A Macro Process Model for Product Innovation Using TRIZ

Editor | On 18, Sep 2005

By: Tan Runhua

(rhtan@hebut.edu.cn)

(Design Institute for Innovation, Hebei University of Technology, Tianjin, 300130, China)

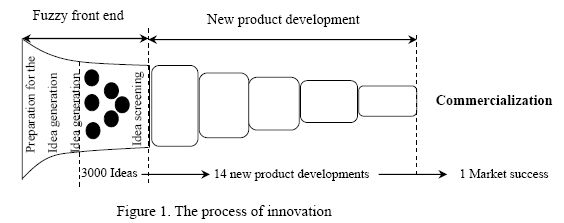

Abstract: The process of product innovation consists of three stages, which are fuzzy front end (FFE), new product development (NPD) and commercialization (COM). Theory of inventive problem solving (TRIZ) is a systematic approach to find innovative solutions for technical problems.

The patterns and lines of TRIZ are applied to FFE to produce new ideas. The principles, standard solutions and effects of TRIZ are applied to develop concepts. The principles are applied to solve contradictions in both design and manufacture in NPD. A new macro-process model for product innovation is formed under an environment of digital technologies which a company has.

1 Introduction

Contrary to ancient myths, successful innovation does not depend on a flash of inspiration, the lightbulb going on over the inventor’s head . Following models of innovation step by step is key factor for success. The process of innovation is divided into three sub-process, fuzzy front end (FFE), new product development (NPD) and commercialization. Many researchers have developed several models for a sub-process or the whole process of innovation in the past years.

Rothwell developed models for five generation innovation process from the developing history of manufacturing companies. Goldenberg et al found five patterns for innovation in the point of view for improving the existing products. There are several models for FFE. Kochhar and Williems describe a reference model, which can be used for the management of the FFE of the new product introduction process. Khurana and Rosenthal also present a model for FFE. The model of Koen et al. is called new concept development model (NCD). P&B’s model of comprehensive design methodology and Suh’s model of axiomatic design [9] are famous for product design. Innovation and its sub-process are very complex in practice. There is no a single best model known in the world now which can guide all the activities for innovation of different kind of companies. New models of more suitable, more flexible, or more specific are general research topics.

Theory of inventive problem solving (TRIZ) was developed by Altshuller in USSR and now is used in solving inventive problems of companies by many companies in the world. In this research, TRIZ is applied to innovation and form a macro process model for all the activities of innovation.

2 Innovation Process

The process of innovation is divided into three sub-process, FFE, NPD and commercialization, as shown in Figure 1. FFE is the front phase of the process which deal with new ideas for innovations, takes place directly before the new product development (NPD). NDP includes all aspects, such as product design and manufacture processes. Commercialization makes profits for companies from the outputs of NPD, which are the new products of NPD. And Fig. 1 also shows that the number of ideas decreases quickly throughout the various steps of the innovation process.

Of 3000 ideas generated, only 14 new product development projects are initiated and of 1.7 market launches only one successful product idea will survive up to market launch.

they are put into the market M1 and M2 and make profits for the company. Based on P1 and P11, alternative products P2, P3 and P12 are produced and are put into the market M1, M3 and M4. Based on T1 and T11, alternative technologies T2 and T12 are formed and together with products P3 and P12 a new product P21 is produced. P21 is not only put into the new market M5 but also put into the old market M4.

A model is a kind of abstraction for reality. A process model for innovation should describe the main activities and the relationship among them. The main activities in a process of innovation should include idea generation, concept development and solving contradictions. They are discussed in the following.

3 Idea Generation From Market

New market space is a source of idea generation. Companies often wish to find some better alternatives to their products in order to help them break free from the competition in the world market. The world market is the biggest opportunity of innovation for any company. The new ideas can be imported directly from another company of the world. The new ideas produced in a company can be exported to another company, which can help the company-self to do the best. Economic development always implies some big projects, such as “transport the natural gas from the west to the east of Chinaâ€. They imply some opportunities for companies, such as the companies to produce steel pipes and valves in big diameters, to make innovation and sell their products to the projects. The needs of human change from low level to high level: physiological, safety, social, esteem and self-actualisation. Transformation from low level to high level of needs means opportunities for companies. For example, many persons will buy cars of different kinds in the following a few years because they have enough money to do so in China. The companies should produce cars of different kinds to meet the potential needs.

