TRIZ Journal October 2000 Issue PDF

Editor | On 25, Oct 2000

1. Getting TRIZ Accepted in a Very Busy World

By: Jack Hipple

2. On the History of Separation Principles

By: Y. B. Karasik

3. Intuitive Design Method (IDM), A New Approach on Design Methods Integration

By: Denis CAVALLUCCI, Philippe LUTZ

4. Containment ring problem (Impeller burst) IWB Case study

By: Alla Zusman

5. Enhancing Robust Design with the Aid of TRIZ and Axiomatic Design (Part I)

By: Matthew Hu, Kai Yang, Shin Taguchi

6. The Conceptual Design Of A Fast Clasping Mechanism Based On Function Means Tree AndTRIZ

By: Tan Runhua

7. The “Sabotage Model” or how to find the cause to difficult and mysterious problems: The case of Recovery Boiler compound tube corrosion

By: Pentti Soderlin

Jack Hipple

Senior Consultant

Idea Connections

Urbana, IL

217-344-2571

217-344-2572(FAX)

jwh@innovating.com

TRIZ and its many embodiments in various consulting and software programs is a powerful addition to set of problem solving tools available to engineers, human resource managers, organizational development personnel, and strategic planners. However, as many suppliers of software, training, and consulting services have found, it is not necessarily easy to gain acceptance of a new tool no matter how good we in the TRIZ community think it is. This presentation will review the barriers to acceptance and suggestions on ways to overcome them.

As everyone who uses the TRIZ methodology, its software embodiments, and its various enhancements knows, it is a powerful tool for problem analysis and solution. Many TRIZ problem solvers have seen TRIZ techniques solve problems unsolvable by other methods and teams of people working for long periods of time. If this is true, why has TRIZ not taken off in the same way as other widely accepted industrial problem solving processes and tools? Or is it that we are simply impatient and its adoption is on its normal course?

This author believes the experiences in the market place would suggest that a combination of these two issues is responsible. If we do not take the time to understand and these issues, the TRIZ community will continue to be frustrated in its attempts to commercialize a problem solving process which is known to be an extremely valuable tool. Though the comments in this paper are generic in nature and this author believes they apply to any form of the TRIZ methodology, the experiences related in this paper have come primarily from running 3-day problem solving sessions with Ideation TRIZ and the use of the Innovation Workbench® software.

These are the issues and factors that must be considered in the process of getting TRIZ accepted by its potential customers:

1. TRIZ must be considered as a new technology. In the sense that any new technology presents a new way of solving problems, it is no less difficult to get people to accept TRIZ than it was the copier machine, desktop computers, cell phones, or other problem solving techniques such as QFD, Taguchi methods, Six Hats® and Lateral Thinking®, or Creative Problem Solving. If TRIZ advocatesassume that there is something magical or different about TRIZ that makes it easier to accept and adopt, we are deceiving ourselves.

2. Any new technology has competition. To assume that any competition is going to instantly get out of the way and disappear is naïve. In the case of new thinking and problem solving methodologies, the resistance is not always in the form of pricecutting, hiring away key people, or the numerous other activities that are sometimes seen in product competition. However, the investment already made by organizations and individuals in those organizations in other tools can be a significant barrier.

3. Everyone’s plate is very full and nearly everyone is overcommitted in time and resources. Learning anything new, whether it is TRIZ or any other new tool, takes time. To ignore this simple fact and not have the patience to deal with it will lead to frustration and commercial failure.

4. New technology adoption varies with organizations and within organizations. There have always been early adapters and late adapters in any industry, and in any technology area. It is important to figure out who these people are and work with them to accelerate the adaption process. The factors mentioned above are still issues, but potentially less so. Technology adaption within organizations also varies greatly. Much less frequently than 20 years ago, a senior leader in an organization has a clear vision and decrees that a certain process and tool will be used. This does not guarantee ultimate success, but it does get things started. A far more likely scenario in today’s business world is that general interest from a senior leader generates a search to find a volunteer and champion who will try the new process and tool. Then the experience is shared and slowly pollinates within the organization.

5. Learning and problem solving processes vary a great deal by individuals and by organizations. It is important to know these different styles and how they can affect the style in which TRIZ training and problem solving should be done. Let’s take each of these issues and barriers one at a time and discuss them.

TRIZ as a New Technology

People have been solving problems for thousands of years with many different kinds of tools, processes, and techniques. It is hard for many people today to believe that problems were solved without computers, but they were as little as 40 years ago. Most engineers and scientist have heard the story of the first market projections for computer printers by HP as being no more than 500 per year and carbon paper would live forever (has anyone even seen a sample of carbon paper lately?). However, these transitions did not occur instantaneously and without pain, despite the fact that in hindsight they were tremendous inventions that we now find we must have.

In this particular case, what is it about TRIZ that is different? That might make it difficult to accept? Let’s look at the fundamentals of the methodology. First there is the concept of Ideality or Idea Final Result. Only children can think this way easily. By the time engineers have graduated and faced many jaw boning contradictions that they could not resolve, the concept that there is value in dreaming and imagining a contradiction free situation is very difficult, and to many, impractical and useless. The use of compromise as a design philosophy is very strong! What can help here is examples and illustration of where compromise has been overcome with TRIZ. Many corporate clients obviously require confidentiality and these examples are hard to come by. One role for the Altshuller Institute might be as a “storage†for examples which clients have allowed to be shared. Most design engineers are, by nature and by training, analogous thinkers, and anything that provides examples helps tremendously. Case studies are a key to education and understanding, especially case studies form the real world that our customers live in.

The second step in this process of acceptance is to get people to understand that the need for compromise is driven by the existence of contradictions. Most western engineers have lived with contradictions for years and it is their job security! The fact that resolving a contradiction might eliminate a complicated design in which an engineer has invested hundreds of hours of efforts can actually seem to be job threatening rather than being a productivity enhancement. TRIZ session leaders need to think ahead to a typical TRIZ problem solving session, that lasts only 3 days, generating a breakthrough solution to a problem that had generated a less than satisfactory solution and for which an organization spent thousands of dollars and months of time. All TRIZ problem solvers have seen TRIZ professionals salivate and run toward contradictions because they know that is where the opportunity is. We must recognize that most of our clients, seeing a contradiction, see bottles of extra-strength pain relief pills. An effective technique here is to borrow from other creative process techniques and get people to close their eyes and imagine the ideal world without compromise. This kind of group thinking process is used regularly in other types of creative sessions. After this exercise, one can encourage the engineers and problem owners to imagine what their life would be like without unresolved contradictions and design conflicts. Getting people to draw pictures of ideality is also an effective technique because it can start the journey. Another incentive is to get the engineers to think about what they could be doing instead of what they are currently doing. Would they rather be working on the next generation of a product or system, or fixing all the problems in the current design? Would they rather be scaling up a new product or process, or being called out on the midnight shift to fix something that never quite works right? Positive incentives work far better than fear of job security in motivating people to try new things, whether it is TRIZ or anything else.

Consider the Competition

We have all seen many pictures of “S†curves as representations of systems’ evolution, growth, and eventual decline. Any mature industry or technology that is not actively trying to reinvent itself fights back with a vengeance. In the case of problem solving techniques, the resistance doesn’t always come in the form of outright negativity, but from the simple fact that thousands of dollars may have been spent training and problems and have a positive reputation. These existing problem-solving processes have, in large corporations, utilized sometimes tens or hundreds of trainers and thousands of dollars in training materials. Personal credibilities are frequently at risk, especially when a senior executive has committed to a program.

In the case of few or no existing problem solving tools (a rare case), the challenge is far easier, but the demonstration of the uniqueness of the tool is still required. The amount of inertia to overcome is also directly proportional to the amount of money the potential user is expected to invest to try the new tool.

One of the fatal mistakes that can be made is to attack these existing tools as inferior or useless. It is far better to take the time to understand how the existing tool is being used and then figure out how to complement and improve it. Offering to run an inexpensive experiment for a potential user can also help to overcome resistance. Collaboration rather than confrontation should be the rule. Everyone attempting to sell TRIZ to a potential user needs to be able to clearly state how TRIZ can improve and complement QFD, Creative Problem Solving, Six Hats®, Lateral Thinking®, Taguchi methods, Six Sigma, and other tools. There is no organization that is not using some or all of these tools. They will not adopt TRIZ or any of its software embodiments without understanding how it will complement or cost-effectively replace them.

Some TRIZ advocates draw a large TRIZ circle, and all other problem solving tools around it, as if it were the center of the universe. This is not the way to get TRIZ accepted. TRIZ advocates must recognize that there is value in many of the tools and identifying the collaborative and complimentary space is the best way to start.

The Plate is Full

Many times a potential user telling TRIZ advocates that their commitments are overwhelming, and that they have no time to evaluate TRIZ, is discouraging. Sometimes advocates hear about the new product launches that are underway. And other times they hear about the massive investment being made in another problem solving tool (Six Sigma is the latest), which brings up the competitive issue discussed previously. In this case, there are two approaches. Advocates can put potential users in their tickler file and follow up when appropriate. This is frequently the right approach, depending upon the situation. The second is to try to figure out how TRIZ can help make the plate less full. This requires more patience than most advocates normally have. It requires spending enough time with the customer to understand what is overwhelming them and how they can be helped. Frequently, getting the potential TRIZ users to express their frustrations in terms of contradictions is a good place to start. Then the basic concept of TRIZ problem solving can be brought up for discussion.

One of the other commentaries that is heard is that “we don’t need any more ideas, we need to implement the ones we have.†TRIZ practitioners know that the basic problem solving principles they use can be used in either situation, but they too often narrow the application of the principles. One of the most gratifying things that this user has seen in the past few years is the application of the TRIZ principles to organizational and management issues. The use of the Ideation TRIZ Problem Formulator® has been especially useful in this regard.

All people who have run TRIZ problem-solving sessions know that the discipline that they use in TRIZ to properly define the problem is the most useful and important part of the methodology. They constantly see new awareness develop after the correct kinds of problem definition questions have been asked. The truly cost-impacting aspect of TRIZ can be in this phase. The amount of time and money that organizations spend on solving the wrong or poorly defined problem is incredible. This is the aspect of TRIZ that is most marketable to groups with full plates, because every poorly defined problem is spending valuable resources that can be better used elsewhere.

Technology Adoption

An organization adopting TRIZ is no different from an organization adopting bar coding or laser video inspection. It is something different that changes the status quo. There are whole companies and organizations that thrive on being the first to adapt new technologies and leading their peers. Others prefer to see others take the risk and invest later. They are taking the chance that the expensive learning is more of a risk than the waiting. TRIZ advocates must recognize that the use of TRIZ is a paradigm shift in how problems are both analyzed and solved, and that everyone is not prepared to be a paradigm shifter.

