Student’s Corner #4 - Miracle Of Corrugation

Editor | On 20, Apr 2006

Edited by: Leora C. Slocum*, Micaiah C. Slocum (13), and Hosannah M. Slocum (11)

(*contact at leora@slocumfamily.org)

Can you believe that an invention can “jump†into life from a simple sheet of paper? If not, read the following text, and try some experiments. We are sure that you’ll get excellent inventing ideas.

First, try to answer this simple question: Could a sheet of paper, for example, a file folder, support 5 pounds or even more? Most people would say, “Noâ€. Now follow up with a simple experiment. Fold a file folder to get an accordion like structure. Then put this “accordion†on two supports, separated by enough big distance, and put a 5-pound metal plate (or similar object with a similar weight) on these supports. You can see the results of this experiment in Fig.1. To be more sure in the results, put additional weight on top of the metal plate. You can use something like a toy tractor-loader. Can you see any deformation (shape change) of this accordion. We are sure that the paper structure won’t bend or wiggle.

Fig.1. Scheme of an Experiment with Accordion-like

Folded Paper.

Courtesy of Motiar Ruhman.

Now we propose members of our Student’s Corner provide some experiments with this accordion-like paper sheets. Try different types of paper; different length, width and thickness of paper, length of horizontal air gap between two vertical supports, and vary any other parameters of this system. It could be your first Inventive Science Project, which would be helpful in your future career as an inventor. Accordion-like structures and other structures based on folded materials, including paper, steel, etc. are corrugated or use the “Miracle of Corrugationâ€! Even in nature we can find structures corrugated in different ways, not only accordion-like. In Fig 2 you can see an exiting application of the corrugation principle in nature.

Look at of Fig.2b of Royal Water Lily (Victoria Amazonica). Could such a floating flower support a girl?

Fig.2. Royal Water Lily

a –Empty; b – with child

Courtesy of Igor Endovtsev

In an extremely interesting book “Nature – Mother of Inventionâ€, written by Felix Patury, you can find a picture of a bigger girl, who weighs 90 pounds! What we can conclude from these pictures is that the rim on the circumference of the water lily provides a reinforcing structure. Also in the Fig. 2b you can recognize radial pleats or folds, which provide corrugation of the circle.

Both above cases, accordion-like folded sheets of paper and water lillies with rims and radial pleats, are examples of reinforced structures. Below we’ll show some more corrugated structures. The majority of people know corrugated structures by corrugated cardboard boxes, some examples of which are illustrated below.

Fig. 3. Examples of Corrugated

a – corrugated cardboard box; b – corrugated panel.

Courtesy of Igor Endovtsev.

Fig.3a shows a cardboard box, one of the earliest applications of corrugated structures. The internal structure of corrugation panels, which makes the box strong, is shown in Fig.3b. The strength of the corrugated cardboard makes it perfect for transportation of goods; and corrugated boxes are used by the U.S. Post Office as reliable tools for different applications.

Did you notice a problem while observing the cardboard box in Fig. 3a? – How does one combine the top parts of the box to make a reliable “locking†cover it? One solution could be the use of origami.

In 1886, the City Engineer in Crawfordsville, Indiana stopped at the local drug store on his way home after a day designing a new storm sewer. As E. Stanley Simpson watched the store proprietor wrap a bottle of medicine in a piece of corrugated cardboard, the thought struck him to try the same process with metal to replace massive drainage structures utilized at that time. Simpson enlisted a local sheet metal operator to assist him and they jointly perfected the design for a culvert made from corrugated metal sheets. The patent was issued May 5, 1896, and the steel pipe drainage industry was born. An example of contemporary corrugated drainage pipe is shown in Fig.4.

Fig.4. Corrugated Drainage Pipe (a) and Cross Section of the Wall.

Courtesy of Igor Endovtsev.

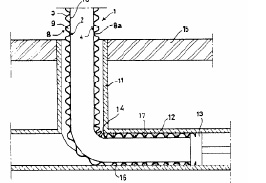

Corrugated pipes are very effective for relining deteriorated pipelines, because they are flexible; its external surface, due to its flexibility, could be adjusted to the internal surface of pipe-liner. Moreover, 3-D flexibility of corrugated pipe-liner allows its insertion through a manhole. Such technology is illustrated by Fig. 5. A plastic pipe, consisting of an outer corrugated plastic pipe, and an inner smooth wall, consisting of a wear resistant elastomer, are heat welded to each other. The cavities between the inner pipe and the corrugations may be filled with a foam plastic. This plastic pipe is used for repairing or renewing a sewage pipe by installing such a pipe from a vertical shaft of the sewage system into the sewage pipes. The gaps between the outer side of the corrugation and the inner side of the sewage pipe may be filled with a mortar.

