Enhancing Robust Design with the Aid of TRIZ and Axiomatic Design (Part I)

Editor | On 25, Oct 2000

By: Matthew Hu, Kai Yang, Shin Taguchi

Matthew Hu

Ford Motor Company

POEE, MD 48

21500Oakwood Boulevard

P.O. Box 2053

Dearborn, MI 48121

mhu7@ford.com

Kai Yang

Wayne State University

IME Department

Wayne State University

4815 Fourth Street, Room 2151

Detroit, MI 48202

kyang@mie.eng.wayne.edu

Shin Taguchi

American Supplier Institute

38701 Seven Mile Rd

Suite 355

Livonia, MI 48152

shin@amsup.com

ABSTRACT

One of the most important tasks in robust design is to select an appropriate system output response in the study. The quality of this selection will greatly affect the effectiveness of the robust design project. Currently, this selection process is more like art than science. By using TRIZ and Axiomatic Design principle, several new approaches to enhance robust design are developed. These approaches enable us to select the appropriate system output response in a systematic fashion. The approach described in this paper was successfully applied and verified in a case study in a large automotive company.

1. INTRODUCTION

The importance and benefits of performing robust parameter design advocated by G. Taguchi are well known [1] [2] . Many people are familiar with Taguchi’s robust parameter design with such terminologies as ‘orthogonal array’, ‘signal to noise ratio’, ‘control and noise factors’. However, one of the mostly ignored but the most important task for a successful robust parameter design project is to select an appropriate system output characteristic. The identification of a proper output characteristic is a key step to have higher success rate for robust design projects. In order to identify a proper output characteristic, Taguchi suggests the following guidelines (Phadke and Taguchi [2] and Phadke [3] ):

o Identify the ideal function or ideal input/output relationship for the product or process. The quality characteristic should be directly related to the energy transfer associated with the basic mechanism of the product or process.

o Select quality characteristics that are continuous variables, as far as possible.

o Select additive quality characteristics.

o Quality characteristics should be complete. They should cover all dimensions of the ideal function or input/output relationship.

o Quality characteristics should be easy to measure.

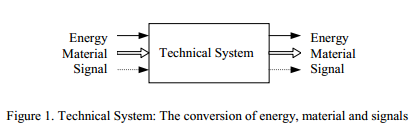

According to Taguchi, it is important to avoid using ‘quality symptoms’ such as reliability data, warranty information, scrap and % defective in the late of product development cycle and manufacturing environment, as the output characteristic. Since improving a ‘symptom’ may not be helpful in improving the robustness of system’s ability to deliver its functions, which is really the key objective of a robust design project. Understanding system function, especially basic function, is the key for robust technology development [1] . Defining the ideal state of the basic function, called ideal function, is the centerpiece for identifying output characteristic. The reason for using an energy-related system output response, according to the discussion of Pahl & Beitz [8] and Hubka [9] , is due to the fact that an engineering system is always designed for delivering its basic function. To deliver its basic function, at least one of the three types of transformation, material, energy and signal transformation (Figure 1) must be used.

Where the details of energy, material and signal include:

• Energy: mechanical, thermal, electrical, chemical… also force, current, heat…

• Material: liquid, gas… also raw material, end product, component…

• Signal: information, data, display, magnitude…

For example, a machining process as an engineering system, the ideal relationship between output and input should be that the output dimensions are exactly same as the intended dimension. This kind of the transformation system is the material transformation. Since energy transformation is a very important type of transformation, and there are many similarities in using these three types of transformation to identify the appropriate output characteristic. Without loss of generality, energy transformations are used as examples throughout in this paper. Some of the published literature and articles pointed out that energy related characteristic is very helpful to identify proper quality characteristic and should be considered. Nair [4] cites Phadke’s discussion, finding system output response that meets all of these guidelines is sometimes difficult or simply not possible with the technical know-how of the engineers involved. In general, it will be quite challenging to identify system output responses which will meet all of these criteria. Taguchi acknowledges this for fact and states that the use of Taguchi methods will be inefficient to the certain extent if these guidelines are not satisfied. Revelle, Moran and Cox [5] cites Shin Taguchi, Verdun and Wu’s work and point out that the selection of system output response that properly reflects the engineering function of a product or process is the most important and, perhaps, the most difficult task of the quality engineer. The choice of an energyrelated system output response is vital to ensure that the system output response is monotonic.

According to Box and Draper [6] , the monotonicity property requires that effects of control factor be both linear and additive. Wasserman [7] , based on the Box and Draper’s study, concludes that from response surface methodology perspective, the requirements of monotonicity property is equivalent to an assumption that the true functional response is purely additive and linear in the region of interest. The reconciliation of Taguchi’s viewpoint is possible based on the assumption that energy-related characteristics are used to ensure that interactions are minimal.

Therefore, identification of the key transformation process is very important to understand and identify the ideal functions of the engineering system. By the choice of a good functional output, there is a good chance of avoiding interactions [2,3] . Without interactions, there is additivity or consistency or reproducibility. Laboratory experiments will be reproduced and research efficiency improved.