It is usually easy to tell the difference in conversations with representatives of organizations, or by reading the literature, patent filings, talking to other consultants, etc. Pairing up with rapid technology adopters is highly preferred.

If one looks at the adoption of certain types of quality and manufacturing processes, it is seen that the top of the food chain drives them. If someone is a supplier to the Ford Motor Co., and they do not choose to follow Ford’s supplier requirements, they will not be a Ford supplier for long. Using TRIZ in joint problem solving and product design sessions with supplier and customers in the room together can be very powerful. This obviously requires a co-operative, trusting relationship between the parties involved. The joint use of TRIZ could greatly accelerate the adoption of TRIZ in a particular industry, especially if the results were published.

Recognition of Different Learning Styles

In addition to differences in organizational adoption, there are distinct differences in how individuals learn new things. At Idea Connections, we have begun to use Michael Kirton’s KAI assessment tool as part of some of our Ideation TRIZ sessions. This is a globally validated psychological assessment tool that measures the style in which people styles. Some individuals think and solve problems in a more incremental way, requiring a stimulus to be creative. Others are capable of ideation without stimulus or structure. Note that we are talking about HOW people solve problems, not WHETHER they can solve problems. We have found that this provides a framework for discussing the analogic thinking process which is such an integral part of TRIZ, as well as providing a framework for group discussions about different ways of thinking about problems. TRIZ software products provide both stimulus and structure, assisting both types of problem solving. The important point here is to recognize that different people learn differently and ignoring this important fact can make training and adoption of a new tool like TRIZ a less than efficient process.

In figure 1 is shown a Problem Formulator® diagram from the Innovation Workbench® software representing one view of the adoption of TRIZ problem solving within an organization. One can readily see some of the conflicts present by looking at function boxes with both red (negative “causes†arrows) and green (positive “provides†arrows) coming out of them. These would be the primary areas in which the problem solvers

would typically focus. These areas are:

1. Starting the TRIZ program

2. Training sessions

3. Solving difficult problems

4. New problem definition approach

5. Generation of an exhaustive solution list

Let’s look at each of these in conjunction with the idea list (see figure 2) generated by the Innovation Workbench® software:

Starting the TRIZ Program

If an organization already is overloaded with organizational programs, the introduction of another one can frequently result in sabotage from key members of the organization whose support is urgently needed. The idea list generated by the IWB® software (statements 1-4, Figure 2) point toward the direction of blending the introduction of TRIZ into broader, existing organizational programs. If portions of TRIZ can be added into existing programs without fanfare and their value demonstrated, the cost will be reduced and the resistance will go down, while organizational support will increase.

Training Sessions

The idea list from the software (statements 36-39, figure 2) also point toward the use of alternative ways to do TRIZ training that will improve effectiveness, reduce time, and minimize meetings. The obvious thought here is the Internet and non-meeting based training. There are downsides to this approach in that students cannot learn from each other, but the speed and flexibility of learning may more than make up for this negative factor. There is some experience in this area with Semyon Semansky and Ideation International, but published information about such experiences are rare, and the TRIZ community will have to wait for additional organizational information to emerge.

Solving Difficult Problems

One of the most fascinating psychological observations, made by this author in TRIZ session that he has run, is the reaction of experienced engineers to the sudden realization that years of work, which had resulted in more and more complicated engineering designs, was, in a matter of few days, made obsolete through the use of the basic TRIZ principles of ideality, as well as the identification of unrecognized resources. On occasion, this has resulted in subtle forms of sabotage of the TRIZ generated ideas. The software directions (statements 8-13, figure 2) suggest that enhancing the solutions to difficult problems is a helpful direction. What could this mean? For one thing, management should make it clear that long-standing problems standing in the way of significant new organizational objectives need to be solved to allow new opportunities to be attacked. It should be made clear at the start of a TRIZ problem solving session that no one is going to be “punished†retroactively for having one of their “pet†solutions be shown to be obsolete. It should be made clear that adoption and support for a new breakthrough problem solving technique is expected by all.

New Problem Definition Approach

The software suggestion of enhancing the new problem definition approach (statements 6-8, figure 2) sounds simple, but it is one of the keys based on the author’s experiences. No matter what problem solving approach is currently in use, the problem definition will always take short shrift. Most engineers cannot resist moving into the solution space, but history tells us that vast amounts of money are spent solving the wrong or inadequately defined problems. Tools such as the Problem Formulator® only add to this up front problem definition effort. This author has yet to see a problem solving team not significantly redefine their problem in the course of using this tool. The only way to deal with this is for the advocate using TRIZ to explicitly state the upfront time required and the value that will result. Experiences from other problem solving session can also be shared. Providing a group the opportunity to share organizational experiences with solving poorly defined problems can also help this process.

Exhaustive Solution Set List

One of the real assets of the TRIZ problem solving process is the generation of a nearexhaustive solution set list. TRIZ practitioners recognize this as a real positive aspect of the methodology, but many problem solving groups are overwhelmed by the output of the process, especially with the use of software such as the Innovation Workbench®. In working with a group, it is important for the facilitator to make the point that the best solution can only be obtained by making sure that all solutions have been considered. Management can reinforce the point that committing millions of dollars to new projects can only be done in confidence when all options have been considered. The other point that can be made in the direction of “enhancing the exhaustive solution list†is to recognize the value in such a list from the standpoint in intellectual property strategy.

Even if the organization cannot afford or chooses not to pursue all directions, patent claims can be filed which may result in licensing revenue. The handling of large idea lists can also he enhanced by sharing the evaluation task among several individuals and groups. This not only spreads the workload, but also provides the opportunity to obtain divergent idea inputs. Directions relating to this area are in statements 32-35 in figure 2. In summary, we must consider a large number of external factors and issues when deciding how to approach different kinds of customers with out TRIZ tools. Tailoring our approach and how we use our various tools can be the key to successful implementation and sale of TRIZ software and consulting.

FIGURE 2

IDEA LIST DERIVED FROM THE INNOVATION WORKBENCH® PROBLEM FORMULATOR® DIAGRAM IN FIGURE 1

1. Find an alternative way to obtain [the] (TRIZ program starts).

2. Find a way to enhance [the] (TRIZ program starts).

3. Find a way to resolve the contradiction: [the] (TRIZ program starts) should exist to obtain [the] (New problem definition approach) and (Training sessions), and should not exist in order to avoid [the] (Competition with current programs) and (Additional costs).

4. Find a way to do without [the] (TRIZ program starts).

5. Find a way to eliminate, reduce or prevent [the] (Competition with current programs).

6.Find an alternative way to obtain [the] (New problem definition approach).

7. Find a way to enhance [the] (New problem definition approach).

8. Find a way to resolve the contradiction: [the] (New problem definition approach) should exist to obtain [the] (Improved project selection) and (Difficult problems are solved), and should not exist in order to avoid [the] (Time consumption).

9. Find a way to do without [the] (New problem definition approach).

10. Find an alternative way to obtain [the] (Difficult problems are solved).

11. Find a way to enhance [the] (Difficult problems are solved).

12. Find a way to resolve the contradiction: [the] (Difficult problems are solved) should exist to obtain [the] (Higher profits), and should not exist in order to avoid [the] (Professional embarrassment).

13. Find a way to do without [the] (Difficult problems are solved).

14. Find an alternative way to obtain [the] (Improved project selection).

15. Find a way to enhance [the] (Improved project selection).

16. Find a way to do without [the] (Improved project selection).

17. Find an alternative way to obtain [the] (Higher impact projects).

18. Find a way to enhance [the] (Higher impact projects).

19. Find a way to do without [the] (Higher impact projects).

20. Find an alternative way to obtain [the] (Higher profits).

21. Find a way to enhance [the] (Higher profits).

22. Find a way to protect [the] (Higher profits) from the harmful influence of [the] (Additional costs) and (Poor projects).

23. Find a way to do without [the] (Higher profits).

24. Find a way to eliminate, reduce or prevent [the] (Additional costs).

25. Find a way to increase the effectiveness of eliminating [the] (Poor projects) by using [the] (Improved project selection).

26. Find an alternative way to eliminate, reduce or prevent [the] (Poor projects).

27. Find an alternative way to obtain [the] (TRIZ is accepted).

28. Find a way to enhance [the] (TRIZ is accepted).

29. Find a way to eliminate, reduce or prevent [the] (Professional embarrassment).

30. Find a way to eliminate, reduce or prevent [the] (TRIZ is rejected).

31. Find a way to eliminate, reduce or prevent [the] (Time consumption).

32. Find an alternative way to obtain [the] (Exhaustive solution list).

33. Find a way to enhance [the] (Exhaustive solution list).

34. Find a way to resolve the contradiction: [the] (Exhaustive solution list) should exist to obtain [the] Difficult problems are solved), and should not exist in order to avoid [the] (Time consumption).

35. Find a way to do without [the] (Exhaustive solution list).

36. Find an alternative way to obtain [the] (Training sessions).

37. Find a way to enhance [the] (Training sessions).

38. Find a way to resolve the contradiction: [the] (Training sessions) should exist to obtain [the] (Difficult problems are solved) and (Exhaustive solution list), and should not exist in order to avoid [the] (Time for meetings) and (Time consumption).

39. Find a way to do without [the] (Training sessions).

40. Find a way to eliminate, reduce or prevent [the] (Time for meetings).

INTUITIVE DESIGN METHOD (IDM), A NEW APPROACH ON DESIGN METHODS INTEGRATION

ABSTRACT

When facing today’s world competition, the concept of “fastinnovation†that allies both innovation and time to market, is a surviving matter. In the science of new product design, many different approaches have been formalized, but most of this scientific work has been performed at academic level. In this paper we discuss about a new approach to use these design methods in order to build an “Intuitive Design Methodâ€(IDM), based on previous knowledge and technological background of the company. Based on these acknowledgements a flow chart of Intuitive Design Method building will be presented. Then, a case study will support our approach. This case study has been conducted in M.G.I. Coutier one of the French automotive supplier leader and the presented product will be an intake manifold. Both these theoretical and practical approaches will lead us to a conclusion that demonstrate the usefulness of the IDM model, and that there is no metamethod that can be apply to any company, but a dynamic set of existing basic rules. These rules have to be formalized in order to significantly increase engineers abilities to conduct and to optimize a total design process. Keywords: Design methods, Intuitive Design Method, Methods integration, Design process

1 INTRODUCTION

Companies have ever been confronted with the question of development. In the face of competition, the ever more rapid emergence of new products, changing consumer fashions and globalisation, they are forced to call into question the efficiency of their design methods to keep their competitive edge and ensure their survival. Within this very general frame, work on design methods has always tended to foster one or other dimension of the process, which isolates the notion of need from the industrialized product.

