Dynamization evolution of Dry Etch Tools in Semiconductor Device Fabrication

Editor | On 02, Dec 2005

By: Gordon Cameron

Abstract

Engineering Systems follow recognized trends of evolution; the main parameters of a system will evolve driven by the competitive need to increase value. This article provides an overview of the Trend and sub-trends of Increasing Dynamization. The evolution Dry Etch tools used in Semiconductor Device Fabrication is discussed in detail as a trend of Field Dynamization.

Introduction

All Engineering systems trend towards increasing ideality over time. Engineering Systems evolve to increase ideality by the Ideality Law: Ideality=Value=ΣF/ ΣC = functionality/cost. Essentially, a system is more survivable if we get more, pay less. The ideal system is when cost is zero or Functionality is infinity (an infinitely functional system is not possible).

Engineering systems evolve such that the main parameters follow S-shaped curves towards increasing ideality. This “Law of increasing Ideality†is what drives an engineering system along the S-curve. Systems push up along the S-curve because they need to become more effective to survive in a competitive market.

Trends of Engineering System Evolution

The emergence and implementation of innovation is not random but follows specific evolutionary patterns driven by this Ideality Law. Analysis of historical patterns of evolution has revealed a number of Trends and Sub trends that drive Engineering System Evolution. These Trends of Engineering System Evolution (TESE) are summarized in hierarchical order (fig 2).

The recognized Trends can be used to predict possible evolutionary paths for systems and provide possible solutions for problem resolution or system improvement.

We will discuss the trend on Increasing Dynamization with examples of the four subtrends with illustrative examples, including the specific example of the evolution of Dry Etch tools used in Semiconductor Device Fabrication as a trend of increasing Field dynamization

Trends of Increasing Dynamization

Definition: As an engineering system evolves, it and its components become more dynamic (where dynamic is the ability to change parameters in time).

There are four Sub-trends: 1.Design Dynamizaton with its’ own two sub-trends. 1.1 Substance Dynamization 1.2 Field Dynamization, 2. Composition Dynamization, 3. Internal Structure Dynamization,

4. Function Dynamization.

1. Trends of Increasing Design Dynamization

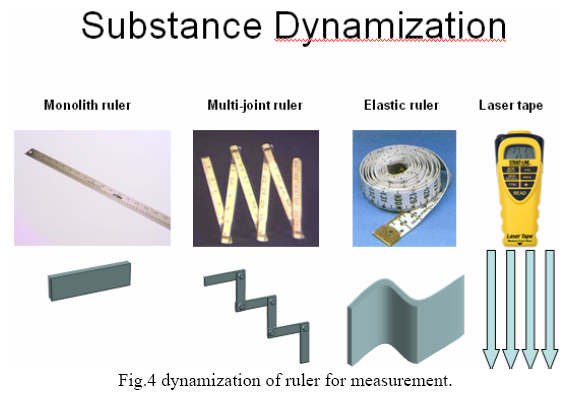

1.1 Substance Dynamization 1.2 Field Dynamization

• Monolith system Constant Field

• System with shifted parameters Gradient Field

• One joint system Variable Field

• Multi-joint system Impulse Field

• Elastic system Resonance Field

• Powder System Interference Field (including

• Liquid system standing and running waves)

• Gaseous System

• Field System

Systems evolve along the substance trend, from a monolith to a field and fields evolve from a constant to gradient, variable, impulse, resonant and interference.

1.1 Substance Dynamization

Examples of the trend of Increasing substance Dynamization.

1.2 Field Dynamization

• Constant Field

• Gradient Field

• Variable Field

• Impulse Field

• Resonance Field

• Interference Field (including standing and running waves)

Example of Field dynamization: Evolution of Etch Process Systems in Semiconductor Device Fabrication.

Dry Etch systems follow the trend of increasing Field Dynamization. Dry Etch Systems have evolved from Wet etch (no field), to Plasma Etch (constant RF field), Reactive Ion Etch (gradient), Magnetically Enhanced Reactive ion etch (variable) to Electron cyclotron resonance (resonance).

The trend of Field Dynamization predicts the next stage of evolution of dry etch systems used for High Volume Manufacturing as Interference generated. Systems where ions are excited by interference fields to achieve increased control of the etching process as critical dimensions shrink. With this prediction we can pursue development of such a tool using standard TRIZ methodology.

A. Wet Etch (no field)

• Normally 25 or 50 wafers are etched in an appropriate chemical bath for a fixed time. Etching is isotropic.

B. Plasma Etch: Planar Diode/Plasma Mode Configuration (Constant Field)

Silicon wafers are patterned with photoresist. A plasma is generated between two planar electrodes by applying an RF (Radio Frequency) voltage. The plasma ionizes an appropriate gas or gases that react with the thin film on the wafer to remove material not masked by the photoresist. The photoresist is later removed and a patterned film has been formed as part of the semiconductor device.

A Planar Diode (equal electrode surface area) etcher produces isotropic etching (no directionality/control of lateral etching).

Reactive Ion Etch (RIE) Configuration (Gradient field)

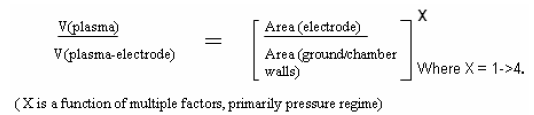

Directional/Anisotropic Etching is used to improve profile (dimension) control of the etched features sidewalls. This is achieved by generating a DC bias (gradient) resulting from asymmetry in electrode surface area (wafer on smaller electrode). The DC bias is a potential drop between the plasma and the wafer that accelerates ions towards the wafer to produce directional etching.