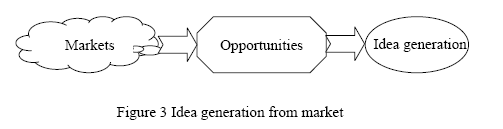

The market is equally available to every company. Some will fine new market space for their products but others can not. Many researchers have detected the patterns in companies who successfully create new markets. Based on these researches, Chan and Renee[13] have listed six basic approaches to create market spaces, which can help companies to expand market space. They are substitute industries, strategic groups within industries, chain of buyers, complementary product and service offerings, the functional or emotional appeal to buyers, time. From the new space some opportunities can be identified and ideas for new products can also be produced. Figure 3 shows the process of idea generation from markets. It is a process of market pull, in which opportunities come from different markets.

4 Idea Generation Using TRIZ

Patterns and lines of technological evolution belong to technological forecasting of TRIZ [1] , which is a proactive approach to forecasting developed during the 1970s and now is also in development. Technological Forecasting reports the probabilities of certain design parameters falling within particular confidence intervals at some future time. Critical design advances for future products and processes can be identified by applying the patterns and lines. With these advances, the field of parameters is narrowed and a tighter range for confidence levels is defined. There are 8 patterns and many lines under each pattern for the use of technological forecasting.

Eight patterns are as following:

*Stages of Evolution

*Evolution Toward Increased Ideality

* Non-Uniform Development of System Elements

*Evolution Toward Increased Dynamism and Controllability

* Evolution Toward Increased Complexity and then Simplification

*Evolution with Matching and Mismatching Elements

*Evolution Toward the Micro-Level and Increased Use of Fields

*Evolution Toward Decreased Human Involvement

Fig. 4 is a line under pattern: Evolution Toward Increased Dynamism and Controllability.

There are seven states shown in this line which are stiff system, one joint, many joints, elastomer, liquid, gas and field. The beginning state for this line is stiff system and the ending state is field.

The experiences of application of lines show the several new ideas are implied in the states of the lines. The line shown in Fig. 4 is analyzed as an example. If the technology of the product under study is in the state of “many jointâ€, the future states of technology evolution may be elastomer, liquid, gas, or field. Every future state may imply one or a few ideas for the future development of the technology. From the line a technology opportunity can be found and several new ideas can also be generated.

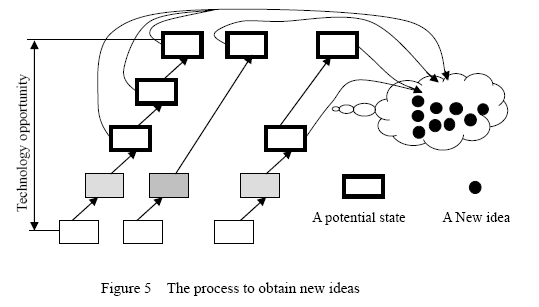

Technology opportunities for the existing product under study can be found by searching different patterns and lines of evolution. First, a pattern is selected and a line under this pattern is also selected. Then, current state for the product is determined from the line selected. The distance between the ending state and the current state in that line is a technology opportunity. By above searching method one or a few technology opportunities can be determined.

Every technology opportunity includes one or several potential states, which are upper states from the current to the ending state. Every potential state implies one or a few new ideas of potential technologies to be used for the evolution of current technology in the future development.

Fig. 5 shows the process to obtain new ideas from the technology opportunities selected.