However, the above guidelines for selecting appropriate output characteristic are still very conceptual and their implementation is highly dependent on the project leader’s personal experience. There is very little literature shown how a system output response can be designed and selected in a systematic fashion. This paper will address these shortcomings. With an emphasis on the robustness at the early stages of the product development, the proposed methodology will integrate the concept of Taguchi method with the aid of TRIZ and Axiomatic Design principles. The proposed methodology has the following three mechanisms:

• Definition and identification of different system architectures, inputs/outputs, and ideal function for each of the system/subsystem elements.

• Systematically attempts to facilitate a design that is insensitive to various variations caused by inherent functional interactions or user conditions.

• Bridge gap between robust conceptual design and robust parameter design through proper identification and selection of a system / subsystem output response.

In our paper, section 2 will review Taguchi method, TRIZ and Axiomatic design method. Section 3 will describe our method for selecting output characteristic. Section 4 will discuss the limitation of the method. Section 5 outlines some possible future research, Section 6 is the conclusion section.

2. REVIEW OF TAGUCHI METHOD, TRIZ AND AXIOMATIC DESIGN

2.1 REVIEW OF TAGUCHI METHOD

Robust design using Taguchi method is an efficient and systematic methodology that applies statistical experimental design for improving product and manufacturing process design. Dr. Genichi Taguchi’s development of robust design is a great engineering achievement (Clausing 1998) [10] . By 1990, concurrent engineering was becoming widespread in American industry. It brought great improvements. However, the pioneers such as Ford and Xerox were realizing that more was needed. Especially robust design needed to be practiced widely throughout the development of new products and processes.

Taguchi essentially uses the conventional statistical tools, but he simplifies them by identifying a set of stringent guidelines with energy transformation model focused engineering system for experiment layout and analysis of results. Taguchi used and promoted statistical techniques for quality from an engineer’s perspective rather than that of a statistician.

As Taguchi’s ideas become more widespread, more and more design engineers use Taguchi’s methodology in their everyday lives. Due to the growing popularity of robust design methods, more and more quality and engineering professionals have shifted their quality paradigm from defect inspecting and problem solving to designing quality and reliability into products or processes.

Taguchi’s approach to design emphasizes continuous improvement and encompasses different aspects of the design process grouped into three main stages:

1. System design. This broadly corresponds to conceptual design in the generalized model of the design process. System design is the conceptual design stage in which scientific and engineering expertise is applied to develop new and original technologies. Robust design using Taguchi method does not focus on the system design stage.

2. Parameter design. Parameter design is the stage at which a selected concept is optimized. Many variables can affect a system function. The variables need to be characterized from an engineering viewpoint. The goals of parameter design are to (1) find that combination of control factors settings that allow the system to achieve its ideal function and (2) remain insensitive to those variables that we cannot control. Parameter design provides opportunities to reduce the product and manufacturing costs.

3. Tolerance design. Although generally considered to be part of the detail design stage, Taguchi views this as a distinct stage to be used when sufficiently small variability cannot be achieved within a parameter design. Initially, tolerances are usually taken to be fairly wide because tight tolerances often incur high supplier or manufacturing costs. Tolerance design can be used to identify those tolerance that, when tightened, produce the most substantial improvement in performance.

Taguchi offers more than techniques of experimental design and analysis. He has a complete and integrated system to develop specifications, engineer the design to specifications, and manufacture the product to specifications. The essence of Taguchi’s approach to “quality by design†is this simple principle-instead of trying to eliminate or reduce the causes for product performance variability, adjust the design of the product so that it can be insensitive to the effects of uncontrolled (noise) variation. The losses incurred to society by the poor product design are quantified using what Taguchi calls â€loss functionâ€, which are assumed to be quadratic in nature.

The five principles of Taguchi’s methods are:

1. Select Proper System Output Response

2. Measurement of Function using S/N ratio

3. Take Advantage of Interactions between Control and Noise Factors

4. Use Orthogonal Arrays

5. Two-step Optimization

2.2 REVIEW OF TRIZ

TRIZ is a Russian acronym that stands for the Theory of Inventive Problem Solving originated by Genrikn Altshuller. How can the time required to invent be reduced? How can a process be structured to enhance breakthrough thinking? It was Altshuller’s quest to facilitate the resolution of difficult inventive problems and pass the process for this facilitation on to other people. In trying to answer these questions, Altshuller realized how difficult it is for scientists to think outside their fields of reference, because that involves thinking with a different technology or “language”. In the course of the study of some 400,000 inventions as depicted in patent descriptions, Altshuller noticed a fundamentally consistent approach used by the best inventors to solve problems. At the heart of the best solutions, as described by the patents, existed an engineering conflict, or a “contradiction.” The best inventions consistently solved conflicts without compromise. Upon closer examination and classification of innovative solutions, natural patterns of solutions started to emerge. Altshuller had discovered that when an engineering system was reduced to reveal the essential system contradictions, inventive solutions eliminated the contradictions completely. Furthermore, Altshuller noticed that the same inventive solutions appeared repeatedly at different points in time and in different places.

