Case Study Based on TRIZ: Speedy Cutting off Valve

Editor | On 12, Jul 2004

By: Cao Guozhong, Tan Runhua, Zhang Ruihong

Institute of Design for Innovation, Hebei University of Technology

Tianjin, 300130, P.R.China

Tel: +86-022-2656-4871

E-mail: cgzghx@163.com

Abstract: After investigating the operation of the TRT system of the blast furnace and analyzing the structure of the speedy cutting off valve, the functions of the speedy cutting off valve are decomposed by using the reverse fishbone diagram and function analysis. From the point of view of the system function, the problems of the speedy cutting off valve are described. After the new principle solution is confirmed by effects and the function structure is improved by trimming, the solution to the problems existing in the speedy cutting off valve is put forward.

1. Introduction

Top Gas Pressure Recovery Turbine (TRT) is a device of very valuable energy recovery and is generally accepted by the Iron & Steel companies over the world. The Blast Furnace gas from top pressure furnace will be depressurized by turbine to produce electrical energy by means of a generator. By using this system, the power output of top gas pressure recovery turbine can cover about 30% of electricity necessary for all equipment attached to the blast furnace including air blowers. This kind of two times energy recovery method does not consume the fuel, has no middle transportation of raw material, does not produce pollution in the movement process, and has low cost of generating electricity. The method has remarkable result in energy recovery and has very important realistic meaning for the metallurgy production to lower energy consumption of iron process (Wu, 1994). Speedy cutting off valve is pivotal equipment in TRT and is used for urgent cutting off, which cuts the gas in the pipe connected with the valve rapidly when something wrong happens in order to protect the whole system. After investigating the operation of the TRT system of the blast furnace and analyzing the structure of the speedy cutting off valve, the problems existing in the speedy cutting off valve are described and the process of solving problem is put forward.

2. TRT System and Speedy Cutting Off Valve

The technology process of TRT system is shown in Fig.1. After the top pressure gas sent out from the blast furnace is handled by cleaning facility and special bag filter, it is sent to the top pressure recovery turbine and decompression valve set. The top pressure gas shifts to the TRT import tube in front of the decompression valve set, passes through the hydraulic-operated closed insert plate valve, the speedy cutting off valve, the adjusting valve and variable stator blades, lastly, comes into turbine to work by inflating. Turbine drives generator, and electricity is generated. The inflated top pressure gas is firstly dehydrated by dehydrator, then is sent to gas pipeline after the decompression valve set. Thus the TRT and the decompression valve set are parallel relation. There is a bypass valve which locates after the inlet insert plate valve and before the outlet insert valve. When the TRT urgently stops, the bypass valve is used for the steady transition between the TRT and decompression valve set in order to insure the furnace-top pressure does not produce the big motion. The low pressure gas coming out from the TRT and decompression valve set is sent to the gas cabinet or users (Zhang, 1994). Basic process of valve system in TRT is shown in Fig.2 (Xu, 1998).

Speedy cutting off valve is a double-eccentric butterfly valve as shown in Fig.3. It is included in the TRT, which cuts the gas in the pipe connected with the valve rapidly when something wrong is happen in order to protect the whole system. The opening and closing actions of the valve, including the slow opening, slow shutting, quick shutting and moving about movements, are controlled by a hydraulic system. According to the actual circumstance of production, there are some problems in the speedy cutting off valve of TRT system (Xu, 1998):

1. The hydraulic control system is mainly consisted by hydraulic pumping station, oil box, accumulator, and control station, and the whole system transports oil to six points (insert plate valve used for entrance and exit of TRT, speedy cutting off valve, timing valve, tunable turbine blade, and bypass valve). Because there is much dust content in the blast furnace gas and the oil in hydraulic system of insert plate valve directly gets in touch with the dust in the opening or closing process, the request for the clean degree of oil can hardly be contented.

2. There are some problems of instruments in hydraulic system, such as the poor dependability of the pressure control switch and press-different announciator, and the unsteady performance and quality of the servovalve and servoamplifier.

3. Because the operation environment is abominable and the speedy cutting off valve acts unfrequently, its dependability is lower.

4. In the finial stage of urgent close of the speedy cutting off valve, the elasticity minishes along with the letting up deformation of the dynamical spring. But the hydraulic system can’t provide with the force that has the same direction with the elasticity, therefore, the momentum is lack and valve can’t close completely.

5. When TRT system is normal to work, the speedy cutting off valve is placed in open status. Thereby, the hydraulic system must keep on working and the large quantity electric power is consumed.

