Innovation In the Material Cost of the 8mm Camcorder Using Triz

Editor | On 07, Jun 2004

By Young-Ho Cho, Jeong-Seon Kim and Jun-Young Lee.

ccc2155@samsung.com

Samsung TRIZ Association (STA), Samsung Electronics, Co. Ltd., Suwon, South Korea.

ABSTRACT: A camcorder has come into wide use rapidly due to the increase of outdoor activities and the elevation of personal income. Therefore, camcorder manufacturers are trying to reduce material costs in order to expand the sale. In this project, TRIZ technology has been applied to achieve such a result.

This project suggests the improvement of a camcorder component named “ Pole Base†which is located in front of the Drum and guides the camcorder tape. It is consisted of 8 base components and is manufactured through 7 processes.

The suggested methods in this paper show how the number of components and processes are reduced. Three patents related to these technology changes have been submitted.

In this project, Function Analysis, Technical Contradiction and Su-Field Analysis are the main TRIZ tools that are used.

BODY

INTRODUCTION

In recent years, influenced by increase in gross income and leisure time, more people start to desire to record their valuable part of life. In order to fulfill their desire, the camcorder is good medium since it can both edit and keep images. Furthermore, the demand of the camcorder is over 10 million in the market worldwide. Due to this rapid market development and competition,, the price of camcorder keeps dropping more than 20 % annually. Therefore, manufacturers have tried to reduce the costs in order to survive in this competitive market.

This paper describes the cost reduction in video camcorder by using TRIZ.

The camcorder (VIDEO CAMERA) is composed of Camera, Circuit, Appearance, and Deck. Among the rest, the Deck mechanism functions to record and play images by operating the tape and touching the tape into Drum. This project introduces POLE BASE S, one of parts of the deck mechanism, which helps to decrease the cost by reducing the number of assemble parts in half. As Pole Base S, which is located in the entrance of Drum, guides the tape’s location precisely, Drum can execute to record and play images. The possible malfunction problem caused by decrease of precision parts, can be solve by using TRIZ (Theory of Inventive Problem Solving), widely used problem solving method, which is most readily applicable to physical domains..

Fig3 illustrates four generic steps to work out TRIZ solutions. The first step is to recognize and define the problem. And then it structures a problem into a “contradiction statement“ and derives solutions that address the problem statement from both a technical and systematic perspective. After verifying and reviewing the proposal, the project is completed with achieving the patents.

BASE S can be solved by using TRIZ. From this technology, the expected cost reduction is approximately $100,000.00 a year with patents.

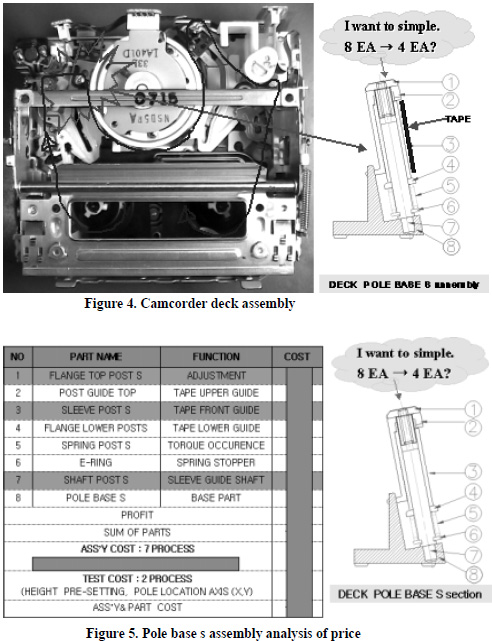

The required parts to be reduced are depicted in Figure 4 and the price of each part is shown in Figure 5. The left picture illustrated in Figure 4 is DECK assembly; whereas the right picture is Pole Base S. The Pole Base S is located in the top-left on the DECK assembly and functions to precisely guide the location of tape which is represented in circle in Figure 4. Moreover, it is currently composed of eight elements, and the goal of this project is to reduce four elements by using TRIZ method.

Figure 6 shows the assembled Pole Base S and its eight decomposed elements from the original object.

In Figure 6, the problem and goal of this project can be recognized. The aim of this project is to reduce the number of component parts from 8 to 4. Moreover, tape guide should be fully functional, even if the number of parts is reduced in half

2. Analyze step

TRIZ models, based on the theory of inventive problem solving by Altshuller, are derived from the study of patents and observed trends in the evolution of technical systems. The application of this principle includes structuring a problem into a “contradiction statementâ€. Through analyzing the problem and finding contradiction, the various solutions can be presented. The most important thing is to find contradiction and to use the appropriate TRIZ tools for analyzing.

In this project, the most appropriate solution will be defined by simulating various tools. However, only the case study has been presented in this paper.