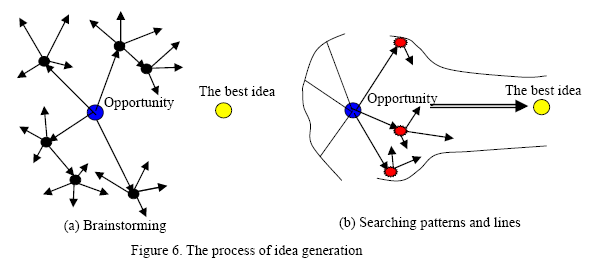

From an opportunity many ideas may be generated by brainstorming, which is shown in Fig.

6(a). Some searching directions and redundant ideas are filtered using patterns and lines of TRIZ in Fig. 6(b). The fewer ideas are generated by searching patterns and lines but these ideas are near the best idea. So uncertainty for the ideas, which belongs to technological uncertainty, is reduced. Generally speaking, the best idea is difficult to find and a suitable one is the searching result.

Figure 7 shows the process of idea generation using TRIZ. It is a process of technical push.

The opportunities come from the patterns and lines of TRIZ. Every evolution line has one or more potential states, which form opportunities.

5 Concept Development Using TRIZ

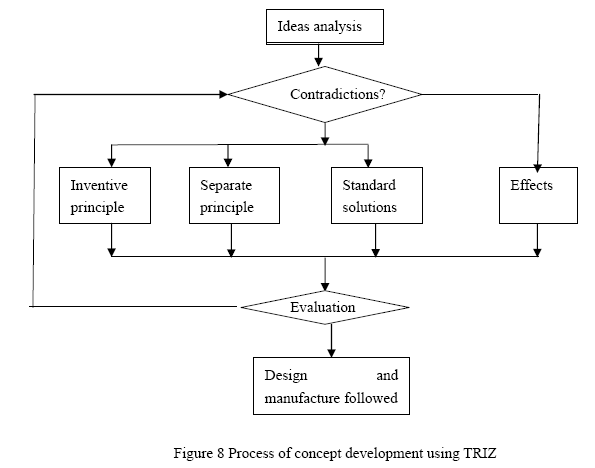

The patterns and lines of technology system evolution are helpful in identification of new ideas, but which are not specific concepts of next-generation technologies. Concept development for the next-generation technologies should be carried out after the ideas are produced. There are

two kinds of problems to be solved for concept development, which are as following:

*The transition from one stage of evolution to a higher stage creates at lest a technical or physical contradiction. The next-generation invention cannot be fully developed unless theses system contradictions are resolved.

*The high-potential direction or ideas for the next-generation invention are recognized but the physics to realize that direction are missing.

The tools of TRIZ: inventive principles, standard solutions and effects are helpful to apply into these situations. Figure 8 shows this. The ideas are analyzed first and decisions then should be made. If contradictions do exist the inventive principles or standard solutions are chosen in order to solve them. If there is no contradiction, which means that the physics to realize the ideas are missing, effects should be selected. The new concepts developed are evaluated. If one or two concepts are accepted they are input into the following design and manufacture process, or otherwise it should be returned to the idea analysis again.

There are two kinds of inventive principles for solving technical contradictions and physical contradictions. 39 engineering parameters and a matrix are used to select a few from 40 principles, which are relevant to solve a specific contradiction. There are four separation principles to solve physical contradictions. They are selected according to space, time, condition or parts and whole.

There are 75 standard solutions in TRIZ, which are divided into 5 classes. First, Substance-field models for the problem to be solved are developed. Then, a standard solution from the class1 to class 4 is selected by the Su-field model and to obtain a pre-solution. The class 5 is last be used to modify the pre-solution and the final solution is obtained.

Effects in TRIZ are helpful to make physics or working principles to realize the ideas produced in FFE. There are about 10,000 effects described in sciences, such as physics, mathematics, chemical, etc. Some of them may be used in the determination of the working principles in product design. An ordinary engineer usually knows about 100 effects. So a data base of effects is a kind of assistant tool for product designers. Some computer-aided innovation(CAI) software are needed as a tool or assistance.

Some CAI system have been developed such as, Techoptimizer[14] and InventionTool[15] .