Moreover, in almost all books and international publications presenting the most advanced work on design, key references are credited to the 3 major economic and industrial centers, i.e. the USA, Japan and Europe. And yet, geographically speaking, the scope of knowledge on Earth is not limited to these 3 major centers. Fundamental importance must logically be awarded to the former Soviet Union in fields belonging to the so-called pure sciences (mathematics, physics, chemistry etc.).

During our research, we have had contacts with some of these countries on several occasions (Russia, Belarus, Ukraine, Azerbaijan and Moldavia etc.) and the foundation for our research paradoxically stems from our discovery that some areas of industrial knowledge had experienced developments in the former Soviet Union of which we were completely ignorant. We also realized that they were going to help provide us with answers. An acceptable model of the design process, based on an analysis of several contacts with the academic and industrial world, must meet a large number of requirements [Nordlund (1996)] . To establish this type of model, a survey of existing design methods was conducted.

Choices concerning the selection made for the rest of this thesis result from an analysis of what exists in the industrial and academic fields on the subject of design. The convergence of these two worlds sometimes gives common standpoints on certain methods which have been deemed relevant and are used for their capacity for meeting the designer’s needs.

2 SUMMARY OF THE DESIGN METHODS

The methods analyzed are Value Analysis (VA), QFD, Axiomatic Design (AD), the Pahl & Beitz approach (PB), Concurrent Engineering (CE), Robust Design (RD), Design for Manufacturing (DFM) and the TRIZ method. After analyzing the various design methods, our initial reaction was that confusion reigns as to what they can offer the designer. Indeed, while they all advocate that they can act as a reference in terms of how a design project should be conducted, they rarely make allusions to what could be perceived as complementarity between them. This state of affairs often leads to redundancy in terms of the answers they provide for the designer.

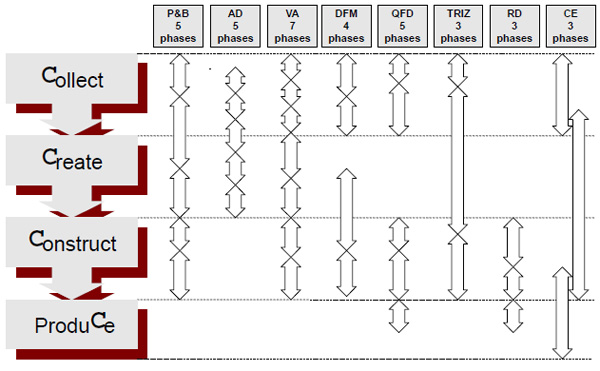

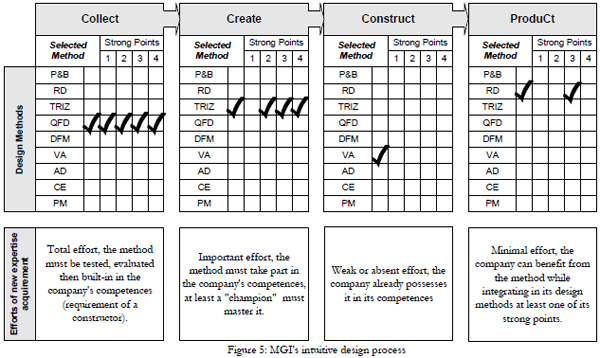

If we adopt an abstract dimension for the methods studied, the various representations of the development process provide us with a common vision centered on 4 essential phases1: data collection and analysis (Collect); creation (Create); construction (Construct); and growth (ProduCe).

3 CONTRIBUTING TO INCREASING EFFICIENCY IN THE DESIGN ACTIVITY: IDM

The four phases clearly pinpoint the essential notions for all the methods in our study. Since they are highly generic, they provide a structural approach to the project and in no way consist of a rigid, fixed structure. This abstraction phase will enable us to put forward hypotheses as to the use of one or more “strong points” associated with a method and to link them up to one or more strong points in another.

We should remember that no method takes the methodological history of the company into account. Their structure is fixed in relation to this and any company that operates one method or another (or sometimes merely rules) is therefore obliged either to train themselves regarding the new method they wish to adopt, or to adapt it to what already exists in their company by acting intuitively in terms of its integration.

Backed by this statement of fact, our analysis is therefore based on a prior survey of what exists on a methodological level. This survey is then used in a logical fashion to build up the integration strategy best suited to the company. Our conclusion is that ideally, the designer should be able to increase the relevance of his project with a minimum number of changes to his design habits. In order to do this, we offer to draw up a survey of the strong points of each method with the aim of detecting any deficiencies in terms of relevance in the project and to bridge these deficiencies, not by integrating a method wholesale, but by integrating its strong points alone.

Once the state of the art of the strong points in design methods has been formalized and since the methodological and technical knowledge of the company is a known factor, it becomes possible to deduce which intuitive design method may be most appropriate for a given company. When following this procedure, it would seem essential to draw up a document to process the company’s data. Furthermore, this document must be designed so that it can be drawn up rapidly and it must be easy to use. The findings of this type of analysis should provide the final choice of strong points in each method for each stage of the project.

Time being an important factor for companies with regard to this type of analysis, we believe it is important to underline the company’s skill-building efforts at each stage of the project so that this can be recorded in the document, if necessary.

3.1 TRIZ’S CONTRIBUTION TO THE SCIENCE OF DESIGN [SOUCHKOV (1998)]

In the light of the comparative analysis we have conducted, the method appears to be atypical in terms of its contribution to design methods. Indeed, its relevance and operational profile are fundamentally different from those of other methods studied. This is particularly true for the creativity phase which, although its is barely relevant in other methods, is the strong point of TRIZ, since the methodological effort of a company wishing to improve its design process will no doubt occur with TRIZ.

4 INTEGRATION METHOD

4.1 DIFFICULTIES IN APPLYING TRADITIONAL METHODS

In the introduction to this section, we will give a brief summary of the difficulties linked with applying the design methods quoted in the previous section. The term “difficulty” encompasses in particular:

• Learning difficulties: this arises from the fact that the methods have often been developed in research laboratories and are still not widespread in companies. The fact that training programs for some of them are virtually nonexistent in engineering courses adds to the fact that the learning process presents a difficulty for the industrialist.

• Difficulties linked with doubts surrounding the profitability of the investment. The financial aspect obviously presents a difficulty and a major obstacle to the integration of the new method. The economic context merely accentuates this difficulty since it is not easy, on first contact with a new method, to grasp the return on investment in man-hours that it will generate. The training/counseling aspect is added to the cost as soon as it becomes apparent that the company lacks skill with regard to the method.

4.2 MEASURING THE GAP

Our analysis of the various design methods has revealed a certain amount of complementarity, which has sometimes led to research work [Malmqvist (1996)] [Schulz (1999)] . It would seem logical that the ideal combination would consist in collecting and analyzing data with QFD, generating concepts with TRIZ and ensuring the optimization of parameters with Robust Design [Verduyn (1995)] . Yet this combination is only ideal from a theoretical point of view. A whole panoply of difficulties awaits designers who wish to combine these methods.

• Difficulties in skill-building for a set of methods which are not mastered.

• Difficulties in combining methods in the same project or the need to create interfaces between them.

• The time-span of the project is increased significantly due to the inertia inherent in applying three methods. Our conclusion is that ideally, the designer should be able to increase the relevance of his project with a minimum number of changes to his design habits. In order to do this, we offer to draw up a survey of the strong points of each method with the aim of detecting any deficiencies in terms of relevance in the project and to bridge these deficiencies, not by integrating a method wholesale, but by integrating its strong points alone.

4.3 HIGHLIGHTING THE STRONG POINTS OF DESIGN METHODS

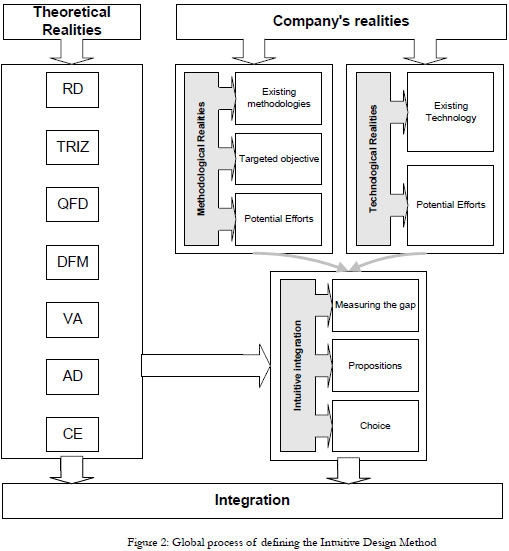

The classification of strong points for each design method has been formalized and deliberately restricted to four since, beyond this number, it becomes difficult to identify the real advantage of the point in question. The object of this formalization is to offer the company a strategic choice in its decisions regarding the orientation of its design method. The stages and generation of the intuitive design method Since the state of the art of the strong points in design methods has been formalized and the methodological and technical knowledge of the company is a known factor, it is now possible, according to the following graph (figure 2) to deduce which intuitive design method may be the most appropriate for a given company.

5 IMPROVEMENT IN THE PERFORMANCE OF THE DESIGN ACTIVITY AT MGI COUTIER

An industrial application has been developed within the frame of this research activity. It was conducted at the company MGI Coutier (an automobile parts manufacturer). The project selected as the presentation medium was the intake manifold. The intake manifold is an important element in the gas inlet zone of the cylinders. Its shape and the lack of space available under the bonnet mean that today, it is an element which has undergone little optimization in terms of its structure and shape. With the aim of improving its performance in use, the intuitive design method developed in our research project has been applied to generate innovative concepts which may solve the major problem related to its shape.

