Some Aspect of TRIZ Applications in Steel Making Process

Editor | On 21, Oct 2005

By: J.E. Cho

Some Aspect of TRIZ Applications in Steel Making Process.

2005. 7.2

J.E. Cho Ph.D

Technical Research Lab.

POSCO

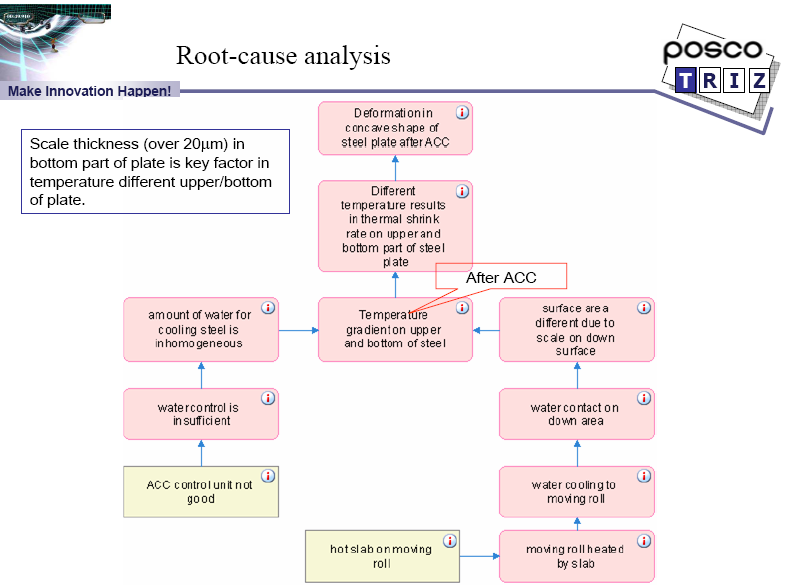

Steel plate (thickness : 40-60mm) deformed (above 5 mm) due to temperature difference between upper and bottom area of plate after ACC process.

Problem description (I)

What we want

Temperature diff. within 25°C between upper and bottom area of plate

Current state

Temperature difference: 50°C

How to reduce temperature gradient between upper and bottom area of steel plate ??

Fact : 1) Temperature diff.(50 C) in upper/bottom after ACC ->Deformed plate

2) No significant temperature diff. before ACC process. (less than 30 C )

3) Thicker Scale formed -> More temperature decline than non-scale (thinner) formed area in ACC

Assumption :

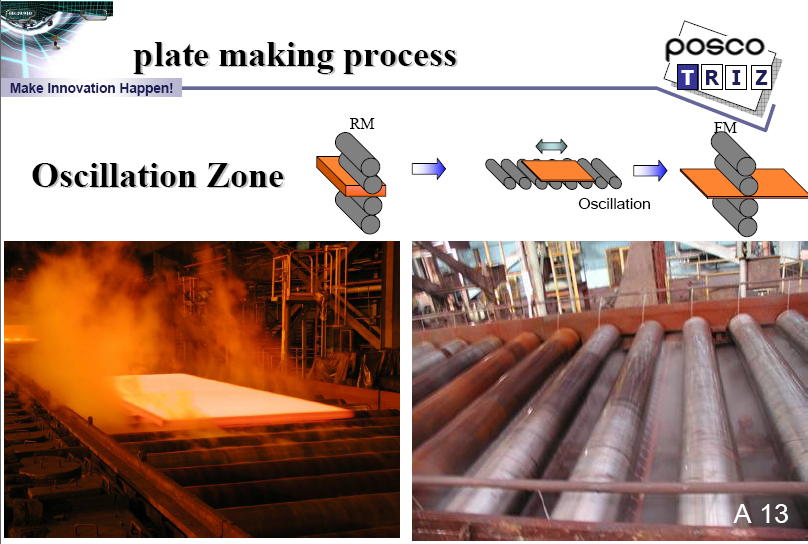

1) Main factor of scale growth is delay time between RM and FM on roller table due to contact cooling water

2) The more delay on roller table between RM and FM, the bigger asymmetry in scale growth by cooling water

Scale thickness difference between top and bottom area of plate

Problem description (II)

What we want

Prevent scale formation in plate surface

Current state

Scale formed

How to prevent scale formation in plate surface?