2.2.1 SUBSTANCE FIELD ANALYSIS

1. Substance-field analysis is a TRIZ analytical tool for modeling problems related to existing technological system. Substance-field is a model of minimal, functioning and controllable technical system [11] . Every system is created to perform some functions. The desired function is the output from an object or substance (S1), caused by another object (S2) with the help of some means (types of energy, F). The general term, substance has been used in the classical TRIZ literature to refer to some object. Substances are objects of any level of complexity. They can be single items or complex systems. The action or means of accomplishing the action is called a field. Within the database of patents, there are 76 standard substance-field solutions permit the quick modeling of simple structures for substance-field analysis. If there is a problem with an existing system and any of the three elements are missing, substance-field analysis indicates where the model requires completion and offers directions for innovative thinking. In short, substance-Field Analysis- S-F analysis is a technique used to model an engineering problem. S-F analysis looks at the interaction between substances and fields (energy) to describe the situation in a common language. In cases where the engineering system is not performing adequately, the S-F model leads the problem solver to standard solutions to help converge on an improvement. There are four steps to follow in making the Substance-field model [12] and:

i. Identify the elements.

ii. Construct the model.

iii. Consider solutions from the 76 standard solutions

iv. Develop a concept to support the solution.

2.2.2 OTHER TRIZ Tools, Strategies, and Methods

TRIZ innovative process consists of two parts: the analytical stage and the synthesis stage. A basic description of some of the instruments/tools is as follows:

1 Ideality Concept-Every system performs functions which generate useful and harmful effects. Useful effects are the desirable functions of the system, while harmful effects are the undesirable effects of the system. When solving problems, one of the goals is to maximize the useful functions of a system. The ideality concept has two main purposes. First it is a law that all engineering systems evolve to increasing degrees of ideality. Second, it tries to get the problem solver to conceptualize perfection and helps break out of psychological inertia or paradigms.

2 ARIZ- Algorithm of inventive problem solving is a non computational algorithm that helps the problem solver take a situation that doesn’t have obvious contradictions and answer a series of questions to reveal the contradictions to make it suitable for TRIZ. There are four main steps in ARIZ.

3 Contradiction Table- This is one of Altshuller’s earliest TRIZ tools to aid inventors, which shows how to deal with 1263 common engineering contradictions (improving one parameter, another is degraded).

4 Inventive Principles- These are the principles in the contradiction table. There are 40 main principles and approximately 50 subprinciples. These are proposed solution pathways or methods of dealing with or eliminating engineering contradictions between parameters.

5 Separation Principles- A technique that has been used with great success to deal with physical contradictions. The most common separation principles can take place in space, time, or scale.

6 Laws of Evolution of Engineering Systems- Altshuller found through his study of patents that engineering systems evolve according to patterns. When we understand these patterns or laws and compare them to out engineering system, we can predict and accelerate the advancement of our products.

7 Functional Analysis and Trimming- This technique is helpful is defining the problem and improving ideality or value of the system. The function of a system are identified and analyzed with the intent of increasing the value of the product by eliminating parts while keeping the functions. Functionality is maximized and cost is minimized.

2.3 REVIEW OF AXIOMATIC DESIGN

Design is attained by the interactions between the goal of the designer and the method used to achieve the goal. The goal of the design is always proposed in the functional domain, and the method of achieving the goal is proposed in the physical domain. Design process is the mapping or assigning relationship between the domains for all the levels of design. Axiomatic Design is a principle-based design method focused on the concept of domains. The primary goal of axiomatic design is to establish a systematic foundation for design activity by two fundamental axioms and a set of implementation methods [13] . The two axioms are:

Axiom 1: The Independence Axiom: Maintain the independence of functional requirements.

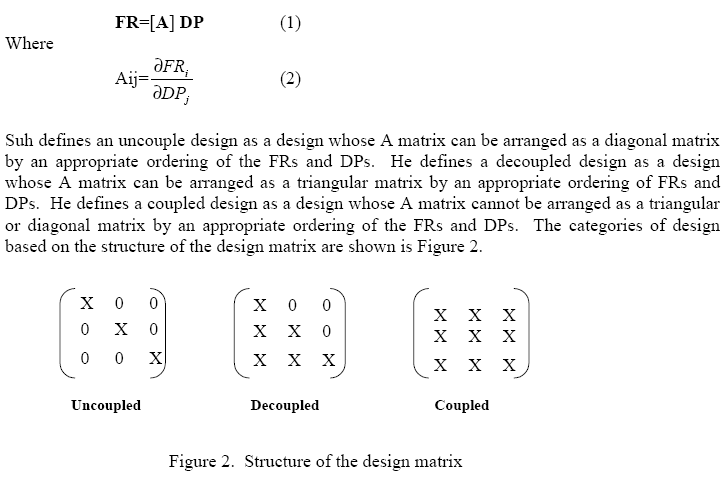

Axiom 2: The Information Axiom: Minimize the information content in design. In the axiomatic approach, design is modeled as a mapping process between a set of functional requirements (FRs) in the functional domain and a set of design parameters (DPs) in the physical domain. This mapping process is represented by the design equation:

