these are: 35, 2, 10, 1 and 15. The relevance of the principles to the supply chain management challenges reinforce the applicability of the Triz methodology. The set of principles presented in this study, allied to efficient logistics practices, such as: Just-in-time, just-in-sequence, milk run, cross docking, collaborative management, lean manufacturing; must constitute the adequate framework for the supply chain strategic planning.

To guide the strategic planning, Triz offers, in its contradictions matrix a variety of 853 combinations of principles for business management and 1299 combinations for the technical system, what grants it an extremely flexible character. Most of the results showed that the model values the intellectual liability, and presumes the effective utilization of intrapreneuring, as postulated by Gifford Pinchot.

Innovation and creativity, incited by the model, are important elements in effective supply chain management,. Conclusively, the effective integration of continuous and contiguous logistic processes is achieved only by the adoption of ideas like automation, segmentation, multifunctionality, etc., that grant the supply chain a performance level comparable to the efficient collaborative management in the Occident and to those of the horizontal competitive integration in the Orient. The more detailed the initial chain assessment is, the more accurate will be the model results, and this stimulates the emergence of new exploratory studies for better knowledge of its applicability.

References

ALTSHULLER, G. S. (1999). Innovation Algorithm. Worcester, Technical Innovation Center (1a ed. Russa 1969).

BOWERSOX, D.J.; CLOSS D.J.; Stank T.P. (1999). 21st Century Logistics: Making Supply Chain Integration a Reality. Oak Brook, IL: Council of Logistics Management.

BOWERSOX, D. J. (2004). Logistics yesterday, today and tomorrow. Conference-at-aclick, cscmp.

CHOPRA, S.; MEINDEL, P. (2003). Gerenciamento de cadeia de suprimentos. São Paulo: Prentice-Hall, p. 465.

CARVALHO, M. A.; BACK, N. (2001). Uso dos conceitos fundamentais da Triz e do método dos princÃpios inventivos no desenvolvimento de produtos. Florianópolis, SC. 3º CBGDP.

DORNIER, P.; ERNEST, R.; FENDER, M.; KOUVELIS, P. (2000). LogÃstica e operações globais. São Paulo, SP. Editora Atlas.

EMORY, C. AND COOPER, D. (1991), Business Research Methods, Richard D. Irwin, Homewood, IL.

GOLDRATT, E. M. (2003). Necessário sim, mas não o suficiente. São Paulo, SP. HANDFIELD R.B.; NICHOLS J.; ERNEST L.(1999). Introduction to supply chain management. New Jersey: Prentice Hall.

KERVIN, JB. (1992), Methods for Business Research, Harper Collins, New York, NY.

KIM, B. (2000). Coordinating an innovation in supply chain management. European journal of operational research, n. 123, p. 568-584.

LAMBERT, D.M., COOPER, M.C.; PAGH, J.D. (1998). “Supply chain management: implementation issues and research opportunities”, The International Journal of Logistics Management, Vol. 9 No. 2, pp. 1-19.

LAPIDE, L. (2005). The Four Habits of Highly Effetive Supply Chains. Harvard Business Review. Art. Nº P0505A.

LARSON, P. D.; GAMMELGAARD, B. (2001). Logistics in Denmark: a survey of the industry. International Journal of Logistics: Research and applications, vol. 4, nº2, pp. 191- 206.

LAI, K. H.; CHENG, T. C. E. (2003). Supply Chain Performance in Transport Logistics: an assessment by service providers. International Journal of Logistics: Research and applications, vol. 6, nº 3, pp. 151-164.

LEE, H. L. (2004). The Triple-A Supply Chain. Harvard Business review.

MANN, D. (2001). Hands-On Systematic Innovation. London: Creax.

MURPHY, J. V. (2004). Supply Chain performance management: it’s more than metrics. Global Logistics & Supply Chain Strategies. Vol. 3.

MORALES, D. K.; Geary, S. (2003). Speed Kills: Supply chain lessons from the war of Iraq. Harvard Business review.

MARTIN, B.; CLAPP, T. G.; JOINES, J. A. (2003). Integrating Ideality with the System Operator Applied to the Bullwhip effect. Triz Journal as a tutorial.

MC GINNIS, M. A.; KOHN, J. W. (2002). Logistic Strategy Revisited. Journal of Business Logistics, vol. 23, nº 2, pp. 1-17.

SLACK, N.; CHAMBERS, S.; JOHNSTON, R. (2002). Administração da Produção. 2. ed.

São Paulo: Editora Atlas.

SAVRANSKY, S. D. (2000). Engineering of Criativity – Introduction to Triz Methodology of inventive problem solving. New York: CRC. YIN, K. (1994), Case Study Research – Design and Methods, Applied Social Research

Methods Series 5, 2nd ed., Sage, Newbury Park, CA