They include data-base for evolution, principles, standard solutions and effects. Many companies in the developed world has applied them, for example GM, MADMAX, DARPA, UScom, REVEO,et al. They made benefits from the application.

6 Solving Contradictions of down Stream

After concept development the following sub-process for innovation is called down stream in this research, which includes embodiment and detailed design, manufacturing and sales. There are also some difficult problems to be solved in this sub-process, which imply the existence of contradictions. TRIZ is specific or stronger to solve them.

Bariani et al [16] combine TRIZ with DFMA (Design for manufacture and assembly) to reduce machine elements of a satellite antenna. The principles of TRIZ: local quality, flexible shell and thin film are used in their example. Mao and Tesng[17] apply TRIZ to produce a new concept of a piston reactor for bicycle hydraulic disc braking system. The principles of TRIZ: segmentation, mechanical vibration are used to solve the contradiction in their work. Edgardo et al [18] of Volkswagen of Mexico S.A. de C.V, a well-known German automotive industry, use TRIZ to solve contradictions of manufacturing process of steering knuckle, which is an important machine element for a car. These are all examples to apply TRIZ to solve contradictions for structure simplication or manufacture.

As to the sales, there are no research results for this field in TRIZ Journal [12] . But there are some research results for management using TRIZ in that journal. In the future there may be some results because the principles of TRIZ can also be applied to solve contradictions of sales.

7 A Macro Process Model For Innovation

There is a time/cost trade off or contradiction for innovation, in which development time is shortened but the development cost is increased. The relationship between development time and cost is like a U-shape as shown in figure 9 [3] . Rothwell [3] identified twenty-four factors in increasing development speed or efficiency or both. One factor is the use of CAD systems which

can increase development speed and efficiency while at the same time ensuring optimum manufacturability. Dodgson [19] suggested that the innovation process can be intensified as a result of the application of new digital technologies. The digital technologies used in innovation process are shown in table 1[19] . In many companies of developed counties, some technologies, such as six sigma and TRIZ are applied to increase the speed and reduce the cost for innovation.

In China, many companies have applied some technologies listed in table 1, such as CAD/CAM, CAE, PDM, ERP. But TRIZ is seldom applied up to now for some reasons, such as no designers really understand the meaning of TRIZ and no consulting agencies of TRIZ in China.

There will be some applications of TRIZ in China companies in the following a few years for the following reasons:

*Some universities in China begin to the course of TRIZ for under and post graduate students.

*Some companies begin to make short training about TRIZ for their designers.

* The first commercial CAI system of TRIZ called InventionTool2.0 in China has been developed.

*Innovation is becoming the most important activities then ever before for the successful competition of companies.

* The product development relying on experiences should be transferred to a systematic process guided by theories.

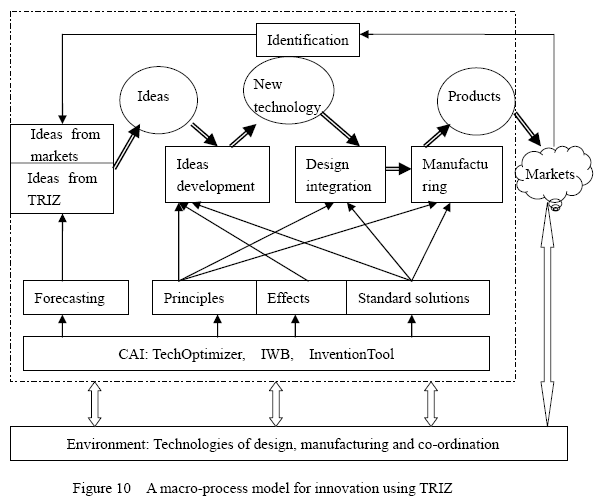

The core of innovation is to find difficult problems, such as the problems with contradictions, and to solve them quickly. The TRIZ is not only a specific technology for innovation but also the technology for software development of CAI. But successful innovation should be carried out in a environment of digital technologies in table 1. If a company has an environment of this kind a process model to apply TRIZ is also needed, especially for the companies of China. Figure 10 is a macro model of this kind.