The first axiom advocates that for a good design, the DPs should be chosen so that only one DP satisfies each FR. Thus the number of FRs and DPs is equal. The best design has a strict one-toone relationship between FRs and DPs. This is known as uncoupled design. If DP influences the FR, this element is non-zero. Otherwise it is zero. The independence axiom is satisfied for uncoupled design matrix [A] having all non-zero elements on its diagonal, indicating that the

FRs are completely independent. However, complete uncoupling may not be easy to accomplish in a complex world, where interactions of factors are common. Designs where FRs are satisfied by more than one DP are acceptable, as long as the design matrix [A] is a triangular, that is, the non-zero elements occur in a triangular pattern either above or below the diagonal. This is called decoupled design. A decoupled design also satisfies the independence axiom, provided that the DPs are specified in sequence such that each FR is ultimately controlled by on unique DP. Any other formation of the design matrix that cannot be transformed into triangular one represents a coupled design, indicating the dependence of the FRs. Therefore, the design is unacceptable, according to Axiomatic Design.

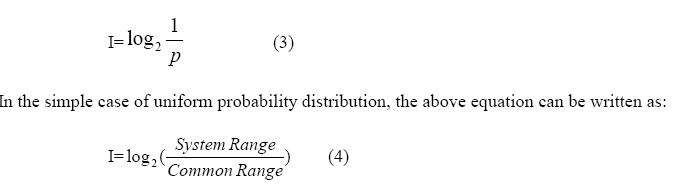

The Information Axiom provides a means of evaluating the quality of designs, thus facilitating a selection among available design alternatives. This is accomplished by comparing the information content of the several designs in terms of their respective probabilities of successfully satisfying the FRs. Information content is defined in terms of entropy, which is expressed as the logarithm of the inverse of the probability of success p:

Where, System range is the capability of the current system, given in terms of tolerances, common range refers to the amount of overlap between the design range and the system capability, and design range is the acceptable range associated with the DP specified by the designer. If a set of events is statistically independent, then the probability of the union of the events is the product of the probabilities of the individual events.

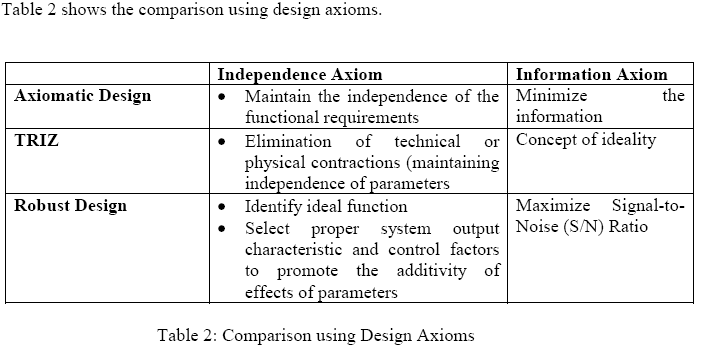

2.4 COMPARISON OF DIFFERENT DISCIPLINES

The purpose of the comparison is to point out the strength and focuses of different contemporary disciplines such as Axiomatic Design (Suh), Robust Design (Taguchi), TRIZ (Altshuller) so that the efforts of this paper will be appreciated. A product can be divided into functionally oriented operating systems. Function is a key word and basic need for describing our product, behavior. Regardless of what method to be used to facilitate a design, they all have to start with the understanding of functions. However, what is the definition of function? How the function is defined in these disciplines? Understanding the specific meanings of function (or the definition of function) within each of these disciplines could help us to take the advantages of tools to improve design efficiency and effectiveness.

According to Webster dictionary, function has three basic explanations as follows:

• the acts or operations expected of a person or thing, or

• the action for which a person or thing is specially fitted or used, or • to operate in the proper or expected manner

Generally, people would agree with that a function describes what a thing does and can be expressed as the combination of noun and verb. For example, creating a seal, send an e-mail and etc.

In Axiomatic Design, function is defined as desired output that is same as the original definition. However, the importance of functional requirements is not identified in axiomatic design framework. There is no guidelines or termination criteria for functional requirement decomposition. Functional requirements are treated equally important which are not necessary practical and feasible.

In Robust Design, the definition of function has the same general meaning but with more further meaning in terms of ideal function, which is concerned about what fundamental things a system is supposed to know-how the energy can be transferred smoothly. For example, how a seal can be formed effectively? What is the basic function of engineered seal system. Therefore, the definition of function in robust design using Taguchi method may best be defined as energy transformation.

In TRIZ methodology, the definition of function also has the same general meaning with negative thinking in terms of physical contradictions. Altshuller seeks to deliver all system functions simultaneously with maximization of existing resources.