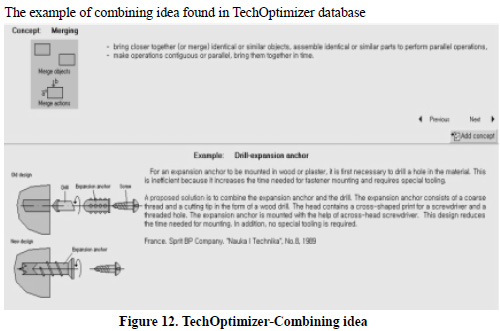

2-1-1 Function Analysis

The First step is to find essential parts through analyzing the function of each element. As Figure 7, the function can be divided into three parts in terms of the Adjustment part, the Guide part, and the Base part. Both the Adjustment and Guide part are composed of three elements; whereas the Base part has two parts.

Through analyzing each function, the functionally essential parts were founded.

The FLANGE TOP in the ADJUSTMENT PART, which performs the adjustment of the tape in the manufacture process, has a straight groove in the upper part and the lower part has a screw tap which makes rotation adjustment possible.

The Post GUIDE Top in the GUIDE PART, guiding the tape, keeps the tape location precisely through touching the upper part of the tape when the tape travels.

The POLE BASE in the BASE PART supports other 7 parts in the above.

2-1-2 Trimming

A software tool called TechOptimizer from Invention Machine Corporation has been integrated into a proprietary method for creative innovation. It is used as a model and provides assistance in understanding which aspects of a product need improvement and which of the inventive principles are most applicable. Therefore, when trimming by using TechOptimizer without the essential parts, we can conclude that the new component is needed as shown in Reformation #1.

2-2. The Analysis of the technical Contradiction.

Generic solutions at a technical level resulted in a collection of 40 inventive principles, a 39 x 39 “contradiction†matrix as well as physical resolution principles. At a system level, solutions may be derived by looking at 40 inventive principles that pertain to the overall development of engineering systems.

2-2-1. Define the Technical Contradiction

Through the reorganization of the problem, contradiction can be defined. In order to reduce the cost of pole base guiding tape, 4 parts of pole base need to be eliminated. However, it may cause the malfunction.

2-2-2. A measure Reformation using the contradiction matrix.

As the definition mentioned above, 40 suitable invention principles have been found by using a chart of contradiction matrix, which fills in 39-reformation characteristics and deterioration characteristics.

A reformation characteristic is a reduction the number of parts, which will increase the quantity of mass.

A deterioration characteristic is a decrease in functionality, which can make persistence (lasting time of working) worse. This may cause the damage in either material or system.

The figure showed below, is a contradiction matrix chart

40 invention principles can be found at the crossing point of the reformation and deterioration characteristics in the chart.

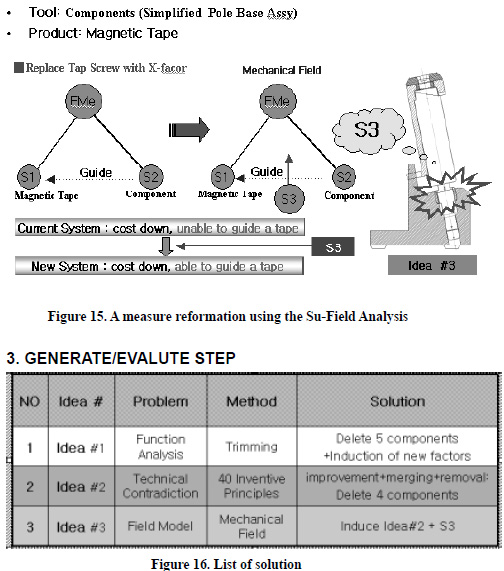

Among 40 invention principles derived by contradiction matrix, a suitable invention principle of common theories are NO 1,2,3, for reducing the number of parts of ASS’Y from 8 to 4

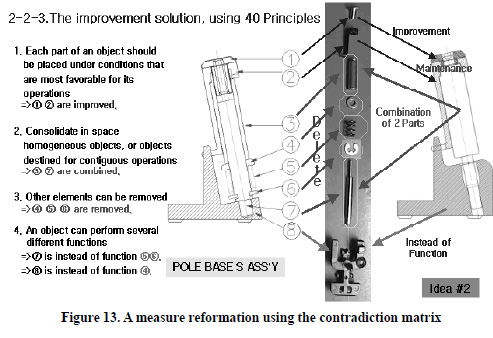

In addition, the similar idea can be found by utilizing optimum solution database.

Figure 11 shows the invention principle of No 3,5,6, and Figure 12 shows an example of utilizing optimum solution in TechOptimizer data base.

2-2-3. The improvement solution, using 40 Principles

Figure 13 shows the derivation of the solution #2 using No3, 5,6 in the Invention Principles.

Su-Field (Substance-Field) is one of TRIZ tools to analyze problems related with existing technical systems by using Su-Field Model. In order to eliminate mental momentum from a sentence in Analysis for Su-Field, solution can be derived from depicting symbols for technical problems. Figure 14 shows how to make Su-Field model as defining product and tool.