Restrictions of Project

1) Roll temperature must be maintained less than 100C° all the time

2) The method for internal cooling of roll can not be applied due to high cost

Algorithm for Inventive Problem Solving (ARIZ)

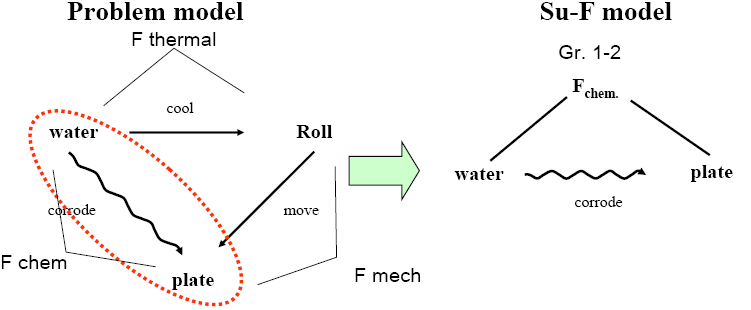

Example 1: Water and scale

Roll move plate (main useful function)

water cool roll ( useful)

water corrode plate (harmful)

Initial situation/pre-problem statement:

When roll moves hot plate , plate heat the roll. Thus cooling roll by water.

But water and vapor also corrode plate and make bad scale on plate surfac Scale should be removed.

Algorithm for Inventive Problem Solving PART 1.1

1.1. Write down conditions of a mini-problem (without special terms) as follows:

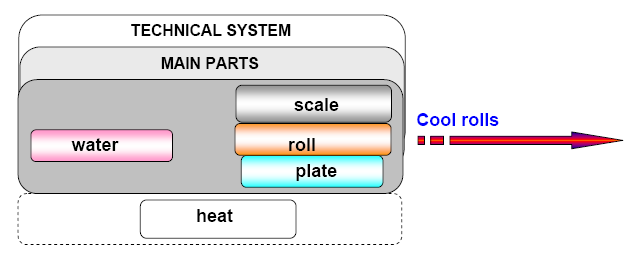

The technical system to move plate includes roll, plate, water, vapor, heat and scale.

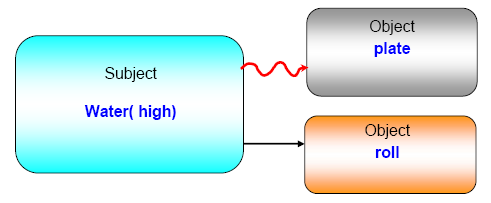

TC1 : If amount of water is high, rolls are cooled enough but plate is corroded a lot by water

TC2 : If amount of water is low, plate is not corrode seriously but rolls are not cooled enough

Under minimal changes in the system it is required: to cool roll And prevent scale formation from plate without reducing of cooling rate of roll.

Algorithm for Inventive Problem Solving PART 1.2

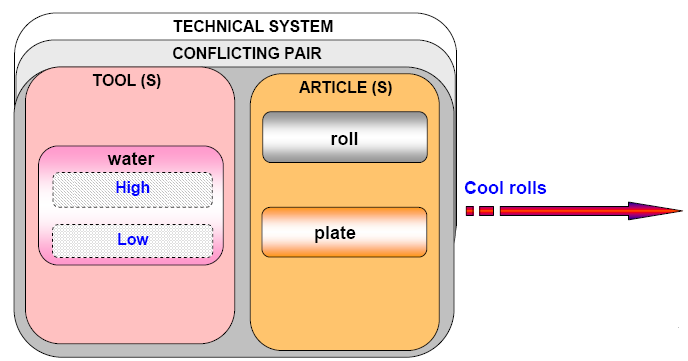

1.2. Selection of the conflicting pair:

Roll move plate

Water cool roll

Water corrode plate

Algorithm for Inventive Problem Solving PART 1.3

1.3. Formulate Technical Contractions TC 1 and TC 2 using a conflicting pair and create their diagrams using the Diagrams of Typical Conflicts in Table 1.

A. Technical contradiction1 – TC 1: (identify)

TC 1: If amount of water is high, rolls are cooled enough but plate is corroded a lot by water

B. Select/create diagram of TC 1 using Table 1

Algorithm for Inventive Problem Solving PART 1.3

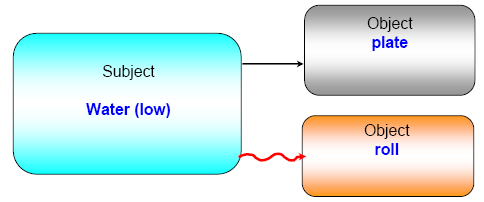

C. Technical contradiction 2 – TC 2: (identify)

TC 2: If amount of water is low, plate is not corrode seriously but rolls are not cooled enough

D. Select/create diagram of TC 2 using Table 1

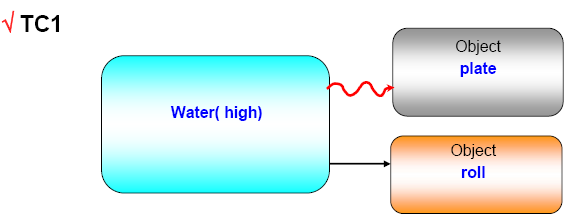

Algorithm for Inventive Problem Solving PART 1.4

1.4. Select one conflict diagram from the two technical contradictions, (TC1 and TC2), that provides the best accomplishment of the main production process (the main function of the technical system specified in conditions of the problem).