5.1 INCREASING DESIGN EFFICIENCY The MGI design method

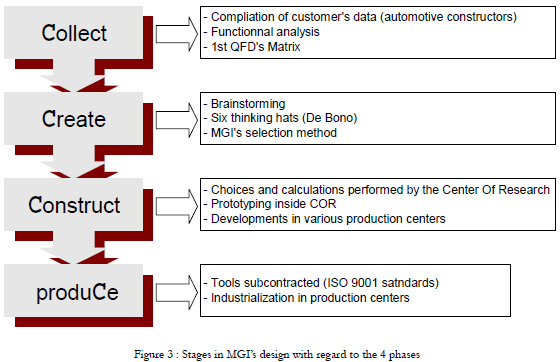

As with several of the companies we contacted, MGI have their own design method. Based on the current know-how of the engineers and past experience in applying different methods with varying degrees of success, MGI uses an “integrative and associative” procedure with regard to the 4 phases in the following form:

The specificity of design activity at MGI lies in the fact that upstream research and computation are centralized at a research center located in the Bas-Rhin in France. This research center employs some 40 engineers and 20 technicians and is in charge of research on new products and systems. The notion of novelty lies in the aptitude of development centers to conduct a study independent of the research center (re-looking, minor developments etc.). Upstream studies requiring the backing of research (materials, process, technology, innovation etc.) are initially dealt with by the research center before being transferred to development and industrialization in the various development centers. It should be noted that development centers may deal with a study independently while, in terms of resources, calling solely on the computational center (simulations, flow, analyses etc.).

Analysis of the efficiency of the design activity Using items returned by customers and personal analyses as our basis, we were able to compile data on the aptitude of MGI’s project teams to overcome the obstacles inherent in the 4 phases. We noted that the collecting phase is heavily invested by QFD [Hauser (1988)] due to the fact that one of MGI’s sizeable contractors impose skill-building on them for this tool, underlining the importance of mastering this method. Synthesis and recommendations for skill-building in MGI’s design activity

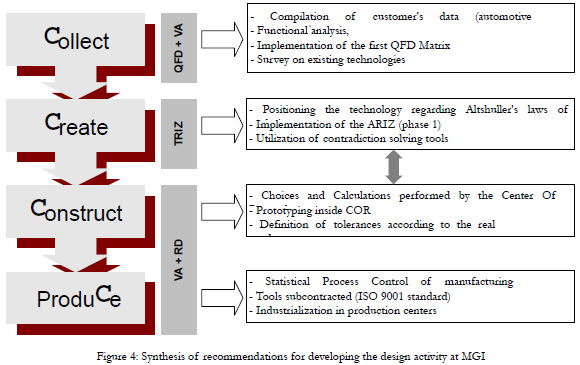

Figure 4 clearly demonstrates the importance of investment in training and expertise for the company, in particularly for the Collect and Create phases.

Details on the actions undertaken to increase efficiency in design

Our assessment suggests that two key actions should therefore be undertaken:

• The first concerns the acquisition of the strong points in TRIZ (in particular with problem-solving tools). A training course lasting 5 days has therefore been set up to reach this target. We have also suggested to MGI that one person should be selected from the trained group to become the “inhouse” specialist who will be the resource person for future applications.

• The second aims to improve appropriateness in terms of industrialization (in particular for plastic parts), the real specifications required by the customers and the technological capacity of the production tool [Taguchi (1987)] . In this framework, some notions of robust design are put forward in a second training course lasting 5 days. This second point is nonetheless more complex to grasp since the development units which need to be associated with the process are numerous and therefore investment is high.

We will nonetheless put it to MGI that a specialist in Robust Design should be trained in an attempt to transfer part of the knowledge acquired to future actors in the design phase.

5.2 APPLICATION FOR A PRACTICAL CASE: THE INTAKE MANIFOLD

Generating an application method for developing concepts From the strong points which have arisen from the design methods, we were able to build an intuitive design method adapted to MGI’s industrial reality. Initially, the different phases were formalized. The aim was to apply all the tools best adapted to the project. The problem posed presented a need for largescale development. Particular effort will therefore be focused on the phases upstream to the design stage so that the utmost may be done to ensure that the ensuing concepts are innovative. The drawback here is that the ensuing concepts will probably require research in the medium term. Figure 5 gives a summary of these steps and the expected objectives.

Findings of the computational study

The study on the manifold called “4-in-1divider” demonstrates that in order to obtain optimum engine fill, the length of the pipes must be varied. If the volume of the plenum chamber is altered, the results are low and may even be slightly negative. A variation in the diameter of the pipe inlet is harmful if it results in the pipe having a “divergent-convergent” shape. This analysis demonstrates the full relevance of correlation between the creation phase and the construction phase. The iterations required between these two phases lead us to state that the proximity of the design and computational centers and the multidiscipline approach of the different actors in the design phases largely contribute to the notion of total design.

This study, undertaken using Wave software, allowed us to assess the effects of variations in the dimension on the traditional divider, and then on the new concept of the “4-in-1” divider. We were therefore able to see that this new concept could help develop a divider where the length of the pipes is easily adjustable. Furthermore, another advantage in this divider is that the swirl effect is fully utilized inside the plenum chamber, if the distribution of the pipes is correctly arranged. Wave was unable to modelize this phenomenon (code 1D). Simulation using Fluent (fluid mechanics code) in non-stationary 3D should enable this idea to be validated.

Synthesis on the upstream design study To summarize this upstream study on concept research, the following points have been deciding factors in the reformulation of the problem:

• Highlighting the utility of applying ARIZ [Altshuller (1986)] when no obvious contradiction arises.

• The absolute need to project the system in the radar diagram of the law of evolution. This enabled us, in particular:

* To demonstrate the limits of the system’s operation due to its non-symmetry;

* To demonstrate in which direction concept research should progress: the dynamics of the manifold.

• Finally, the principles of separating physical contradictions [Altshuller (1989)] constitute the most appropriate tools in our situation.

To conclude, the necessary complementarily between the specialist in the technical field under study and the TRIZ specialist who plays a “facilitating” role at key moments in the project has once more been highlighted in this case.

6 CONCLUSIONS

Fundamental sciences are too often ignored in design. This is probably due to the fact that courses in engineering schools for industrial sectors have little room for physics and chemistry etc. The result is that company engineers turn away from these resources and adopt design routines which revolve around the knowledge acquired in their specific discipline alone. Reducing mechanical systems to simple principles of physics can, however contribute significantly to the development of the design activity [Souchkov (1996)] .

Creativity too is often left by the wayside when companies make choices in terms of investments to increase their competence in design. The image of creativity as innate knowledge is still present in people’s minds and our findings have often led us to make the following statement: in order to build up competence in the design activity of R&D departments, we believe that the key to success lies in moving on from a logic of innate creativity to a logic of systematized creativity [Altshuller (1988)] .

The metamethod, so sought after in research, probably does not exist. Therefore we believe that setting up an intuitive design method which strays as little as possible from the company’s current method, is the right path to follow. The effort to build up competence thus defined must not only have a bearing on the deficiencies detected in the company. This detection work must be independent from any sectorial polarity since reality is often interpreted differently by each of the actors involved. The purpose behind this dynamic method is to increase the efficiency of design in a given company, and a fresh application will be required for each new company.

7 ACKNOWLEDGMENTS

In this section we would like to thank both the Alsace Region for supporting our research work on TRIZ and its integration with occidental design science and MGI Coutier Company for allowing us to use and publish part of the study we have led with them.

This paper is partly a synthesis of the author’s thesis, entitled “Contribution to new mechanical system design using methodological integrationâ€. The presentation of this thesis has been held in ENSAIS, Strasbourg (France) December 14th 1999.

8 REFERENCES

[1] Altshuller G.S. To Find an Idea: Introduction into the Theory of Inventive Problem Solving, Nauka, Novosibirsk (in Russian), 1986.

[2] Altshuller G.S. Creativity As An Exact Science, , Gordon & Breach, New York, USA, 1988, ISBN 0-677-21230-5

[3] Altshuller G.S., B.L. Zlotin, A.V. Sussman & V.1. Filatov, Search for new ideas: From Insight to Technology (Theory and Practice of Inventive Problem Solving), Karte Moldaveniaske, Kishinev (in Russian), 1989.

[4] Cavallucci, D. Lutz, P. “Beyond TRIZ Limits†The TRIZ Journal, March, 1998.

[5] Cavallucci, D. Lutz, P., TRIZ, Une nouvelle approche de résolution des problèmes d’innovation, International Journal of Innovation Research. N°1 Vol.1 1999.

[6] Hauser, J. R. , Clausing D., “The House of Quality,” The Harvard Business Review, May-June, No. 3, pp. 63-73, 1988.

[7] Malmqvist J., Axelsson R., Johansson M., “A comparative analysis of the theory of inventive problem solving and the systematic approach of Pahl and Beitzâ€, ASME Design Engineering Technical Conference, August 18-22, Irvine, California, 1996.

[8] Miles, L. D., Techniques of Value Analysis and Engineering, McGraw-Hill Book Company, New York, NY, 1961.

[9] Nordlund M., “An Information Framework for Engineering Design based on Axiomatic Designâ€, Doctoral Thesis, Department of Manufacturing Systems, The Royal Institute of Technology (KTH), Stockholm, Sweden, 1996. ISRN KTH/TSM/R-96/11-SE

[10] Pahl, G. and Beitz, W., Engineering design, London: Design Council, 1984.

[11] Schulz A., Clausing D., Negele H., Fricke E., “Shifting the view in systems development – Technology Development at the fuzzy front end as a key to successâ€, Proceedings of 1999 ASME DETC, 11th International Conference on Design Theory and Methodology, Las Vegas, September 12th –15th, 1999.

[12] Sohlenius G., “Concurrent Engineering” Annals of the CIRP, Vol. 41, No. 2 pp. 645-655, 1992.

[13] Suh N.P., The Principles of Design, New York: Oxford University Press, 1990. ISBN 0-19-504345-6

[14] Taguchi, G. System of Experimental Design: Engineering Methods to Optimize Quality and Minimize Costs, Vols. 1 & 2, UNIPUB/Kraus International Publications, White Plains NY., 1987.

[15] Souchkov V., “TRIZ and Technosocial Competition.” The TRIZ Journal, February, 1997.

[16] Souchkov V., Alberts L., Mars N., “Innovative Engineering Design Based on Sharable Physical Knowledgeâ€, Artificial Intelligence in Design’96, J.S. Gero and F. Sudweeks, eds., Kluwer Academic Publishers, pp. 723-742, 1996.

[17] Souchkov V., Mars N., “Knoweledge-Based Support For Innovative Designâ€, PhD Thesis, University of Twente, The Netherlands, 1998.

[18] Verduyn D. & A. Wu, “Integration of QFD, TRIZ, & Robust Design: Overview & Mountain Bike Case Studyâ€, Proceedings ASI Total Product Development Symposium, November 1-3, Dearborn, MI, USA, 1995.

By Alla Zusman, Ideation International Inc.

azusman@ideationtriz.com

©2000, Ideation International Inc.

Editor’s note: This paper shows the application of the Ideation Workbench Method to the case that was presented in the September 2000, issue of The TRIZ Journal.

