Rapid Innovation with TRIZ - Part 2 - Using TRIZ symbols and schematics in continuous innovation

Editor | On 26, Jul 2005

By: Shahid S. Ahmed PhD

shahid@technoserve.com.au

Abstract:

A system of symbols representing classical TRIZ tools and methods is proposed.

These basic symbols can be used in schematic diagrams which provide a time and utility context to the continuous innovation process. The representation of dialectic chains by a schematics based approach has several advantages in the processing of complex innovation activities. These schematics provide a visual record of the reasoning employed in reaching successive levels in the innovation program.

It is also proposed that the symbols + schematic approach can serve as a workable first step in linking TRIZ with systems engineering tools for problem solving. The rationale for the adoption of standard engineering tools and practices in conjunction with TRIZ is to explore directions for the further evolution and convergence of the latter within the technology mainstream.

Introduction:

As a collection of thinking tools, TRIZ is at heart a codified abstraction of best practice in inventive problem solving whose scope of application is mostly in the engineering and technology domains. This is a strong bond – it is frequently demonstrated that most engineering and technology innovations can be described in the context of TRIZ principles. For this bond to grow even stronger, we need to visualise a scenario where the tool and the domain have a high degree of overlap.

We begin to look further at this goal of greater commonality by investigating some of the simpler and more general methods in the standard engineering toolbox. Our aim is to adopt suitable methods for use with TRIZ. One such method is the engineering schematic drawing.

The key difference between an engineering schematic and an innovation activity is the element of time. The schematic represents essentially a static view of the system where the components of the system do not change their form or function over time. In an innovation process, however, we expect each successive stage of the program to yield outcomes that have greater utility than the previous one and continually approach a higher form of ideality. As a result we expect that some change in form or function will surely take place as a result of the continual innovation.

A previous paper “Rapid Innovation with TRIZ – A Case Study in Continuous Product Development†[TRIZ-Journal, June 2005] described an application of TRIZ principles to the case of an automobile colliding with a utility pole at high speed and came up with a series of inventive solutions in the form of nine dialectics. The term “dialectic” was used to signify a distinct module of innovation activity that leads to an improvement in the solvability of the problem. The term “dialectic chaining” was used to signify the linking of such modules in an evolutionary sense. This paper continues with that same case study by discussing the above mentioned approach in that context.

Static vs. dynamic schematics:

The dialectic or modular representation of the innovation process allows us to introduce a time context in the overall scheme. Since each dialectic represents a static snapshot (in time) of the innovation activity, we are able to use the TRIZ symbols within this static representation, just as standard symbols are used in an engineering schematic. A symbol provides visual clues as to the functionality and inter-relationships of components. The workings of fairly complex technical systems can be quickly understood by studying their schematics, and for this no other comparable substitute exists.

The dynamic view of the innovation process is provided by linking block representations of these static snapshots in time and this, in effect, becomes the dialectic chain. Here the emphasis shifts from showing details of the interactions within , and switches to a more systems like approach. We are interested, for instance, in displaying the gain in utility as a result of each innovation activity. We would also like to see how far along we are on the planned time horizon and be able to re-assign priorities to critical tasks.

We can take a stepped approach towards this task. The first step is to come up with representative symbols of standard TRIZ techniques. The second step is to describe the modularised nature of the innovative process as a dialectic chain. The third step is to examine constraints on the dialectic chain and devise methods of managing these constraints. This paper will only focus on the first step with a brief mention of dialectic chains. Some thoughts on the processing of constraints and bounds in dialectic chains and using derivatives of the Ideal Final Result as additional directions of solution will be presented in a following paper.

Step One: Defining the TRIZ symbols

Symbols are simple signs that represent the features, characteristics or unique attributes of a component or the relationship between components. It is preferable to have the symbol correspond with our intuition as to what is note-worthy or unique in an item of interest.