Figure 15 is the process of deriving solution from Su-Field Model. Even though the cost of materials cut down, there is still malfunction problem guiding tape; therefore, the new system should be composed through adding the third element S3( X element).

Figure 16 is the list of solution through analyzing steps so far. From the Function Analysis (2-1. Trimming), the reformation is three existing essential parts plus new component. On the other hand, through analyzing technical contradiction (2-2), the reformation is to eliminate four parts. From the analysis for Su-field, the reformation #3 derives through adding the third element in reformation #2. The generate and evaluate step is to evaluate the reformations whether they are practical solutions for application.

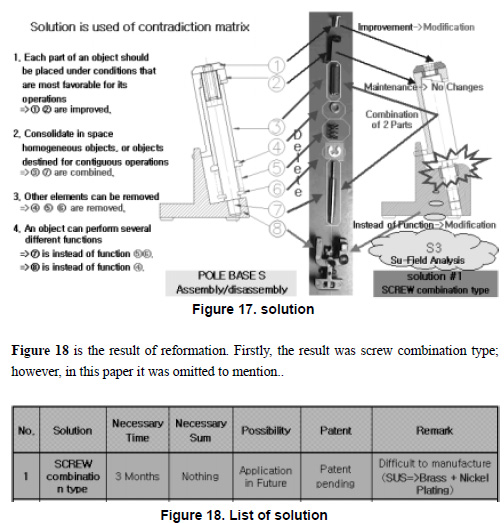

Figure 17 is the constructed solution. As shown in Figure, the solution is the combination of the reformation #2 and reformation #3; however, the reformation #1 resulted in the motive to derive the reformation #2.

4. VERIFY STEP

The last stage of TRIZ solution is to check the reformation is satisfactory and

how many patents are. Finally, the project ends with summing up the final conclusion. Unless the final settlement has been reached without friction, the extra solution can be added more.

4-1. Results for verifying

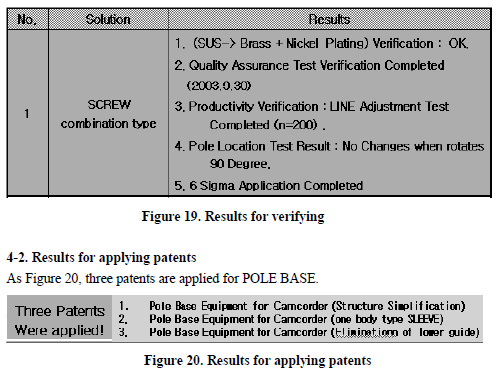

As figure 19, the result of examining production is ok if both examination of parts and the status of SET test are ok.

SUMMARY

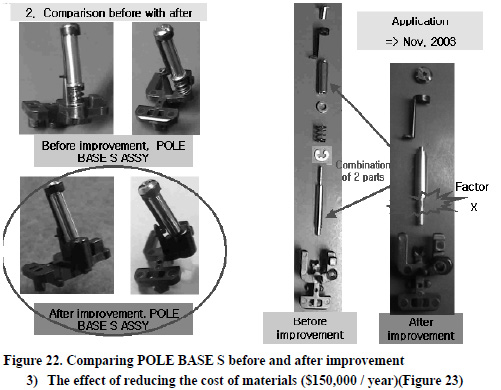

This project figured out reducing the cost of parts in DECK Mechanism related with operating Tape in widely used camcorder by using TRIZ method. As reducing 4 parts from 8 parts in POLE BASE S Assembly, one of parts in DECK Mechanism, the malfunction solved out by using TRIZ method, the cost of materials are 38 % down from $0.32 to $0.20 and the production increased 50 % more. Moreover, three patents related to POLE BASE S already have been submitted. Through Function Analysis (Trimming), Technical Contradiction, and Analysis for Su-Field in TRIZ Tool, the settlement is reformatted; furthermore, through inspecting and verifying the production and progressing mass-production with one part, the cost of materials cut down $150,000 a year.

CONCLUSION

1. Project Results

– Application: solution#1(By testing idea #2,3)

– Schedule: Nov. 2003

– Patent : 3 patents in Oct 2003

2. Project Effects

– Initial goal: $100,000

– Financial Effect: $200,000

1) Decreasing Material Cost: $150,000 (ï¿ ?â€•ï¿ ? =ï¿ 12.9 X 1,200,000 SET)

2) Improving 50% of Productivity: $15,000

(Manufacturing Process Time: 50secound → reduced to 25 second)

3) Inferiority rates 70%: $35,000 (90 Degree Rotation Inferiorty: 15% → 5%)

3. Impression and Plan

– Impression : TRIZ gave me the logical thought for invention and several solutions

from tool and database.

– Plan : I want to make marvelous and financially successful inventions by using TRIZ.