Innovation Situation Questionnaire

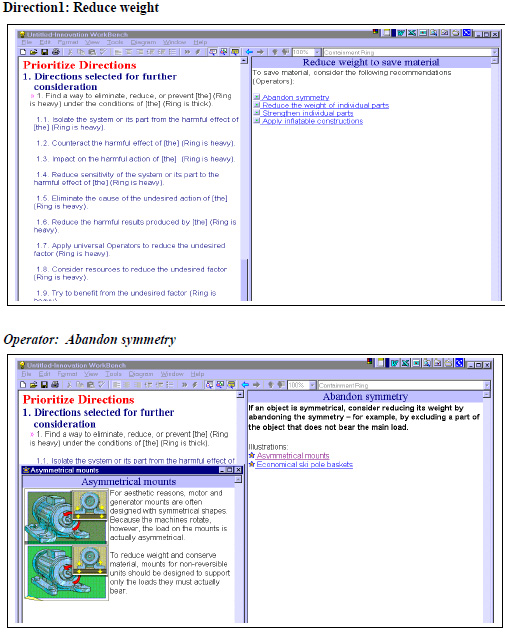

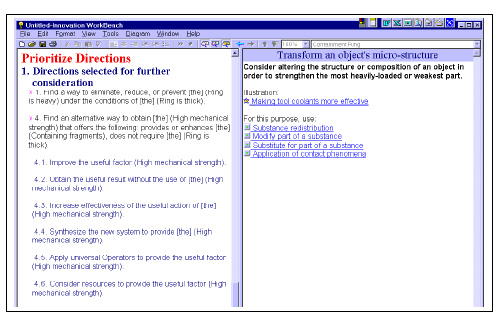

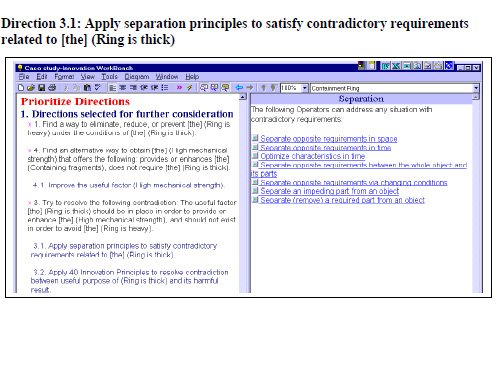

1. Brief description of the problem The engineered system, which is designed to contain the fragments resulting from an impeller burst of a maximum-speed fan, consists of the following: a fan, fan shroud (which controls the direction of the air stream), and an armor-steel containment ring. The problem to be solved is that the ring is too heavy and must be reduced in weight by 50%.

2. Information about the system

2.1 System name The following systemic levels might be considered:

• Containment ring

• Fan

• Air conditioning system

• Aircraft

• Testing of ring

For the ring, the problem is as follows: the ring must be strong to withstand the impact of the impeller fragments, and the ring should not be heavy.

For the fan, the problem is as follows: the impeller can burst, but fragments should not fly away.

For the air-conditioning system, the problem is as follows: the impeller can be broken, but the air should be conditioned.

For the aircraft, the problem is as follows: the impeller can burst, but neither people nor equipment should be harmed.

For testing the ring, the problem is as follows: the ring’s ability to capture flying fragments should be tested, but it is difficult to move the heavy ring back and forth.

Idea # 1 Make the ring as an assembly made of light-weight parts that are easy to move for testing purposes.

We can influence two systemic levels: the ring and the fan assembly. Let’s select the fan assembly as the system to be considered.

2.2 System structure The fan assembly consists of the following elements:

• fan

• motor

• shaft

• motor support

• containment ring

• connectors or support to keep the ring

2.3 Functioning of the system

The primary useful function of the fan is to supply (move) air for the air conditioning system. The fan rotates quickly and moves air. The air is conditioned so that the aircraft cabin can be supplied with conditioned air.

2.4 System environment Other parts of the air conditioning system:

• pipes

• heat exchanger

• airflow distributors

Other systems located nearby:

• aircraft covering

• equipment

Other system interacting with the fan and air conditioning system:

• electrical power supply

• air supply

• exhaust air removal

• vibration dampers

Conditions around the system: indoor conditions

3. Information about the problem situation

3.1 Problem that should be resolved Reduce the weight of the ring by 50%.

The primary harmful function of the given system (the fan assembly) is that impeller fragments fly away if the impeller bursts.

3.2 Mechanism causing the problem

The containment ring must be strong to contain the flying fragments – for this reason the ring is thick and, as a result, heavy.

The cause of an impeller burst is as follows: Rotation of the fan results in centrifugal forces that “pull” the parts of the impeller. The strength of the impeller material can be compromised by material defects and fatigue. As a result, the impeller can burst, causing the impeller fragments to fly off. Due to the high speed at which the fan rotates, the flying fragments carry high energy and can harm people and other parts of the aircraft.

2.3 Undesired consequences of unresolved problem

The high weight of the ring makes it difficult to carry out the routine tests required by the FAA. The “dead weight” of the aircraft equipment is also high. If the weight problem is resolved at the expense of the ring’s strength, the result will be inadequate protection from the flying impeller fragments, which in turn can result in death and/or damage.

2.4 History of the problem

The increased requirements for conditioning the air are met using a higher velocity airflow, but this means that the rotational speed of the fan increases. As a result, an impeller burst becomes more probable and the danger from the flying fragments increases. Because the energy of the flying fragments is increased, the ring must be stronger. As a result, the ring is heavier. Known attempts to reduce the ring thickness resulted in a reduction in strength.

Idea # 2

Provide high airflow with low rotational speed of the fan. Perhaps utilize several slow fans instead of one that rotates quickly

2.5 Other systems in which a similar problem exists

Similar problems exist in many other areas where weight and mechanical strength are critical issues, as well as other systems for protection against flying parts. We do not have any information about how these problems have been addressed.

2.6 Other problems to be solved

Use an alternative method to contain the fragments.

Make the impeller unbreakable.

Others (see the problems on different systemic levels in the beginning of the ISQ).

3. Ideal vision of solution

No containment ring is necessary.

An impeller burst is no longer possible.

4. Available resources

Substance resources

• Material of containment ring

• Material of fan impeller

• Other objects around

• Airflow

Field resources

• Mechanical forces

• Airflow energy

• Electrical energy

• Magnetic field (motor)

Space resources

• Space inside the ring

• Space outside the ring

Time resources

• Time during which the fan is not operating

• Time when the fan is operating

• Time before the impeller bursts

• Time after the impeller bursts

Informational resources: No special resources

Functional resources

• Rotation

5. Allowable changes to the system

• Drastic changes are allowed.

• Any reduction in strength is unacceptable.

6. Criteria for selecting solution concepts

• Weight reduction of at least 30%

• Cost increase of no more than 5%

• About two weeks for new design

• One year for implementation

7. Description of the company business environment (Withheld)

8. Project data

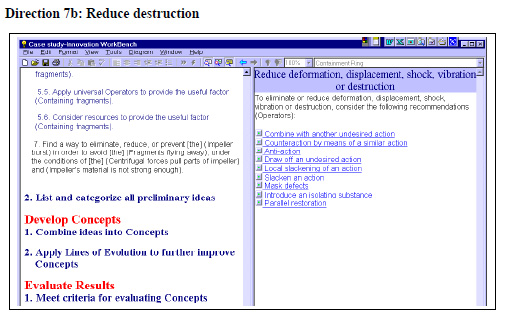

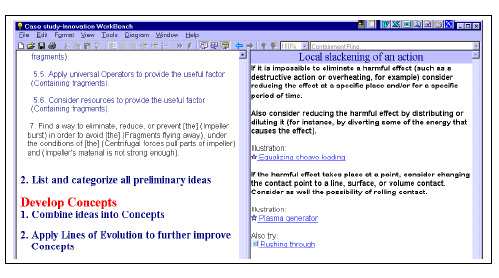

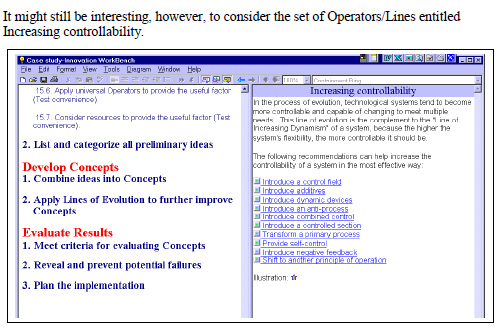

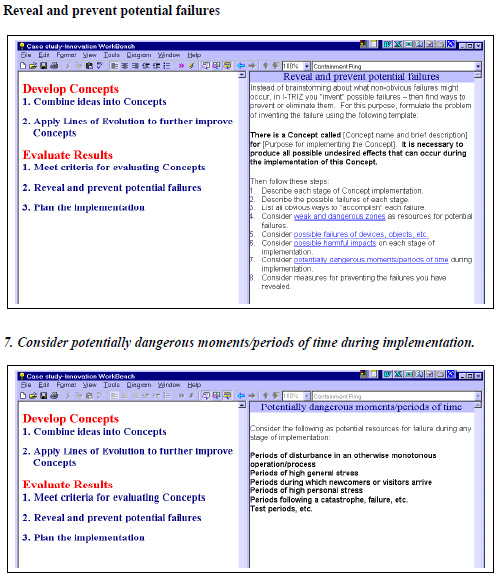

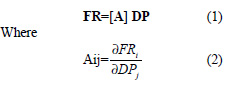

(Withheld) Problem Formulation The Diagram

List and categorize all preliminary ideas

Idea # 1: Make the ring as an assembly made of light-weight parts that are easy to movefor testing purposes.

Idea # 2: Provide high airflow with low rotational speed of the fan. Perhaps utilize several slow fans instead of one that rotates quickly.

Idea # 3: Utilize a “weak” ring that will absorb energy as it is destroyed.

Idea # 4: Perform testing without removing the ring.

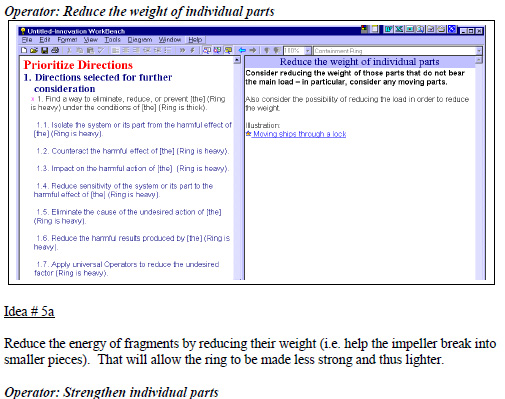

Idea # 5: Reduce the mass of the fragments to reduce damage.

