A Typical Example of Innovative Design Based on the TRIZ

Editor | On 08, Jul 2004

By: Feng Yuan, T.Y. Wang

Feng Yuan

Tianjin University

Tianjin 300072,China

Yuanfeng509@sohu.com

T.Y. Wang

Tianjin University

Tianjin 300072,China

tywang@tdme.tju.edu.cn

Abstract

This article introduced a concept design of a machine used to bottle paint. Some technical contradictions occurred in the design, which made it difficult to find a solution except compromise. When TRIZ was used in the design, things seemed to get easy. A surprised and almost perfect solution was found, and finally it was put into practice smoothly.

Introduction

“TRIZ” is the acronym for “Theory of Inventive Problem Solving” in Russian. TRIZ was developed by Genrich Altshuller and his colleagues in the former USSR starting in 1946, and is now being developed and practiced throughout the world. Many companies are using TRIZ on many levels to solve real, practical everyday problems and to develop strategies for the future of technology.

TRIZ was introduced into China only few years ago; people in China are still very strange to it. But it has aroused some scholars’ great interests. They began to study and develop TRIZ, especially they are working hard to make TRIZ universally known and used in China.

The application of TRIZ

Pouring paint into ten-interlinked plastic bottles is a technical requirement put forward by a company according to the market. Based on this requirement, a machine should be designed to finish the working procedure with plastic containers going forward in the direction as shown in figure 1. Plastic bottles are emplaced into nylon pedestals, and pedestals are fixed on a conveyer belt that is powered by a step motor.

The machine is equipped with ten tubing pumps used to pour ten different paints into ten-interlinked bottles. When bottles are filled with paints, their lids will be turned over and shut automatically by some mechanism of the machine. All these motions are controlled by PLC.

Among the above-mentioned functions, lids’ turning and shutting are the most complicated motions. So their designs are the key in the conceptual design of the machine. If these motions are divided and implemented respectively by some executors (air cylinders), the mechanism of machine would be very complicated. So how to solve this problem is the first step to the design. We decide to resort to the TRIZ.

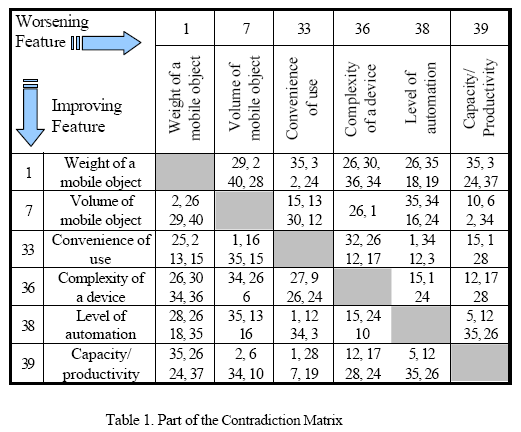

A basic principle of TRIZ is that a technical problem is defined by contradictions. That is, if there are no contradictions, there are no problems. It’s easy to see the technical contradiction in this machine design: we want to improve the level of automation, but it led to the complication of mechanism. So the improving feature should be ‘Level of automation’ (row 38), while worsening feature be ‘Complexity of a device’ (column 36). We selected corresponding row and column from the Contradiction Matrix (see table 1), and then we got “15,24,10 â€principles in the cell at the intersection. These numbers refer

to the principles that have the highest probability of resolving our contradiction.

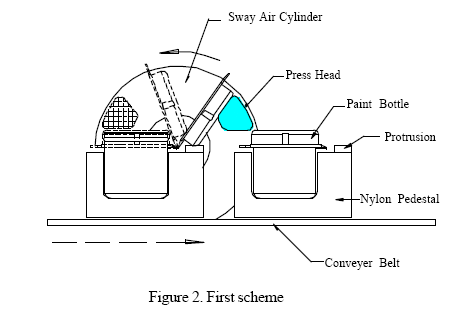

We read each recommended principles, consider the examples, construct analogies between the examples and our situation, then we find principle 10-Preliminary action is the most suitable one. It reminds us to pre-arrange objects such that they can come into action from the most convenient place and without losing time for their delivery. If we pre-arranged bottle lids at convenient places instead of their natural positions, it would be very easy to turn the lids. Guided by this principle, we design a little protrusion on every pedestal. When plastic bottles are emplaced into a nylon pedestal, their lids would lift some angles under the constraint of the protrusion. Then we got our first scheme like figure 2.

As can be seen in the figure 2, only a simple press head that powered by a sway air cylinder is needed in this situation; lids’ turning and shutting can be accomplished in one move. Till now, the contradiction has been solved satisfactorily.

After the careful analysis, we find this scheme has obvious shortcomings. Limited by the geometry space, the press head shape is not reasonable; its rigidity is not enough either. If we want to improve the press head shape and rigidity, we must have enough space. A new technical contradiction appears.

Similarly, we first confirm that improving feature is ‘convenience of use ’ (33) and worsening feature is ‘volume of mobile object’ (7). From the contradiction matrix, we got “1, 15, 16, 35†principles. These principles are only the “most probable†ones, not every principle can give us definite solution, and we have to try each one until we find the best answer. Finally, we believe that principle 1. Segmentation is the most valuable one to solve present problem. The method ‘Divide an object into independent parts’ enlightens us to divide the function of press head into two independent ones, that means the lids’ turning and shutting are implemented by different parts instead of the press head itself. So we design a baffle to turn lids by the aid of the conveyer belt power, design a press roll to press lids by the same power. (See figure 3).

Now we have solved another technical contradiction. In second scheme, no specialized power is needed, and machine can carry out lids’ turning and shutting without any intermission. The mechanism is very simple, reliable; and it’s very easy to realize the auto control. With the guidance of the TRIZ, we have solved the whole problem: that is, to lead to a breakthrough solution instead of a trade-off.

Conclusion

TRIZ is a heuristic innovative design method; it’s very helpful in the conceptual design of a product. TRIZ practitioners can follow Contradiction Matrix to select which principles to apply to a specific problem. By considering the examples, constructing analogies between the examples and specific situation, as likely as not practitioners get access to breakthrough solutions.

We expect TRIZ has as many examples as possible . By these concrete and vivid successful examples, inspiration spark would be ignited easily. So we recommend this article to be one of the examples of TRIZ, and wish people to get some elicitation from it.

References:

[1] G. Altshuller, Forty Principles TRIZ Keys to Technical Innovation, Technical Innovation Center, Inc., 1997.

[2] . Ellen Domb, Ph.D. Contradictions: Air Bag Applications. The TRIZ Journal, July, 1997.

[3] J. Terninko, A. Zusman, B. Zlotin, STEP-by-STEP TRIZ: Creating Innovative Solution Concepts, St. Lucie Press, 1996.

About The Authors

Feng Yuan is currently a Ph.D. candidate in the College of Mechanical Engineering, Tianjin University, China. His research interests include innovative design of mechanical product, high-speed machining technology. He holds 2 patents. His email address is Yuanfeng509@sohu.com

T.Y. Wang is a professor in the College of Mechanical Engineering, Tianjin University, China. His research includes modern design methodologies, and intellectual diagnosis of mechanical failure. He has published over 60 papers. He holds a doctor of philosophy degree in Mechanical Engineering from Tianjin University. His email address is tywang@tdme.tju.edu.cn.