The key technique request for the speedy cutting off valve is that the quick shutting time must be controlled within 0.5 second (The metrical starting point is when the support axis of the speedy cutting off valve begins to turn, and the metrical terminal point is about 10 degree before the valve mouth). Therefore, the actions of the speedy cutting off valve must be rapid, accurate and reliable. According to the important function of the speedy cutting off valve in TRT and the problems existing in hydraulic system mentioned above, the improvement of the hydraulic drive system is needed.

3. Function Analysis for Speedy Cutting Off Valve

It is necessary for the problem to be described precisely and detailedly and for the problem model to be established. The main purpose of a technique system is to satisfy one or several function. The problem or design requisition can be described by function. The technique system can usually realize many functions. Some is useful and others are useless or harmful. The chief task for the designer is to confirm the function units, analyze the correlation among the function units and establish the function model of system. In order to realize the demand mentioned above, function analysis is adopted.

A fishbone diagram is a kind of diagram to show the assembly sequence of components (Ishii et al., 1995). A reverse fishbone diagram is the reverse application of a fishbone diagram, which is used for analyzing the recyclability of products. Tan et al. (2001) apply the tool to determine the support functions of a product. Here, the method (Tan et al., 2001) is modified to be suitable for determining the function elements and setting up the function model for an existing product.

Function model graphically creates the products, components, and supersystems of the engineering system and the interactions between them, and analyze the interactions. According to the relationship between the current and the required performance level each function is defined as either a Useful action or a Harmful action. The useful actions include the normal, insufficient and excessive actions. The insufficient, excessive and harmful actions are all mini-problems in an existing product and the reasons for redesign or improvement.

The process of functional modeling can determine insufficient, excessive and harmful functions, which are mini -problems of the system. After that the inventive principles, separation heuristics, standard solution in TRIZ (Tan, 2002) can be used to solve them. The solutions will push the process of the product evolution.

The process of functional modeling of the speedy cutting off valve is shown as following:

Step 1: Determine the supersystems with the input or output relations to the speedy cutting off valve: the basic bracket, the gas pipe, the dust and the power supply;

Step 2: Determine the artificial object: the blast furnace gas;

Step 3: Disassemble the module one by one from the existing product and determine the functional elements;

Step 4: Establish the reverse fishbone diagram for the speedy cutting off valve as shown in Fig.4;

Step 5: Determine all connecting actions and the types and develop the functional model as shown in Fig.5 (Invention Machine, TechOptimizer 3.5);

From the point of view of system function, the Fig.5 shows the problems of the speedy cutting off valve in TRT, such as the harmful actions: the motor and the hydraulic control box consuming massive electricity supply and the dust polluting the oil, and the insufficient actions: the filter and the pipeline counteracting the fluid of oil and the dynamical spring driving the piston deficiently. Perfecting the above function is the starting point for the latter improving design. If the force with the same direction to the elasticity of spring can be provided, the problem that the dynamical spring drives the piston deficiently in the end of process of speedy cutting off will be solved and the execution element can still adopt dynamical spring. The method is simple and reliable. According to the function analysis the hydraulic drive system is removed and new drive device is adopted. It is required for the new drive device to realize the slow opening, slow shutting, quick shutting and moving about movements and to generate the force with the same direction to the dynamical spring in order to assure the valve of complete closure.

5. Effects

TRIZ, based on a systematic view of technological world, provides techniques and tools, which help designers to create a new design idea and avoid numerous trails and errors during a problem solving process. Effect Knowledge Base is probably the most easy to use tool in TRIZ. Very early in his research, Altshuller recognized that given a difficult problem, the ideality and ease of implementation of a particular solution could be substantially increased by utilizing various physical, chemical and geometric effects, thus a large vast of database has been developed[7] . Altshuller placed strong emphasis on the collation and categorisation of physical, chemical and mathematical effects in mankind’s sum knowledge base. By categorising such effects in terms of their function, he generated the idea for a very powerful database. The database has perhaps been most potently implemented in the TechOptimizer software — which now contains close to 6000 known effects and examples, and continues to grow (Bohuslav et al., 1999).

Classification by function means that if we have a problem like the one in the speedy cutting off valve where we wish to improve the problematic action ‘hydraulic drive system’, we are able to do so quickly by examining functions related to the action ‘move’. For example looking up the function ‘move solid substance’ in the Effects database, we are able to very quickly establish which effects may be relevant to the specific problem at hand. The drive function can be realized by using light, electricity, magnetism, thermal, gas, sound Effects etc, as shown in Table 1.