The model of figure 10 has two parts, innovation core and environment. The environment is all the digital technologies applied in a companies and market. The core is a process model based on TRIZ for product development. The supporting digital technology for the core is CAI. The idea generation in the core is a fusion of market opportunities, pattern, lines and the state of technologies in the lines, capability of the company. The idea development is supported by principles/effects/standard solutions. Design integration of configuration and manufacture are supported by environment but if there is any contradictions the principles of TRIZ can be used. Under the application of this model the designers with some knowledge of TRIZ of a company will increase the speed of product development and reduce the cost at same time.

8 Conclusions

The core of innovation is to find problems and solve them. TRIZ is specific for finding problems and solving contradictions. The patterns and lines of TRIZ are applied to forecast the evolution of technologies. The principles, effects and standard solutions are applied to concept development and design and manufacturing. CAI based on TRIZ include data-base for innovation.

In the environment that a company has a macro process model for innovation is then formed.

The model is only a macro level. How to fuse the CAI with the environment is a problem needed to be solved.

Designers of companies, especial that of China, to understand the meaning of TRIZ, are important factor to apply this model. Mass training program is needed for them in order to increase the competitive ability of theses companies.

Acknowledgment

The research is supported in part by Natural Science Foundation of China under Grant Numbers 50375045 and Tianjin Natural Science Foundation key projects (043802211). No part of this paper represents the views and opinions of any of the sponsors mentioned above.

References

1 Clausing D and Fey V, Effective innovation, ASME, New York, 2004

2 Stevens G A, Berley J, 2003 Piloting the rocket of radical innovation, Research Technology Management 2003; 46(March-April):16-25

3 Rothwell R, Towards the fifth-generation innovation process, International Marketing Review, 1994, 11(1):7-31

4 Goldenberg J, Horowits R, Levav A, Finding your innovation sweet spot, Harvard business review, 2003, 81(3):120-129

5 Kochhar A K, Williams M, Modeling the front end of the new product introduction process for rapid product development track – product and process design, Proceedings of the Twelfth Annual Conference of the Production and Operations Management Society, Orlando,Fl,2001

6 Khurana A, Rosenthal S R, Integrating the fuzzy front end of new product development, Sloan Management Review 1997; 103-120

7 Koen, P., Ajamian, G., Burkart, R., et al, Providing Clarity and a Common Language to The “Fuzzy Front End”, Research Technology Management 2001; (March-April) : 46-55

8 Pahl G, Beitz W, Engineering design – a systematic approach, The 2nd Edition, London, Springer-Verlag, 2000

9 Suh N P, Axiomatic design – advances and applications, New York: Oxford University Press, 2001

10 Altshuller G, The Innovation Algorithm, TRIZ, Systematic Innovation and Technical creativity, Technical Innovation Center, INC, Worcester, 1999

11 Savransky S D, Engieering of Creativity, New York: CRC Press, 2000

12 TRIZ Journal, https://the-trizjournal.com

13 Chen W, Renee M, Creating new market space, Harvard business Review, 1999, 77(1):83-94

14 Computer aided innovation system: InventionTool 2.0, Chinese patent of software, 2003SR9983,2003

15 Tan Runhua, Theory of Inventive Problem Solving, Science Press (in Chinese), Beijing, 2004

16 Bariani P F, Berti G A, Luccetta G, A combined DFMA and TRIZ approach the simplication of product structure, IMechE, J. Engineering Manufacturing, 2004, 218: 1203-1207

17 Mao Y J, Tesng C H, An innovative piston retractor for bicycle hydraulic disc braking systems, IMechE, J. Automobile Engineering, 2004, 218: 295-303

18 Edgardo C, Germain L, Jean M, Use of Altshuller’s Matrix for Solving Slag Problems Related to Steering Knuckle, TRIZ Journal, https://the-trizjournal.com, 2002.3

19 Dodgson M, The intensification of innovation, International Journal of Innovation Management, 2002, 6(1):53-83