Fig. 5. Relining an underground conduit

with corrugated liner

Public Domain – US Patent # 4,754,781

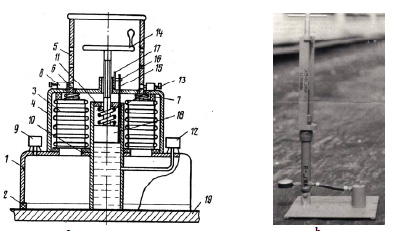

Flexible corrugated pipe may also be used to measure water permeability of waterprotective structures. The scheme of this device is illustrated in Fig. 6-b, and a general look is shown in Fig. 6-b.

Fig.6 Device for testing water permeability

water insulation materials

a – scheme; b- general look

Public Domain – SU Patent #1295245

1 -vacuum camera; 2 –elastic element; 3 – corrugated camera (silphon);

4- case; 5 – pressing; 6- spring; 7- gasket; 8 – stopper; 9 – vacuum-gauge;

10 – cylinder; 11 – rod; 12 – plunger; 13 – spring; 14 – driver; 15 – pipe;

16 – faucet; 17 – strap; 18 – manometer.

To measure the permeability of materials, the gauge is installed on the surface, as shown in the Fig.6-b, and secured. Then the siphon is pressed down, pressing air out and causing a vacuum. This vacuum is the anchoring device to the surface under control. The water fills cylinder 10 by faucet 16 through pipe 15. Water pressure can be increased to the required level by closing faucet 16 and rotating driver 14. If the water level is stable during the required time, the insulation meets the quality requirements. Otherwise, it needs repairing. In this example, a corrugated structure (siphon) fulfils the function of a pump, due to its ability to deformation.

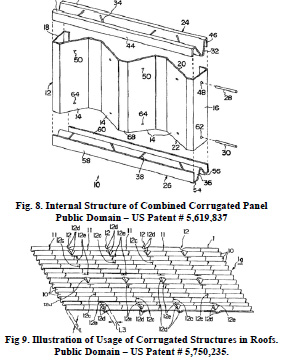

An analysis of the internal structure of corrugated systems is shown in Figs. 6-8, in which structures of different corrugated systems are illustrated.

Fig.7. Example of Water Resistant Corrugated Panel.

Public Domain – US Patent #5,698,295.

In Fig. 7, a corrugated panel is shown before its parts are combined. The whole structure is then placed inside a flexible hose to make it waterproof.

Usage of corrugated boards in roof structures is shown below in the Fig. 10.

Fig.10. Corrugated Roof on one of the Buildings

of Lugansk Railway Station (Ukraine)

Courtesy of Igor Endovtsev

We hope that you, the members of our Student’s Corner, will use the corrugation principle to solve problems you come across in life and share what you have learned with us. We are very interested in the results of your experiments, like shown in Fig.1. To peak your interest in inventiving, look at the picture below, and try to recognize the structure of another miracle. We will discuss this miracle in our next Student’s Corner.

Fig.10.

Courtesy of Igor Endovtsev

Happy Inventing!

Corrugated Paper Experiment

by Hosannah Slocum, age 11

After reading the Student Corner about the Miracle of Corrugation, I did some experiments to test the difference between corrugated paper and regular paper.

First, I made a small sheet of corrugated paper by folding a piece of regular college notebook paper many times horizontally. I glued one sheet of paper to the bottom and another to the top to give it a bottom layer and a top layer that held the corrugation together. Then I set up some books to use for supports. I made it so all four sides of the paper would be on the books but not the middle. I took a few small objects of different weights, like a small brass figurine and a small horseshoe magnet, and put them on the corrugated paper. None of the objects fell through. I also tried moving the books further apart to see how big the area of nonsupported corrugated paper could be before it fell. I was surprised that I could move the books almost all the way to the edge before the paper fell. Then I did the same experiments with a normal sheet of paper. Most of the objects fell through and I had to keep the books close together to keep the paper from falling. I enjoyed testing the theory I learned about in the Student Corner this month. I hope I can do some more experiments soon!

Editorial staff for this article: Leora, Micaiah (13), and Hosannah (11) Slocum. The Slocum Family is pleased to be involved with The TRIZ Journal and have incorporated these editorial activities into their home school education program.