Idea # 6: Vary the thickness of the ring tube, reducing the thickness where permissible.

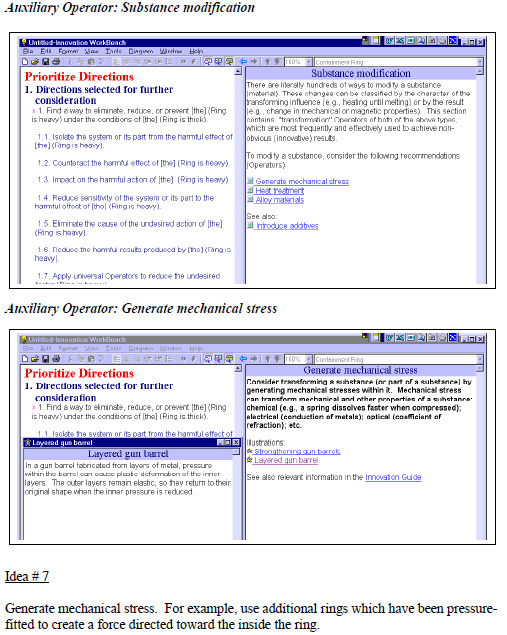

Idea # 7: Introduce preliminary stress. For example, use additional rings which have been pressure-fitted to create a force directed toward the inside of the ring.

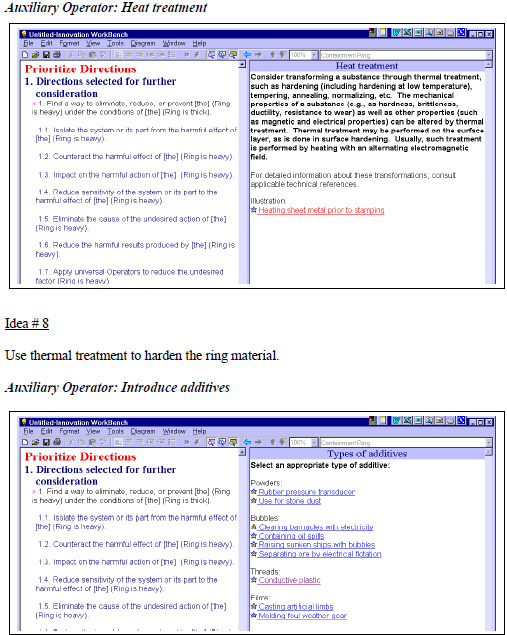

Idea # 8: Use thermal treatment to harden the ring material.

Idea # 9: Use special reinforcing threads (fibers) such as those found in bullet-proof vests.

Idea # 10: Replace the ring with an airbag that inflates when the impeller bursts.

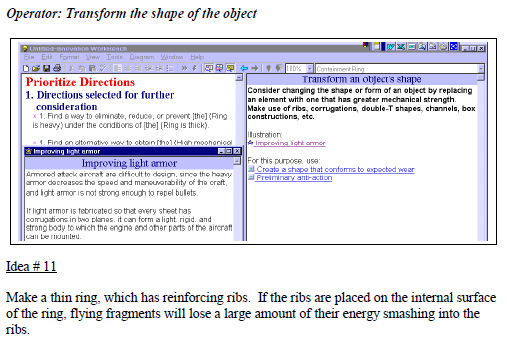

Idea # 11. Make a thin ring that has reinforcing ribs. If the ribs are placed on the internal surface of the ring, flying fragments will lose much of their energy smashing into the ribs.

Idea # 12: Make the ring corrugated in two planes.

Idea # 13: Determine where the ring usually breaks and reinforce those places.

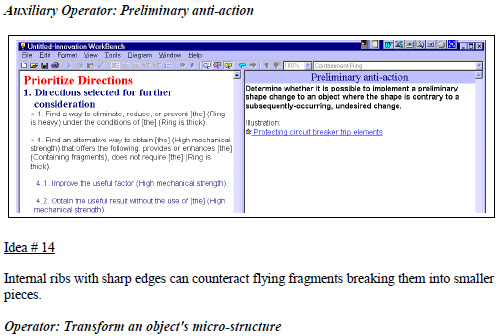

Idea # 14: Internal ribs with sharp edges can counteract flying fragments, breaking them into smaller pieces.

Idea # 15: Use a multi-layer ring: additional strengthening rings, rings having different

hardness and elasticity, rings which have a gap in between them, filling the gap with an energy-absorbing material.

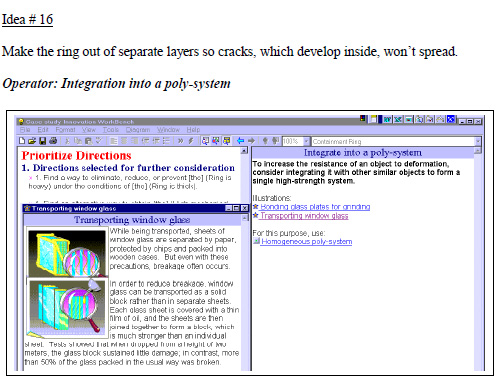

Idea # 16: Make the ring out of separate layers so that if cracks develop inside they will not spread.

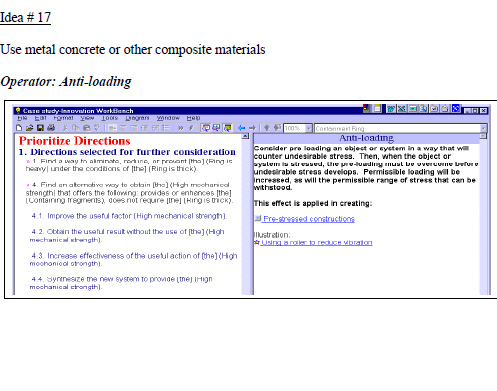

Idea # 17: Use metal-concrete or some other composite material.

Idea # 18: Create inner stresses inside the ring: This can be done using wiring, banding, double ring structure, etc.

Idea # 19. Change the ring thickness or strength or other containment capabilities the moment the impeller bursts.

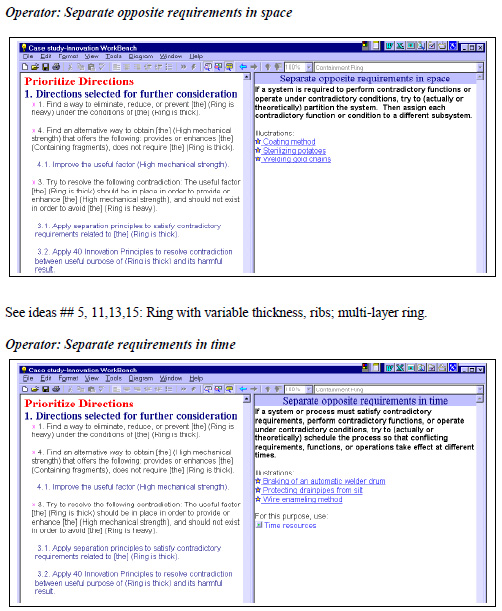

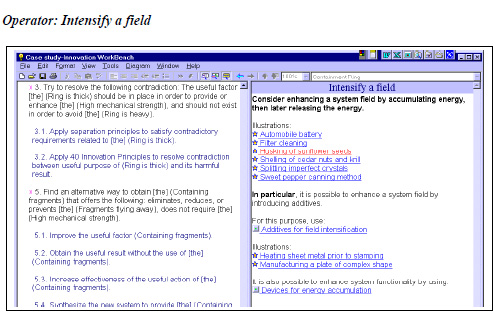

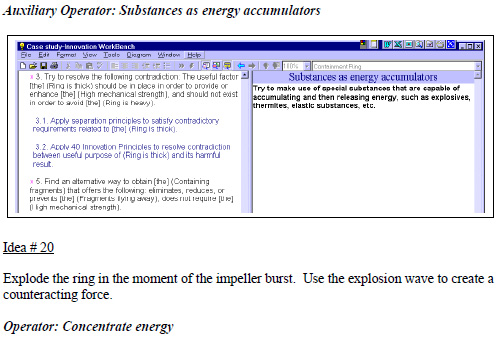

Idea # 20. Explode the ring the moment the impeller bursts. Use the explosion wave to create a counteracting force.

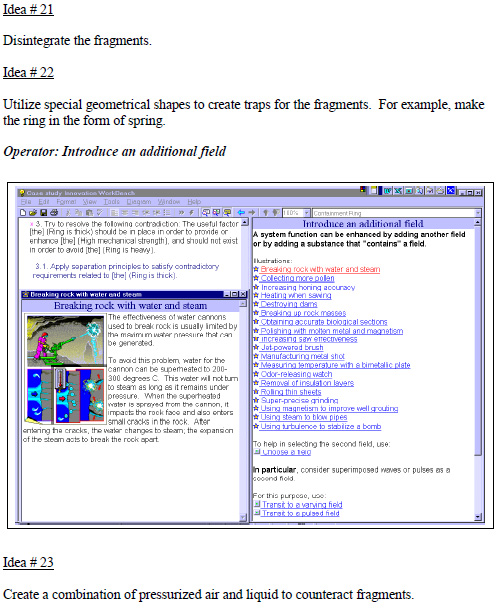

Idea # 21. Disintegrate the fragments.

Idea # 22. Utilize special geometrical shapes to create traps for the fragments. For example, make the ring in the form of spring.

Idea # 23. Create a combination of pressurized air and liquid to counteract the fragments.

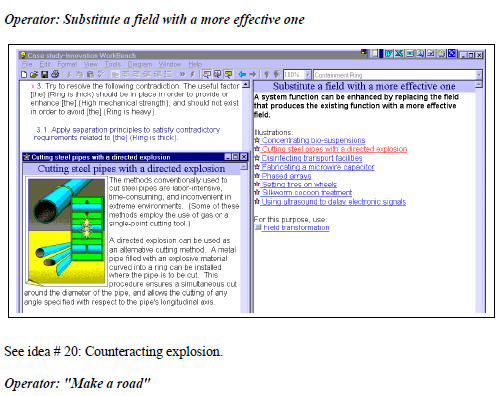

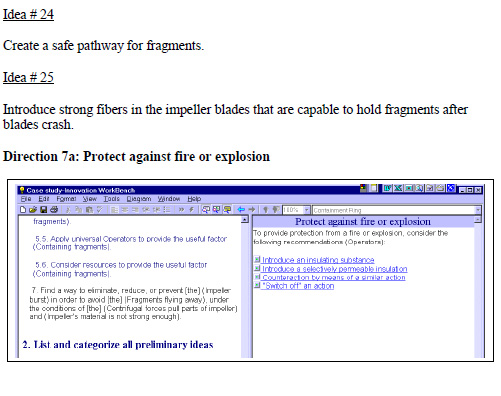

Idea # 24: Create a safe pathway for the fragments.

