The Development Of The Cotton Gin, 1796 To 1844

Editor | On 02, Oct 2003

By: William Fowlkes, Ph.D.

The initial invention

Eli Whitney’s invention of the cotton gin (short for cotton engine), a machine that could efficiently remove cotton fiber from its seeds, has been hailed as a revolutionary invention that helped fuel the early American economy. Many have assumed that Whitney’s gin sprang from his inventive mind, as the result of the need to mechanize the difficult task of separation, after observing the slaves manually separating fiber from seed.1 In fact, the development of the cotton gin and its subsequent refinements followed a predictable sequence of product evolution. Here we will critically examine this seminal invention and its progeny to illustrate the Triz principles of technology evolution.

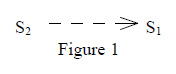

As is usually the case in technology development, there were precursors to Whitney’s invention. More than two millennia earlier in India the churka or roller gin came into existence. This device consisted of two wooden cylinders held closely together by a frame and rotated by a crank. The rollers were fluted by a series of longitudinal grooves and would separate loosely bound fiber from its seed by squeezing the cotton boll as it passed between them. Sea Island cotton, a long staple variety, was ginned in the 18th century using such a device. The limitations of the churka created an administrative conflict: Sea Island cotton could not be grown successfully inland. The more robust short staple, Inland cotton, could be widely cultivated but its fibers resisted separation when passed through the roller gin. Thus, the technical problem could be defined as an inadequate or weak interaction between the rollers, failing to produce a useful product, as diagrammed in Figure 1, where S2 is the roller and S1 is the cotton fiber.

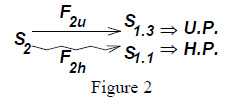

The method chosen by Whitney to solve the initial technical conflict was to modify the tool to increase the interaction. This could be easily done by the addition of bent wire teeth, whose shape and function were already in use at the time in wool-carding devices. Of course, this increased the interaction with both the fiber as well as with the seed, which was bound tightly to the fiber. Figure 2 illustrates the technical conflict2 created by the interaction of the teeth S2 with both the seed S1.1 and the fiber S1.3.

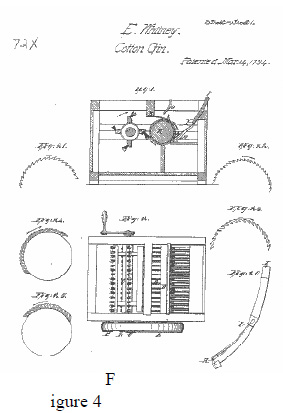

The critical invention by Whitney (Figure 4) was to pass the teeth through a slotted metal breastwork with openings wide enough to pass the teeth but narrow enough to hold back the seed, thus effecting the separation. The breastwork eliminated the harmful interaction by applying the principle: Counteract the harmful interaction by the opposing field Fx, shown in Figure 3.

Thus, the cotton boll is cleaned by two opposing mechanical fields. The first, from rows of individual teeth, draws the fiber out. The second, from the slotted breastwork, holds the seed back. This is the fundamental invention Eli Whitney patented in 1796. His patent also included a second rotating cylinder, covered with hog bristle brushes that could clear the cotton fiber from the teeth and blow the lint down to a collection box.

Solving subsequent problems

Triz teaches us that all engineering systems evolve toward ideality. But most engineering systems, when first developed, are far from ideal. Thus, there began a period of rapid evolution as the conflicts and inadequacies of the initial concept were resolved. In the past this has been a fitful process as inventors stumble upon solutions to known problems and new problems are gradually revealed, calling for further improvement. Knowledge of the principles of Triz allows current and future technologist to proactively seek out improvements and approach ideality much faster than ever before.

Some of the problems that were immediately evident even to Whitney included the following. A practical problem resulted from the initial design. The bent-wire teeth would work free from the cylinder, creating a safety hazard as well as requiring frequent repair. Whitney discovered that it was important to separate or disconnect the fiber pulled through the breastwork by the teeth from the fiber and seed held back or else the seed roll would become so matted that it will “obstruct and bend the teeth.â€3 Another issue involving the seed roll was the removal of the seeds. Initially, the hopper and breastwork would have to be opened up regularly and cleared manually, reducing the productivity of the machine. As already mentioned, the fiber must be removed from the wire teeth prior to the teeth passing through the breastwork for the second time. The addition of a second brush roller is proof that the teeth covered roller was not ideal by itself.

One major Triz principle in the evolution of technology is simplification of a system by the folding or merging of subsystems. Viewed in this way, we can see that the myriad of individual wire teeth studding the cylinder represents much too complex a system. Thus, one of the first notable improvements in the cotton gin, achieved by H. Ogden Holmes, was to replace the spiked cylinder with saw teeth cut into a set of concentric disks mounted on a single shaft. Each circular saw, spaced about one inch apart, would pass through one slot of the breastwork. Holmes also used flat ribs in the breastwork angled such that the seeds would be cast off as they were separated from the fiber. Holmes received his patent in 1796, just two years after Whitney’s first patent.

Another Triz principle of technology evolution is subsystems appear in opposition to each other in technical systems, the classic example is an eraser attached to the end of a pencil. This is a very powerful principle that is commonly seen. In the case of the saw gins, it did not take long until the utility of having at least one tooth reversed in each circular saw was recognized. The function of the opposing tooth was to clear the slots of any matted fibers by reversing the direction of the saw disks.

Later developments in ginning

Many other principles were soon satisfied. In 1805 combination gin-spinners appeared, demonstrating combining of a system with its supersystem. In 1834 a double cylinder gin was patented thus creating a bi-system. In 1837 an adjustable seed board, which could regulate the amount of seed cotton pulled in by the gin, was developed thus increasing the dynamism of the system. In 1858 a poly-system consisting of a ginning cylinder and clearing brush followed by a second, faster rotating, ginning cylinder and clearing brush produced an improved product commanding a higher price.

After the Civil War, the technology evolution proceeded forward with the focus no longer being on the basic ginning mechanism but on combining the gin with auxiliary functions, a folding of systems in the super-system into a single integrated device. Combination feeder, gin stand and condensers with dyers became common. Often the system was placed in close proximity to compressors and balers so that the lint could be blown directly into the finishing operation. Elaborate lint handling systems using belts and air driven flues appeared by the end of the nineteenth century.

The latest improvement in ginning is the application of a microprocessor to automatically control the rate at which cotton is ginned. This is anticipated by the Triz principle the system will replace manual intervention by automatic adjustment. The controller senses how much torque is required to drive the saw blades. Too much indicates that the feed is too fast which could lead to expensive clogging, too little and the gin is operating inefficiently. Thus, we see that today’s cotton gin is working very close to its theoretical maximum ideality or optimized design.