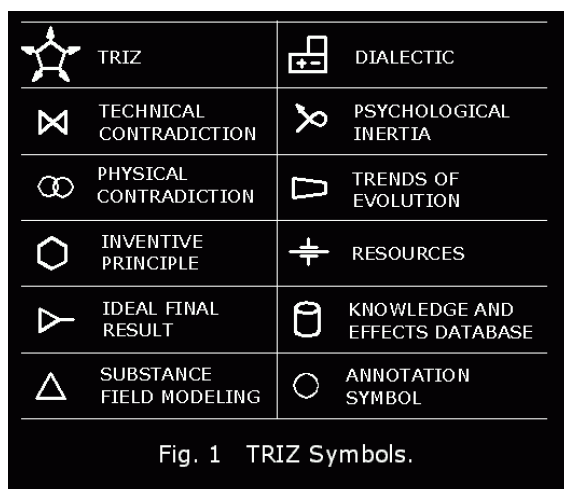

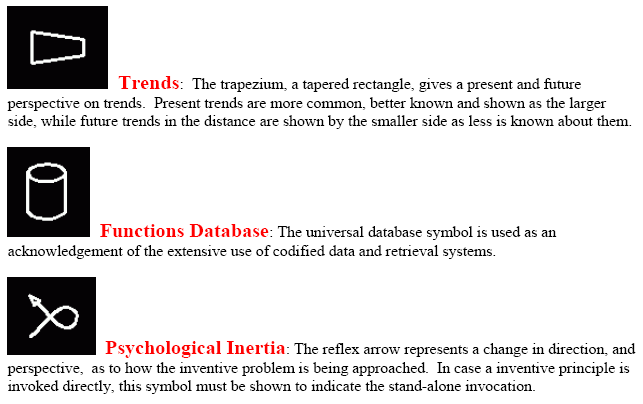

Figure 1 provides a table of the proposed symbols.

TRIZ: A pentagon with 5 short arrows at each vertex. Optionally, the letters “TRIZ†contained within. The symbol represents the growing influence of TRIZ based on its five essential components:

TRIZ: A pentagon with 5 short arrows at each vertex. Optionally, the letters “TRIZ†contained within. The symbol represents the growing influence of TRIZ based on its five essential components:

1. ARIZ (including psychological inertia tools, IFR, resources, problem clarification tools).

2. Contradictions (both technical and physical, if found in any technical system).

3. Systems modelling (Su-Field modelling, functional analysis).

4. Trends of evolution (trends for systems and for component design parameters).

5. Knowledge databases (scientific effects, international patent pools)

The presence of the TRIZ symbol on or near the title block of an engineering drawing or schematic would indicate the use of TRIZ symbols alongside the standard technical symbols and representations.

Using the TRIZ symbols:

All well-known works in applied and structured innovation, and particularly TRIZ and USIT, strongly recommend the use of pictorial sketches and diagrams at all stages of the process. The reader may refer to standard works by Altshuller [GA00] , Mann [DM02] , Salamatov [YS00] , and Sickafus [ES97] , to appreciate the emphasis placed on diagramming and pictorial representations. With software based innovation packages such as CREAX, we again see strong importance being placed on sketching as part of their integrated methodology [CR03] .

1. At the very basic level, TRIZ symbols allow an enhancement of the sketch by providing for an convenient way to pictorially link the tools to the task. This allows us to discern, with a quick glance, the tools (TRIZ methods, inventive principles, IFR, resources, trends, etc.) used as we progress from one basic step of the task to the next.

2. By using TRIZ symbols with the dialectic chain representation, we can obtain a structured view of the overall inventive process in the context of time.

3. TRIZ symbols also provide a means of compiling data on the relative frequency of usage of the tools and allows us to draw inferences as to any possible correlation with the type and nature of inventive task within the organisation.

Step Two: Describing a dialectic chain (DC):

Each separate innovation program in the organisation can be considered, from start to finish, as a series of modular innovation efforts, termed dialectics. Every dialectic builds on the gains of the previous. Thus for any innovation program, such as modifications to an existing manufacturing process or a new product development, we can focus on the entirety of the program as a linked chain of dialectics. It is important to note that it may take several attempts, and therefore several separate dialectic chains or paths, before the desired level of utility is achieved in an innovation program. Each dialectic chain therefore represents a path from the initial conditions to either success or failure. Both types of outcomes are vital and need to be preserved as part of the innovation repository of the organisation.

A dialectic chain can be described at the macro- and micro- levels. We may term these as the ‘chain view’ (CV) and the ‘dialectic view’ (DV), respectively. At the macro level, we are concerned with the overall progress of the innovation program in the context of time and the required utility. The chain is shown in the CV by linking blocked representations of individual dialectics against the time (abscissa, X) and required utility (ordinate, Y) axis, as shown in Fig. 2.