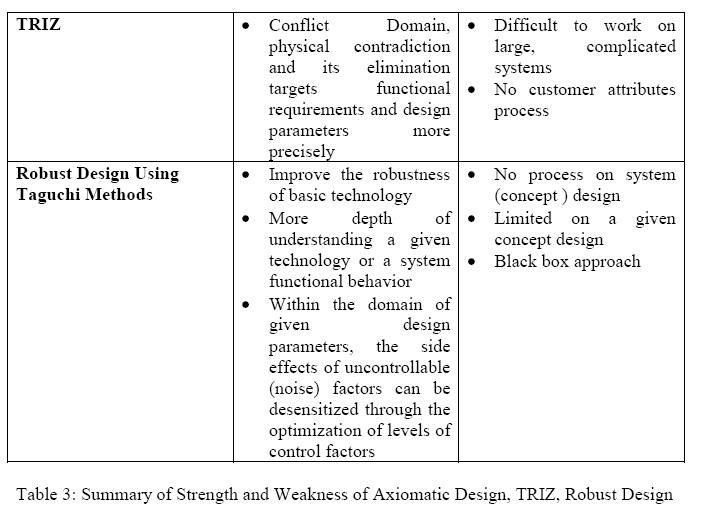

Table1 shows the comparison of Axiomatic Design, TRIZ and Robust Design.

3. DESIGN RESPONSE STRUCTURAL ANALYSIS: A STRUCTURAL

APPROACH FOR IDENTIFICATION OF SYSTEM OUTPUT RESPONSE

Any system output response is in one of the forms of energy, material and signal. If the energyrelated system output response can help to reduce the interactive effects of design parameter to minimal for the purpose design optimization, we better to find a way of converting non-energy related system output response to an energy-related system output response. Instead of blindly searching an energy related system output response based on empirical approach, experience, it is necessary to develop an energy-related system output response. With respect to technical system, any technical system consists of three minimal numbers of elements: two substances (objects) and a field (energy) [11] . A substance can be modified as a result of direct action performed by another substance. Having the same thought process, a system output response can also be modified as a result of direct action performed by another substance, which can be used as input signal from Taguchi method’s perspective. The substance field analysis concept furnishes a clue to the direction of developing a system output response.

Example 1: in a product improvement task, the plastic molding strength has to be improved to certain withstand force.

The objective function in this case is to improve the strength. What is the output response in this case study? Many people would agree that the characteristic (output response) of push force (Force to break the molding) could be the one (Figure 3).

The concern of using push force as the output characteristic may be summarized as follows:

• It is difficult to understand the structure of the material such as bubbles or voids

• It is a destructive test

• It is hard to take the advantage of signal factor in a robust design experiment. In other words, it is hard to understand the input and output relationship in this engineered system.

In an evaluation of functional behavior of a system, failure modes are only symptoms. The evaluation of that will not provide insight on how to improve the system. Therefore, the push force characteristic is not a good system output response in this case study. What choice can we have a proper characteristic instead of using push force to evaluate the strength? Let us analyze the problem and its solution in detail:

First, as the conditions of the problem suggest, there is nothing else can be selected to evaluate the strength: the direct response of the engineered system is out of consideration. Therefore, a new system output response should be created.

In the figure 4, there was one substance (a piece of plastic molding) at the beginning, in the end there was two substances (a piece of plastic molding and a push bar) and force field and the piece of plastic molding bent (not broken). We use the following symbols to represent the operation:

Let us now look at how the system works. Mechanical field (F push force) acts on push bar S2 which, in turn, acts on the piece of plastic molding (S1). As a result, S1 is deformed (bent) to S1′. Graphically the operation can be represented as follows:

Up to now, can we be able to see the alternative system output characteristic? Can the S1′ be used to evaluate the system behavior instead of push force? Let’s validate this idea: can the evaluation system work if we take off any of the substance? No, the system will fall apart and cease to apply the force to the piece of plastic molding. Does this mean that evaluation system’s operation is secured by the presence of all of its three elements? Yes. This follows from the main principle of materialism: substance can only be modified by material factors, i.e. by matter or energy (field). With respect to technical systems, substance can only be modified as a result of direct action performed by another substance (for example, impact- mechanical filed) or by another substance. S1′ is modified from S1 and is the output due to system input force of Fpush.

The characteristic S1′ is more close to the structure of plastic molding than the push force.

According to [Hubka84] , in order to obtain a certain result (i.e. an intended function); various phenomena are linked together into an action chain, in such a way that an input quantity is converted into an output quantity. This chain describes the mode of action of a technical system. The mode of action describes the way in which the inputs to a technical system are converted into its output effects. The mode of action is characterized by the technical system internal conversion of inputs of material, energy and information. The output effect is achieved as the output of an action process (through an action chain) internal to the technical system, in which the input measures are converted into the effects (output measures) of that technical system. The action process is a direct consequence of the structure of the technical system. Every technical system has a purpose, which is intended to exert some desired effects on the objects being changed in a transformation process. The behavior of any technical system is closely related to its structure.

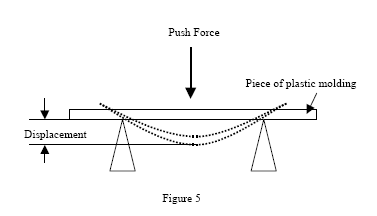

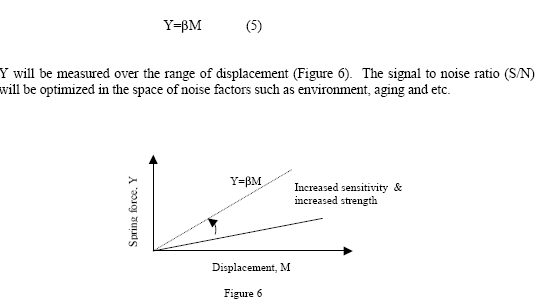

As a consequence, the S1′ (the bent S1) in terms of displacement (bent distance) is a better system output response (figure 5). As a matter of fact, the displacement of S1′ is proportional to the push force, which enhances effectiveness of the efforts of robust parameter design. A robust parameter design case study has been developed successfully using the output characteristic of displacement in an automotive company [14] , [15] .