Idea # 25. Introduce strong fibers in the impeller blades that are capable of holding the fragments after the impeller bursts.

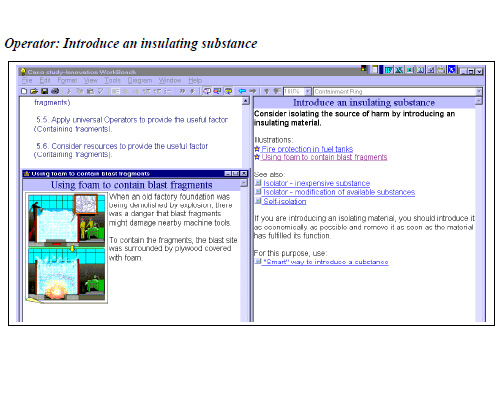

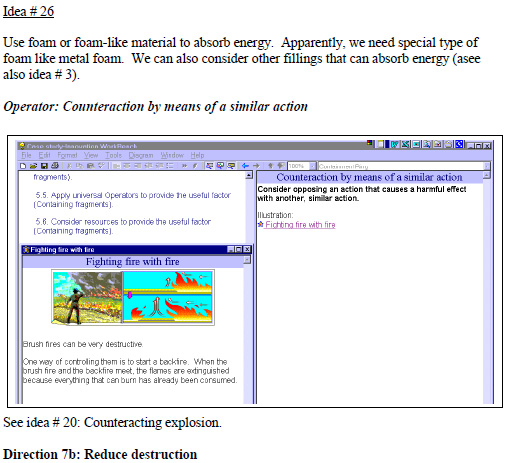

Idea # 26. Use foam or foam-like material to absorb energy. Apparently, we need a special type of foam such as metal foam. We can also consider other fillings that can absorb energy (see idea # 3).

Idea # 27. Define the least dangerous directions and redirect the fragments in these directions.

Idea # 28. Distribute the harmful energy between more of the fragments (see also ideas #7 and 21: reducing energy/mass of the fragments).

Idea # 29. Create a special pathway (spiral) to trap the fragments and to reduce their energy while traveling through the spiral route (see ideas # 22 and 24). Also, see idea #26: absorb the energy.

Idea # 30. Disposable ring – consider that the ring will be destroyed while absorbing all the energy of the fragments (similar to idea # 3).

Idea # 31. Consider various types of support while transporting the ring.

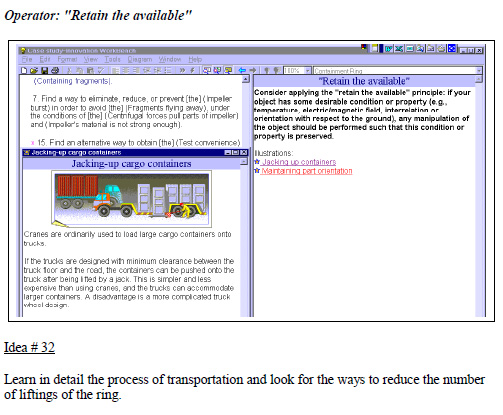

Idea # 32. Learn the details of the transporting process and look for the ways to reduce the number of liftings.

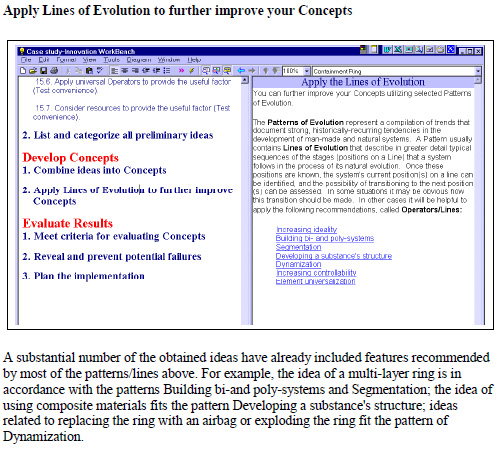

We can categorized the obtained ideas into the following groups:

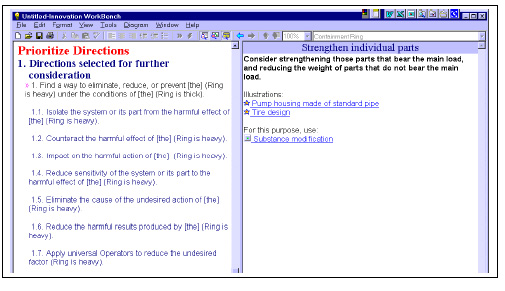

1. Strengthening the ring via

a) changing the ring material structure:

• creating inner stresses (wiring, banding, press-fit) (#18, 7)

• introducing special reinforcing threads (fibers), using metal-concrete or other composite materials (# 9, 17, 25)

• special thermal treatment for hardening the ring material (# 8)

• using a multi-layer ring with layers with different properties (elasticity, hardness,

gaps filled with energy-absorbing materials) (# 15)

b) changing the ring’s shape:

• vary the ring thickness to best accommodate the situation (# 6,13)

• create various reinforcing ribs (# 11)

• use two-plane corrugations (# 12)

2. Increasing the ring’s energy-absorbing properties via

a) changing the material structure:

• using foam and/or foam-like materials (metal foam, honeycomb, wiring, brushes) (#3,23, 26, 30)

• using a multi-layer ring with layers capable of moving relative to one another to absorb extra energy

b) changing the ring’s shape:

• spiral or other traps that can slow down the fragments (#22)

3. Reducing the mass/energy of the flying fragments to reduce damage and allow the ring’s mechanical strength to be lowered via

• changing the ring’s material structure to make it capable of breaking into smaller pieces (# 5, 21,28)

• introduce ribs with sharp edges capable of breaking fragments into smaller pieces (#11,14)

4. Improve testing convenience, including:

• perform the test without removing the ring (# 4)

• make the ring dismountable and transport parts of the ring rather than the whole thing (# 1)

• consider various types of special support during ring transport (# 31)

5. Strengthen the impeller blades to eliminate the need for the ring (#25)

6. Define or create a safe pathway for the fragments (# 24, 27, 29)

7. Change the principle of operation of the ring, including:

• replace the ring with an airbag that inflates the moment the impeller bursts (# 10) or change its thickness (# 19)

• explode the ring to create a counteracting force (# 20) and/or break the fragments into smaller pieces

8. Replace the impeller with a safer method of providing air (# 2)

Step 1. Select two ideas that resolve the same sub-problem in different ways.

Idea # 17 (Use metal concrete or other composite materials) and idea # 11 (make a thin ring with reinforcing ribs) provide the same function (strengthening) in different ways – changing structure (#17) and changing shape (# 11).

Step 2. Compare these ideas; each has its own advantages.

Idea # 11 is preferable from the main function point of view because it can provide greater strength. However, it is not easy to make ribs from the steel. The advantage of idea # 17 is that composite materials are easy to shape.

Step 3. Consider the idea that has better functional features as the “source of resources”; the other idea is the “recipient of resources.” We select idea # 11 as the “source of resources”

Idea # 17 is the “recipient of resources”

Step 4. Determine the elements that provide better functionality of the “source” idea. The element providing better functionality is a steel tube. Steps 5-7. Apply these elements to the “recipient.” We can combine two ideas having a steel tube with ribs made from a composite material.

According to the checklist, testing the ring can be dangerous itself – for example, reducing the ring’s strength can later produce a ring failure. To avoid this problem, it might be preferable to replace the current test procedure with one that utilizes ultrasound, acoustic emission or other “intro-vision” technologies.

Plan the implementation

The following ideas were suggested for testing:

For the short-term: Ring with hardened surfaces; ring with ribs.

For the mid-term: Explosive ring.

For the long-term: Blades with fibers (wire) inside to keep the fragments in place.

(Part I)

ABSTRACT

One of the most important tasks in robust design is to select an appropriate system output response in the study. The quality of this selection will greatly affect the effectiveness of the robust design project. Currently, this selection process is more like art than science. By using TRIZ and Axiomatic Design principle, several new approaches to enhance robust design are developed. These approaches enable us to select the appropriate system output response in a systematic fashion. The approach described in this paper was successfully applied and verified in a case study in a large automotive company.

Keywords: Axiomatic Design; Robust Design; TRIZ; Basic Function; Ideal Function; S-Field Analysis; Mode of Action.

1. INTRODUCTION

The importance and benefits of performing robust parameter design advocated by G. Taguchi are well known [1] [2] . Many people are familiar with Taguchi’s robust parameter design with such terminologies as ‘orthogonal array’, ‘signal to noise ratio’, ‘control and noise factors’. However, one of the mostly ignored but the most important task for a successful robust parameter design project is to select an appropriate system output characteristic. The identification of a proper output characteristic is a key step to have higher success rate for robust design projects. In order to identify a proper output characteristic, Taguchi suggests the following guidelines (Phadke and Taguchi [2] and Phadke [3] ):

* Identify the ideal function or ideal input/output relationship for the product or process. The quality characteristic should be directly related to the energy transfer associated with the basic mechanism of the product or process.

* Select quality characteristics that are continuous variables, as far as possible.

* Select additive quality characteristics.

* Quality characteristics should be complete. They should cover all dimensions of the ideal function or input/output relationship.

* Quality characteristics should be easy to measure.

According to Taguchi, it is important to avoid using ‘quality symptoms’ such as reliability data, warranty information, scrap and % defective in the late of product development cycle and manufacturing environment, as the output characteristic. Since improving a ‘symptom’ may not be helpful in improving the robustness of system’s ability to deliver its functions, which is really the key objective of a robust design project. Understanding system function, especially basic function, is the key for robust technology development [1] . Defining the ideal state of the basic function, called ideal function, is the centerpiece for identifying output characteristic.

The reason for using an energy-related system output response, according to the discussion of Pahl & Beitz [8] and Hubka [9] , is due to the fact that an engineering system is always designed for delivering its basic function. To deliver its basic function, at least one of the three types of transformation, material, energy and signal transformation (Figure 1) must be used.