Describing the dialectic view:

The micro level, on the other hand, is when we need to focus on the internal details within each link of the dialectic chain. We call this micro-level representation the dialectic view or DV. It is in the DV that the above proposed TRIZ symbols are mostly used.

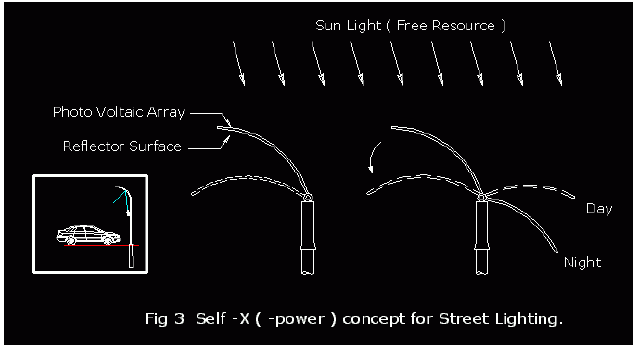

Each DV is based around a drawing or clear sketch of the inventive problem, which happens to be the dialectic under review. We clearly specify the gains from the previous dialectic, the boundary conditions for the present dialectic and the outcomes required. A much simplified representation of a DV is shown in Fig. 4. It is based on the 8th dialectic dealing with Self-X in the car-pole problem, as shown in Fig. 3 below.

A quick look at the DV in Fig. 4 will show that there are five separate annotations in circles, labelled 1 to 5. Of these three represent use of available resources, one a resolved technical contradiction and one a resolved physical contradiction. Three inventive principles were used.

With some familiarity with the symbols, we can quickly observe the use of TRIZ tools in the processing of the dialectic. Circled annotation 1 refers to an earlier dialectic, D3, where the tensile strength of an aluminium pole was an issue and was processed as an physical contradiction.

Inventive principles P1 – Segmentation, and P2 – Extraction were used as is shown by the symbols for inventive principles. Annotation 2 deals with the processing of a technical contradiction whose outcome was inventive principle 8 – Counterbalance. Additional panels were added to counter the weight of the original PV panels.

Annotation 3 indicates the height of the pole being used as a free resource to obtain maximum sunlight. Annotation 4 points to the availability of sunlight as a free resource. Annotation 5 points to another available resource, the stepper motor or positioner which provides a positioning capability to the reflector. Since this capability is available and unused during the day, we are able to utilise it as such.

Further developments:

In this article, we have limited our focus to the first step of defining TRIZ symbols. The second and third steps are perhaps more interesting as we examine a dialectic chain and means of managing innovation constraints through this approach.

We would like the dialectic chain approach to provide us with answers to the following questions:

1. How do we measure the output or gain in utility from a dialectic?

2. How do we assess the status of an ongoing innovation program?

3. How do we measure time-critical activities and re-assess priorities? What types of resources can be applied to critical activities?

4. What has been the history and trends of usage of TRIZ tools in the organisation? Is there a correlation between the nature of problems and the tools used for their solution?

5. What is the personal preference or tendency of a user in deploying TRIZ tools?

6. Can the Ideal Final Result help us come up with multiple dialectic chains for the same innovation task?

Conclusion:

The paper proposes a set of simple and intuitive TRIZ symbols. These can be used to enhance either hand-drawn sketches or CAD diagrams commonly used in the innovation process. Some users of TRIZ may find standard symbols helpful in quickly understanding the reasoning deployed elsewhere, for instance in a collaborative innovation program.

It is also proposed that the symbols + schematic approach can serve as a workable first step in linking TRIZ with systems engineering tools for problem solving. The dialectic chain approach is suggested to provide both the static, detailed view as well as the dynamic, overall view of the innovative process. Further details of the latter will be presented in a forthcoming article.

Acknowledgement:

The author wishes to express his thanks to Dr. Ellen Domb for her support.

References:

[CR03] CREAX Innovation Suite 3.1, CREAX, Ieper, Belgium, 2003.

[DM02] Mann, D., “Hands On Systematic Innovation”, CREAX n.v., Belgium, 2002.

[ES97] Sickafus, E., “Unified Structured Innovative Thinking”, NTELLECK, MI, USA, 1997

[GA00] Altshuller, G., “The Innovation Algorithm”, Technical Innovation Center, MA, USA, 2000.

[YS00] Salamatov, Y., “TRIZ: The Right Solution at the Right Time”, Insytec B.V., The Netherlands, 2000.