In robust design approach using Taguchi method, the displacement M can also be used as an input signal. The spring force Y, within the elastic limit, can be used as system output response. The displacement is an input signal M. Then the ideal function will be given by

Identification of system output response using S-field models shed light on the essence of transformation of engineered systems and allows using universal technical or engineering terminology rather than customer’s perception such as percent of failures, good or bad to evaluate the system’s behavior. The key idea is that how the material, information and energy is formed or transferred.

Searching for system output response based on S-field model analysis presents a general formula that shows the direction of identifying the possible system output characteristic. This direction depends heavily on the design intent of the system. Consider the example above: introducing a substance or a field will profoundly change the process of identifying the system output response.

Gathering expert knowledge about the engineered system and various components in the product, and how they affect one another, is of the most importance if the identification of system output response can be more effective.

There are several rules of identifying system output response using S-field synthesis. Since we are interested in identifying proper system output characteristic in this paper. Our goal is to develop some principles for identification of system output response using S-field analysis.

RULE 1 (SUBSTANCE-FIELD MODEL DEVELOPMENT FOR SYSTEM OUTPUT RESPONSE)

If there is an output characteristic which is not easy to measure or not proper to reflect the system design intent, and the conditions do not contain any limitations on the introduction of substances and fields, the output characteristic can be identified through synthesizing a system output response based S-field: the output characteristic is subjected to the action of a physical field which produces the necessary corresponding physical effects in the engineered system.

RULE 2 (CHANGE THE SCOPE OR BOUNDARY OF A TECHNICAL SYSTEM)

If the conditions contain limitations on the existing system output response, the alternative output response has to be identified by synthesizing a S-field using external environment as the system output response. Changing the scope or the boundary of the technical system can help to identify a proper system response.

Example 2:

To illustrate this, let’s use the case study of A Research On The Temperature Rising Problem For

A Printer Light Generating System [16] as an example.

Background

During the development stage of a printer, it was noticed that the temperature in the light source area was much higher than expected. To solve this problem, there are some possible countermeasures such as upgrading the resin material to retard flammability or adding a certain heat resisting device. Since these countermeasures would result in a cost increase, it was decided to lower temperature. However, trying to lower temperature creates the need to measure temperature. Such an approach is not recommended because of two reasons.

First, the environmental temperature must be controlled during experimentation. Secondly, the selection of material must consider all three aspects of heat transfer, i.e., conduction, radiation and convection. It would take a long time to do.

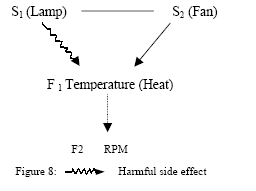

In the system of this example, there are two sub-systems: S1-lamp (light generating system) and S2-fan (cooling system). The heat (field) in this system must be reduced. Since the heat energy is created by S1 (lamp) and to be cooled by S2 (fan). The S-field system diagram may be drawn as in Figure 7.

The constraints for the problem solving in this example are:

1. S1 cannot be changed.

2. Temperature is not preferred to measure the heat accumulated around the system.

3. RPM meter gage is not available.

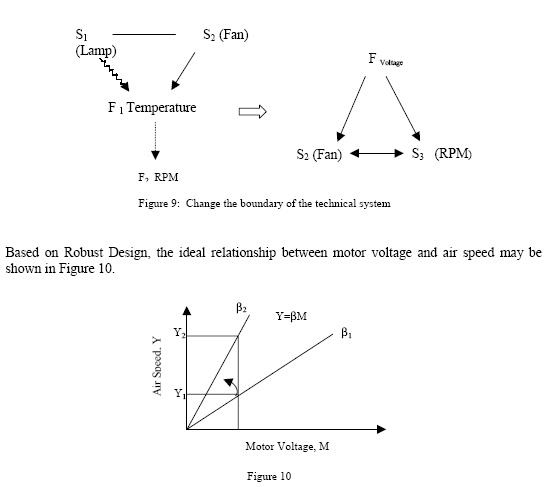

What else can be measured to evaluate the status of temperature? Obviously, the rotation of the fan to remove the air surrounding the heat source could be another way of improving temperature condition. In order to improve the rotation of fan, rpm has to be measured. The ideal situation is “the air speed surrounding the heat source changes proportionally to the fan rotation. The sensitivity must also high”. The modified S-field is shown is Figure 8.