In order to get a simpler, cost-effective system and convenient operation, the effect ‘magnetic field of solenoid’ is selected and the hydraulic drive system is substituted by the electromagnetic drive system. While the electric current passes the solenoid, the magnetic field is generated inside the solenoid. The intensity and direction of magnetic field depends on the intensity and direction of the voltage or current. Changing the intensity and direction of magnetic field, the ferromagnet can move in different directions and with different speed.

6. Function Improvement

The system can be improved by combining the effect ‘Magnetic field of solenoid’ with the function model of the speedy cutting off valve. Trimming is the method of improving engineering systems by eliminating the problematic or costly system components and redistributing the component of useful functions. As a result of the trimming process, you can have a trimmed or more ideal model and a list of new problems (Invention Machine, TechOptimizer 3.5). If the problems are solved, the engineering system will be a simpler, cost-effective system, which performs as well as the original. Trimming inclines the product or technology towards the Ideal Final Result (IFR) (Tan, 2002).

The improved function model of the speedy cutting off valve is shown in Fig.6. In the improved drive system the hydraulic devices are removed completely. Controlled the intensity and direction of voltage or current in solenoid by electricity cabinet, there will be different magnetic field in the solenoid and the connecting rod will move to opposed directions with different velocity. The system can realize all motions, such as the slow opening, slow shutting, quick shutting and moving about movements, as well as the buffering and the complete closure of valve.

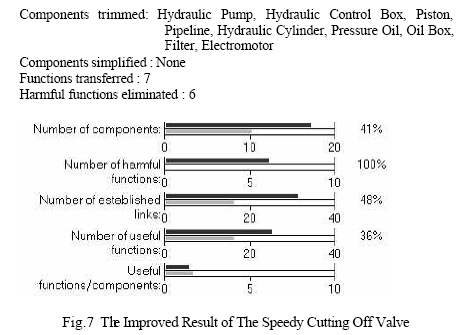

The improved result of the speedy cutting off valve is shown in Fig.7. Comparing the improved system with the original system, 33% of elements and 43% of interactions between elements are decreased, the harmful actions are eliminated completely, the system structure is simplified and the cost is reduced. From the point of view of system perform the negative effects aroused by the hydraulic system, such as the pollution of oil, the flow resistance of oil, the unreliability of hydraulic meter and deficiency force of spring, etc, is removed by substituting the hydraulic drive system with electromagnetic drive system. Every movement of the speedy cutting off valve can be implemented, and the operation is more simple and the system perform is increased.

7. Conclusion

1. A systematization method for determination of principle solution that contents the required function in conceptual design is put forward.

2. The reverse fishbone diagram, function analysis (TRIZ analytical tool) and effect (TRIZ knowledge base tool) are combined to determine the problems and the relative principle solutions.

3. The paper has demonstrated how those tools and techniques have been used to create a solution to a real-life speedy cutting off valve redesign case. The application process proves that the systematization method is feasible.

Acknowledgement

The authors are grateful to the Chinese National Natural Science Foundation (No. 50375045) for funding this work.

References:

Yaping Wu, 1994, “Actuality analysis and potentiality exploration of WISCO No.3 blast furnace”, WISCO Technology, Vol.3, 58-64.

Weimin Xu, 1998, “Several attentive problems in the process of expanding of national TRT”, Ironmaking, Vol.17 No.1, 31-33.

Lianrui Zhang, 1994, “On establishment and operation of top pressure recovery turbine of blast furnace No.1 in Tangshan Iron & Steel Co.”, Metallurgy Energy, Vol.13 No.5, 52-55.

Ishii K., and Kmenta S., 1995, “Introduction to design for assembly, Design for Manufacturability: Product Definition”, Stanford Bookstore.

Runhua Tan, Guolin Duan, Yanhong Lian, 2001, “Quality function deployment in bottom-up process for design reuse”, Chinese Journal of Mechanical engineering, Vol.14 No.4, 381-384.

Runhua Tan, 2002,”Innovation Design—TRIZ: Theory of Innovative Problem Solving”, Beijing: Chinese Mechanic Press.

Kai Yang, and Hongwei Zhang, 2000, ” A Comparison of TRIZ and Axiomatic Design”, TRIZ Journal, https://the-trizjournal.com/.

Invention Machine Corporation. TechOptimizer Professional Edition V3.5, 2000.

Bohuslav, B., Darrell, M., and Pavel, J., 1999, “Case Studies In TRIZ: A Novel Heat Exchanger”, TRIZ Journal, https://the-trizjournal.com/.