Where the details of energy, material and signal include:

• Energy: mechanical, thermal, electrical, chemical… also force, current, heat…

• Material: liquid, gas… also raw material, end product, component…

• Signal: information, data, display, magnitude…

For example, a machining process as an engineering system, the ideal relationship between output and input should be that the output dimensions are exactly same as the intended dimension. This kind of the transformation system is the material transformation. Since energy transformation is a very important type of transformation, and there are many similarities in using these three types of transformation to identify the appropriate output characteristic.

Without loss of generality, energy transformations are used as examples throughout in this paper. Some of the published literature and articles pointed out that energy related characteristic is very helpful to identify proper quality characteristic and should be considered. Nair [4] cites Phadke’s discussion, finding system output response that meets all of these guidelines is sometimes difficult or simply not possible with the technical know-how of the engineers involved. In general, it will be quite challenging to identify system output responses which will meet all of these criteria. Taguchi acknowledges this for fact and states that the use of Taguchi methods will be inefficient to the certain extent if these guidelines are not satisfied. Revelle, Moran and Cox [5] cites Shin Taguchi, Verdun and Wu’s work and point out that the selection of system output response that properly reflects the engineering function of a product or process is the most important and, perhaps, the most difficult task of the quality engineer. The choice of an energyrelated system output response is vital to ensure that the system output response is monotonic. According to Box and Draper [6] , the monotonicity property requires that effects of control factor be both linear and additive. Wasserman [7] , based on the Box and Draper’s study, concludes that from response surface methodology perspective, the requirements of monotonicity property is equivalent to an assumption that the true functional response is purely additive and linear in the region of interest. The reconciliation of Taguchi’s viewpoint is possible based on the assumption that energy-related characteristics are used to ensure that interactions are minimal.

Therefore, identification of the key transformation process is very important to understand and identify the ideal functions of the engineering system. By the choice of a good functional output, there is a good chance of avoiding interactions [2,3] . Without interactions, there is additivity or consistency or reproducibility. Laboratory experiments will be reproduced and research efficiency improved.

However, the above guidelines for selecting appropriate output characteristic are still very conceptual and their implementation is highly dependent on the project leader’s personal experience. There is very little literature shown how a system output response can be designed and selected in a systematic fashion.

This paper will address these shortcomings. With an emphasis on the robustness at the early stages of the product development, the proposed methodology will integrate the concept of Taguchi method with the aid of TRIZ and Axiomatic Design principles. The proposed methodology has the following three mechanisms:

• Definition and identification of different system architectures, inputs/outputs, and ideal function for each of the system/subsystem elements.

• Systematically attempts to facilitate a design that is insensitive to various variations caused by inherent functional interactions or user conditions.

• Bridge gap between robust conceptual design and robust parameter design through proper identification and selection of a system / subsystem output response.

In our paper, section 2 will review Taguchi method, TRIZ and Axiomatic design method. Section 3 will describe our method for selecting output characteristic. Section 4 will discuss the limitation of the method. Section 5 outlines some possible future research, Section 6 is the conclusion section.

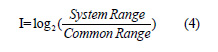

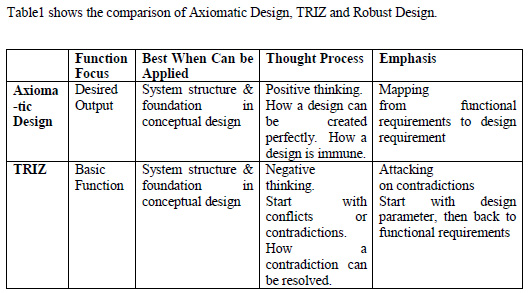

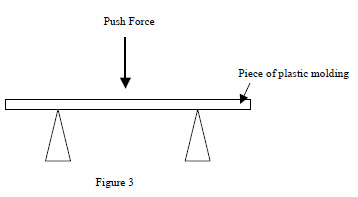

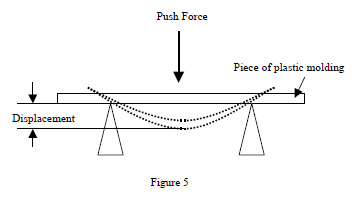

2. REVIEW OF TAGUCHI METHOD, TRIZ AND AXIOMATIC DESIGN

2.1 REVIEW OF TAGUCHI METHOD

Robust design using Taguchi method is an efficient and systematic methodology that applies statistical experimental design for improving product and manufacturing process design. Dr.

Genichi Taguchi’s development of robust design is a great engineering achievement (Clausing 1998) [10] . By 1990, concurrent engineering was becoming widespread in American industry. It brought great improvements. However, the pioneers such as Ford and Xerox were realizing that more was needed. Especially robust design needed to be practiced widely throughout the development of new products and processes.

Taguchi essentially uses the conventional statistical tools, but he simplifies them by identifying a set of stringent guidelines with energy transformation model focused engineering system for experiment layout and analysis of results. Taguchi used and promoted statistical techniques for quality from an engineer’s perspective rather than that of a statistician

As Taguchi’s ideas become more widespread, more and more design engineers use Taguchi’s methodology in their everyday lives. Due to the growing popularity of robust design methods, more and more quality and engineering professionals have shifted their quality paradigm from defect inspecting and problem solving to designing quality and reliability into products or processes.

Taguchi’s approach to design emphasizes continuous improvement and encompasses different aspects of the design process grouped into three main stages:

1. System design. This broadly corresponds to conceptual design in the generalized model of the design process. System design is the conceptual design stage in which scientific and engineering expertise is applied to develop new and original technologies. Robust design using Taguchi method does not focus on the system design stage.

2. Parameter design. Parameter design is the stage at which a selected concept is optimized. Many variables can affect a system function. The variables need to be characterized from an engineering viewpoint. The goals of parameter design are to (1) find that combination of control factors settings that allow the system to achieve its ideal function and (2) remain insensitive to those variables that we cannot control. Parameter design provides opportunities to reduce the product and manufacturing costs.

3. Tolerance design. Although generally considered to be part of the detail design stage, Taguchi views this as a distinct stage to be used when sufficiently small variability cannot be achieved within a parameter design. Initially, tolerances are usually taken to be fairly wide because tight tolerances often incur high supplier or manufacturing costs. Tolerance design can be used to identify those tolerance that, when tightened, produce the most substantial improvement in performance.

Taguchi offers more than techniques of experimental design and analysis. He has a complete and integrated system to develop specifications, engineer the design to specifications, and manufacture the product to specifications. The essence of Taguchi’s approach to “quality by design†is this simple principle-instead of trying to eliminate or reduce the causes for product performance variability, adjust the design of the product so that it can be insensitive to the effects of uncontrolled (noise) variation. The losses incurred to society by the poor product design are quantified using what Taguchi calls â€loss functionâ€, which are assumed to be quadratic in nature. The five principles of Taguchi’s methods are:

1. Select Proper System Output Response

2. Measurement of Function using S/N ratio

3. Take Advantage of Interactions between Control and Noise Factors

4. Use Orthogonal Arrays

5. Two-step Optimization

2.2 REVIEW OF TRIZ

TRIZ is a Russian acronym that stands for the Theory of Inventive Problem Solving originated by Genrikn Altshuller. How can the time required to invent be reduced? How can a process be structured to enhance breakthrough thinking? It was Altshuller’s quest to facilitate the resolution of difficult inventive problems and pass the process for this facilitation on to other people. In trying to answer these questions, Altshuller realized how difficult it is for scientists to think outside their fields of reference, because that involves thinking with a different technology or “language”. In the course of the study of some 400,000 inventions as depicted in patent descriptions, Altshuller noticed a fundamentally consistent approach used by the best inventors to solve problems. At the heart of the best solutions, as described by the patents, existed an engineering conflict, or a “contradiction.” The best inventions consistently solved conflicts without compromise. Upon closer examination and classification of innovative solutions, natural patterns of solutions started to emerge. Altshuller had discovered that when an engineering system was reduced to reveal the essential system contradictions, inventive solutions eliminated the contradictions completely. Furthermore, Altshuller noticed that the same inventive solutions appeared repeatedly at different points in time and in different places.

2.2.1 SUBSTANCE FIELD ANALYSIS

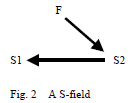

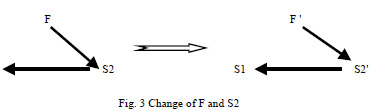

1. Substance-field analysis is a TRIZ analytical tool for modeling problems related to existing technological system. Substance-field is a model of minimal, functioning and controllable technical system [11] . Every system is created to perform some functions. The desired function is the output from an object or substance (S1), caused by another object (S2) with the help of some means (types of energy, F). The general term, substance has been used in the classical TRIZ literature to refer to some object. Substances are objects of any level of complexity. They can be single items or complex systems. The action or means of accomplishing the action is called a field. Within the database of patents, there are 76 standard substance-field solutions permit the quick modeling of simple structures for substance-field analysis. If there is a problem with an existing system and any of the three elements are missing, substance-field analysis indicates where the model requires completion and offers directions for innovative thinking. In short, substance-Field Analysis- S-F analysis is a technique used to model an engineering problem. S-F analysis looks at the interaction between substances and fields (energy) to describe the situation in a common language. In cases where the engineering system is not performing adequately, the S-F model leads the problem solver to standard solutions to help converge on an improvement. There are four steps to follow in making the Substance-field model [12] and:

i. Identify the elements.

ii. Construct the model.

iii. Consider solutions from the 76 standard solutions

iv. Develop a concept to support the solution.

2.2.2 OTHER TRIZ Tools, Strategies, and Methods

TRIZ innovative process consists of two parts: the analytical stage and the synthesis stage. A basic description of some of the instruments/tools is as follows:

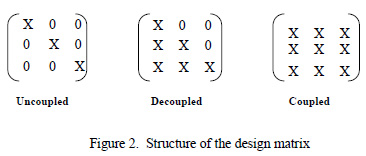

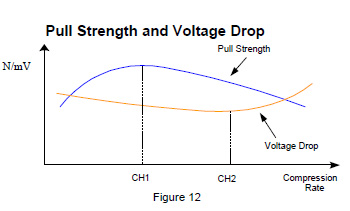

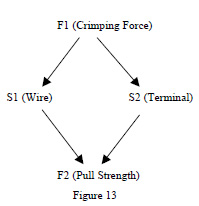

1 Ideality Concept-Every system performs functions which generate useful and harmful effects. Useful effects are the desirable functions of the system, while harmful effects are the undesirable effects of the system. When solving problems, one of the goals is to maximize the useful functions of a system. The ideality concept has two main purposes. First it is a law that all engineering systems evolve to increasing degrees of ideality. Second, it tries to get the problem solver to conceptualize perfection and helps break out of psychological inertia or paradigms.