However, as stated in the constraints, measuring rpm is not possible at that time unfortunately. What can we do now? According to rule 2, we may have to change the scope or the boundary of the technical system. Can we find something that is not related to temperature directly? Of course, our goal is still to find a way of measuring heat for the purpose of achieving lower temperature as possible. Can we use motor voltage to measure the temperature indirectly? Let’s validate this idea. Voltage is the input energy to drive a motor. The rpm of a fan, as the result of motor rotation, is likely proportional to motor voltage. Therefore, the ideal situation can be redefined as “the air speed surrounding the heat source is proportional to motor voltage with high sensitivity.” The further modified S-field is shown in Figure 9.

Technical system displays numerous internal and external connections, both with subsystems (components of each technical system), systems of a higher rank and the environment. Each technical system can be represented as a sum of S-field. The tendency is to increase the number of S-Fields in a technical system with the consideration of chain of action mode as necessary.

RULE 3.

Efficiency of system output response based S-Field analysis can be improved by transforming one of the parts of the system output response based S-Field into an independently controllable system output response based S-Field, thus forming a chain of system output based S-Field analysis.

The graphical view of the chain of the system output response based S-Field is in figure 11.

RULE 4 (CHAIN OF ACTION AND EFFECT FOR SYSTEM OUTPUT RESPONSE)

If an output characteristic is conflicting with another output characteristic in terms of same design parameters. It is necessary to improve the efficiency by introducing a substance or a sub S-field and consider the chain of action in a technical system.

Rule 3 and rule 4 are often used together to identify a proper system output characteristic. For example: in a mechanical crimped product case study [17] , both pull strength force and voltage drop have to be optimized simultaneously (figure12). But the optimized design parameters are not the same with respect to the two different system output responses. Obviously, something may have to be compromised unfortunately.

The reliability of complex electrical distribution systems can be dramatically affected through problems in the connecting elements of wire to terminal in this case study. Minimum voltage drop is the design intent and the maximum pull strength is required for the long-term reliability concerns.

In this example, the pull strength is created by crimping force (F1) acting on wire (S1) and terminal (S2). The S-field system diagram may be expressed as (Figure 13):

The pull strength F2 is not a good system output response for two reasons: first, pull strength has to be compromised by voltage drop. Second, the pull strength does not take the long-term reliability into the consideration in terms of gas holes, void and etc. According to rule 4, we could introduce an output response and consider the chain of action modes and the chain of effects. What effect can we find before the effect of pull strength formed? When we crimp the wires and terminal, the wires and terminal are compressed into certain form. Such form can be measured by compactness. Can the compactness be used as a system output response? Let’s validate this idea.

The compactness is formed before the pull strength. And the compactness takes the gas holes and voids into the consideration. What is the relationship between the compactness and pull strength? The data show that the compactness is strongly related to the pull strength and the voltage drop. Therefore, the compactness could be used as a system output characteristic. The S-field diagram can be modified as follows (Figure 14):

The identification system output response using Substance-field analysis is based on the law of energy transformation and the law of energy conductivity. Selecting a proper system output response using S-field analysis is one of the approaches based on the energy transformation thought process. Any technical system consists of three elements: two substances and a field. The identification system output response using Substance-field analysis furnishes a clue to the direction of identifying a system output response for the purpose of conducting robust parameter design through dynamic approach. This approach is very helpful when it is not clear how an object or a system, especially in the process of identifying a system output response, related to the energy transformation for the purpose of design optimization.

4. LIMITATIONS OF THE PROPOSED APPROACH

Searching for a proper system output characteristic through the system output response based SField model, we often look at the technical system at only one level. In a more complex system, it is hard to identify a proper system output response without looking into the structure of the system design. A thorough understanding of the design intent is the essential for finding a way to identify a truly engineering related output response.

5. FURTHER RESEARCH

One interesting topic might be to investigate how the framework of Axiomatic Design could be

used to improve the limitations of identifying system output response using substance-field

analysis. Of course, we would like to investigate a way of bridging the gap between the

conceptual design and parameter design so that the upfront robustness thinking and the testability

can be emphasized. Design through axiomatic approach is attained by interactions between the

goal of the designer and the method used to achieve the goal. The goal of the design is always

proposed in the functional domain, and the method of achieving the goal is proposed in the

physical domain. Design process is the mapping or assigning relationship between the domains

for all the levels of design.

As the functional requirements become diverse, satisfying the requirements become more

difficult. Therefore, concentrating on the functional requirements for the given stage or level of

the design process is necessary. A design or a problem with many variables is very complicated.

In order to prioritize the tasks and the proper focus, it is necessary to sort the primary and

secondary functional requirements and handle each functional requirement according to the

precedence of importance. For the purpose of design evaluation and optimization, it is essential

to select a proper system output response to evaluate and understand an engineered system or a

product ‘s functional behavior. Such system output characteristic (response) should be basic

function related. Basic function is a function to transfer material, energy and information from

the input of the system to the output of the system. Obviously, the basic function of a product or

process technology is related to its capability (highest probability) to transform input to output in

terms of material, information and energy.

Functional requirement is included in the functional domain. The designer should thoroughly

understand problem in the functional domain and should not limit any possible selections

without a special reason. Clearly defining the problem is closely related to defining the

functional requirements. On the other hand the designer should select the design elements in the

physical domain by specifying the functional requirements physically. Selecting a system output

response characteristic is closely related to the physical domain to reflect how material,

information and energy are transferred smoothly from input to output in the technical system.