The main function of the system is to move plate, then roll cooling rate is important to operate roll system so, TC1 should be selected:

TC 1: If amount of water is high, rolls are cooled enough but plate is corroded a lot by water

Algorithm for Inventive Problem Solving PART 1.5

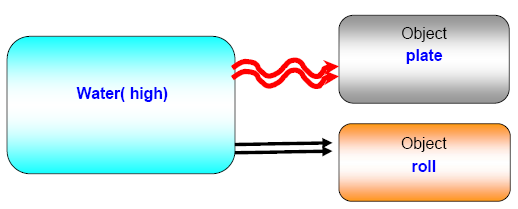

1.5. Reinforce (intensify) a conflict, specifying a limit state (action) of elements (parts).

If amount of water is extremely high, rolls are cooled very enough but plate is corroded a lot by water

Algorithm for Inventive Problem Solving PART 1.6

1.6. Write down a specified problem model:

A. Conflicting pair : Water and plate

B. Reinforced (intensified) formulation of a conflict

B. If amount of water is extremely high, rolls are cooled very enough but plate is corroded a lot by water

C. It is required to find x-element, which solves a conflict of the selected TC

C. It is required to find x-element, which preserves very enough cooling rate of roll and would not create high corrosion rate of plate by extremely high amount of water

Algorithm for Inventive Problem Solving – Part 1.4

1.7. Check possibility of using of the System of Standards to solve the problem model.

If amount of water is extremely high, rolls are cooled very enough but plate is corroded a lot by water

It is required to find x-element, which preserves very enough cooling rate of roll and would not create high corrosion rate of plate by extremely high amount of water

Problem description (III)

What we want

How to get uniform and low thickness of scale on the bottom of steel plate (less than 20 μm)

Current state

Scale formed thick and not uniformly (Scale thickness difference: 7-40 μm)

How to do it (AC)

How to make scale thickness uniformly in bottom area of plate during roller table

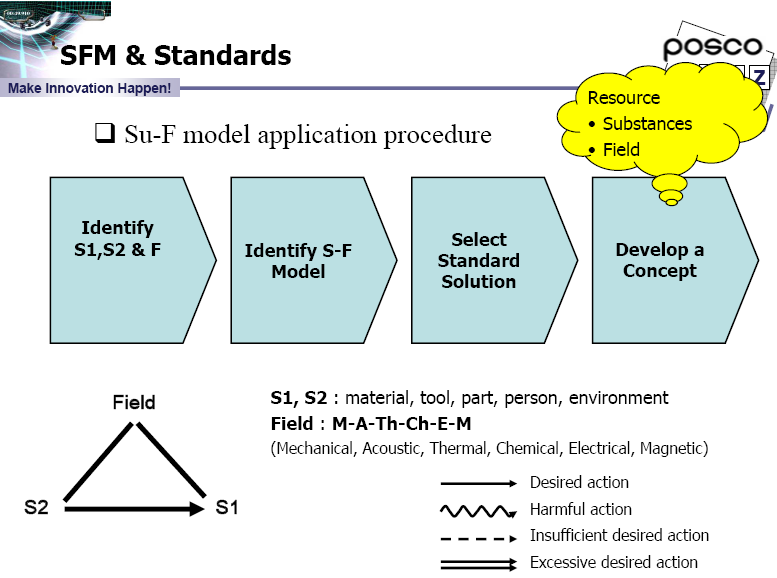

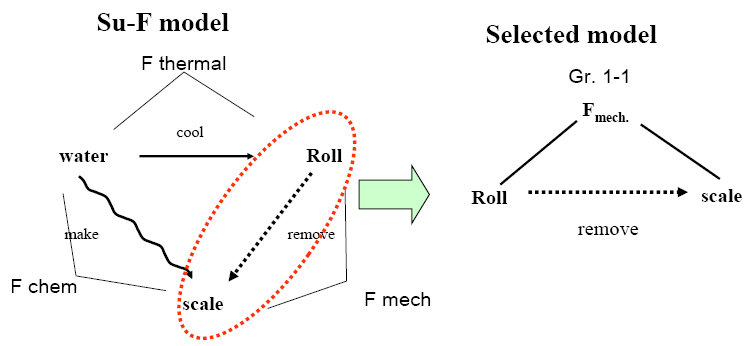

Function Analysis

Roll move plate (main function I)

water cool roll (main function II)

water make scale (harmful)

plate hold scale (harmful)

IFR

Scale should be removed all by itself.

Mini-problem

It is necessary to easy remove scale from plate by introducing minimal changes in the system.