According the axiomatic design principles, the essence of design process lies in the hierarchies.

The designer begins with functional requirements (top-down approach). And because of the

different priorities of all the functional requirements, the designer can categorize all the

functional requirements into different hierarchies. The important point in this process is that the

functional requirements must be satisfied with specific design parameters. As it goes to the

lower level more details should be considered. This can be a very effective way of considering

all details of the design. The functional requirements of the higher level must be satisfied

through the appropriate design parameters in order for the lower level functional requirements to

be satisfied.

By using axiomatic approach the ideas in the initial stages of the design can be materialized in a

scientific way. Once the design zigzagging mappings have been completed according to the design axiom. One of the most of important tasks is to understand how the system behavior can be evaluated. In order to evaluate the system’s functional behavior, of course, a key system output response has to be identified. The lower level of functional requirement in the axiomatic design framework is not necessary the good system output response for the purpose of system evaluation. But the lower level of functional requirement is certainly the proper starting point to identify or develop a proper system output characteristic. Additional creativity in the design can be induced when going through this task.

The bottom-up approach is necessary to identify a system output response based on a result of zigzagging mapping. The details of identifying system output response through axiomatic design axioms are presented in Part II.

6. CONCLUSIONS

This paper suggests an approach for identifying a proper system output response using

substance-field analysis along with the analysis of chain of action mode. The approach

presented consists of four rules:

(1) System output response focused substance-field model development

(2) Change the scope or boundary of a technical system

(3) Efficiency of system output response focused substance-field model

(4) Chain of action and effect for system output response

The law of energy transformation and the law of energy conductivity guide the identification of

system output response using substance-field analysis. One of the biggest advantages using this

approach is that the signal factor will come with the identified system output response. With the

proper identification of signal factor and the system output response, the chance of using

dynamic robust design will be increased. Of course, the effectiveness of the robust parameter

design will be improved.

Compared with other approaches to the identification of system output response, the approach presented in this paper provides a specific and detail directions to not only search for but create an energy related system output response.

The presented approach was successfully applied to several challenging case studies at some automotive companies. The findings from the case studies motivated the research to bridge the gap between the robust conceptual design and the robust parameter design.

REFERENCES

[1] Taguchi, G., Taguchi ON ROBUST TECHNOLOGY DEVELOPMENT Bring Quality Engineering Upstream, 1993, The American Society of Mechanical Engineers, Yew York, NY.

[2] Taguchi, G., System of Experimental Design, Unipub/Kraus International Publications, White Plain, NY, 1987.

[3] Phadke, M.S., Quality Engineering Using Robust Design, Prentice-Hall, Englewood Cliffs, NJ, 1989.

[4] Nair, Vijayan N., “Taguchi’s Parameter Design: A Panel Discussion,” ECHNOMETERICS, May 1992, Vol. 34, No. 2.

[5] ReVelle, J. B., Moran J.W., and Cox, C.A., The QFD Handbook, John Wiley & Sons, INC. 1998.

[6] Box, G.E, and Draper, N. R., Empirical Model-Building and Response Surface Methodology, John Wiley and Sons, NY, 1988.

[7] Wasserman, G.S., “The Use of Energy-Related Characteristics in Robust Product Design.”, Quality Engineering, 10(2), 213-222 (1997-1998).

[8] Pahl, G., and Beitz, W., 1988, Engineering Design: A Systematic Approach, Springer Verlag.

[9] Hubka, V., and Eder, W. E., 1984, Theory of Technical System: A Total Concept Theory for Engineering Design, Springer-Verlag.

[10] Clausing, D., “Product Development, Robust Design, and Education.”, 1998, 4th Annual Total Product Development Symposium, American Supplier Institute.

[11] Salamatov, Y. “TRIZ: The Right Solution at the Right Time.” Published by Insytec B.V. 1999.

[12] Terninko, J., Zusman, A., and Zlotin, B., “Step-by-Step: Creating Innovative Solution Concepts.” 1996, Responsible Management Inc.

[13] Suh, N.P., 1990, The Principles of Design, New York, NY: Oxford University Press.

[14] “Improvement of An Aero-Craft Material Casting Process.”, Quality Engineering Forum, 1995. Japan.

[15] Hu, M., “Reduction of Product Development Cycle Time.” 3rd Annual International Total Product Development Symposium, 1997, American Supplier Institute.

[16] “A Research on the Temperature Rising Problem for a Printer Light Generating System.” Quality Engineering Forum, 1996, Japan.

[17] Hu, M., Meder, A., Boston, M., “Mechanical Crimping Process Improvement Using Robust Design Techniques.” Robust Engineering: 17th Annual Taguchi Methods Symposium Processdings, 1999, Cambridge, Massachusetts. American Supplier Institute.

[18] Altshuller, G., translated by Shulyak, L., And Suddenly the Inventor Appeared-TRIZ, the Theory of Inventive Problem Solving, Technical Innovation Center, INC. Worcester, MA, 1996.