RIE configuration also requires blocking capacitor (to ensure zero net current flow) and asymmetry of Electrode size in an RF plasma to cause a DC bias (gradient) to be generated.

Because of the DC bias, when positive ions reach to the edge of the plasma above the electrode they accelerate towards it and impact the surface causing the vertical etch rate to be greater than the lateral etch rate -> directional etching is achieved.

How the tool is configured (Electrode configuration), type of power source (RF/Microwave), gases, pressure etc determine the energy at which ions strike the wafer and the degree of ionization, these dictate the etchers’ capability to control directionality and etch rate.

If there is no blocking capacitor, at high electron current (-ve there is a low ion current +ve). The blocking capacitor requires that no net current exists and therefore the applied voltage must bias itself negatively with reference to the plasma.

If RF power is increased, RF peak to peak voltage increases (Vpp). At higher Vpp, DC bias (Vdc) will also increase. Higher RF power -> higher DC bias, ions extracted from plasma towards the wafer electrode are more energetic.

RIE configuration has a smaller electrode (the wafer location) that is biased negatively to the plasma. Ions accelerated from plasma to the wafer provide directional etching due to the DC bias electric field (GRADIENT).

Plasma mode has no self bias generated, isotropic etching, ions are accelerated only via Plasma Potential typically 10-30V (DC) above ground which is not sufficient.

Relationship of DC bias to Electrode area to electrode area (empirically derived).

The DC bias varies inversely to the ratio of the area of cathode to ground. When the wafer electrode area decreases, DC bias increases.

C. Magnetically Enhanced RIE (MERIE) Configuration (Variable Field)

Directional/Anisotropic Etching is achieved by asymmetry in electrode surface area (wafer on smaller electrode) like RIE. A rotating magnetic field is added via external coils that switch (oscillate) between N and S or physically rotate permanent magnets.

Electrons generated by the RF field spiral around magnetic field lines, this increases the electron path which increases the probability of a collision with a gas molecule resulting in a more dense (ionization) plasma. Thus etch rate can be enhanced without additional RF power when compared to the standard RIE configuration.

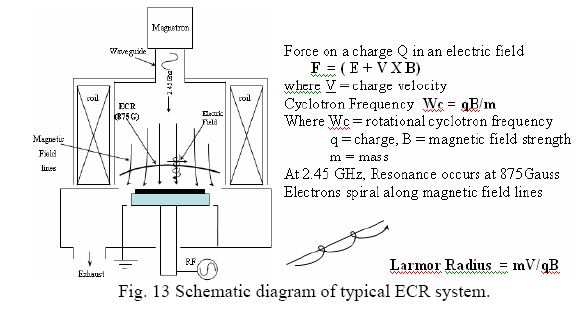

D. Electron Cyclotron Resonance (ECR) (used for high aspect ratio small geometry control: Silicon trench etching, Polysilicon gate etch)

• Magnetron generates Microwave input at 2.45 GHz.

• Electrons spiral vertically along magnetic field lines.

• Magnetic field strength 875 Gauss -> dome shaped contour.

• RF Power supply used to generate DC bias independently of plasma ionization.

Extracts ions by adjusting RF power

• Low Pressure -> mean free path is long. Electrons travel far enough to gain sufficient energy to strike gas molecules and cause ionization.

• Helium Backside cooling used to control wafer temperature.

Dense ionization occurs where a magnetic field and em wave (microwave) interact with charged particles (electron) within the gas in a partially evacuated chamber. When certain conditions are met (Wc = qB/m), the microwave frequency matches the charge/mass (electron) x the magnetic field strength, resonance occurs and the input power is efficiently transferred to the electron.

Electrons spiral along the magnetic field line (longer distance at lower pressures). Because of the increased distance traveled (spiral vs. straight in RIE) the energy gained by electrons is higher, more ionization occurs. This enables practical etch rates to be achieved at low pressures.

At a point where the magnetic flux density satisfies the resonance condition B=m/q, electrons spiral around the field lines at an angular frequency equal to the microwave electric field. These electrons are continuously accelerated by the microwave oscillation because they change direction in phase with the alternating electric field. (Resonance-> efficient energy transfer) ECR draws energy efficiently from the microwave supply into the plasma. This produces dense ion rich plasma.

ECR the electric field frequency W = Wc at resonance, this occurs at W = qB/m and maximum energy absorption of the electric field occurs. At 2.45 GHz, for an electron, resonance will occur at 875 Gauss.

E. Interference

The trend of Field dynamization predicts interference as the next source of ionization for Etch systems to be used in HVM Semiconductor Fabrication, for increased profile control as device dimensions shrink and feature aspect ratios increase. Standard TRIZ problem solving tools can be used to develop this next step in the evolution.

2. Composition Dynamization (less like a trend more like a group)

The composition of the system becomes dynamic, examples are:

• System in the form of a set of plates

• Brush Design

• System of Unfixed Pins or Balls

• Spongy System

3. Internal Structure Dynamization (Dynamization of structure at micro level).

The internal Structure of a system becomes more dynamic.

• Almost always smart materials are used e.g. shape memory alloy or bi-metal plate.

4. Function Dynamization

The System develops more functions.

• Mono-functional becomes Poly Functional

Conclusions

Increasing Dynamization is an evolutionary trend of increasing control. Dynamization tends to evolve in specific ways (trends/sub trends) over time. As an engineering system evolves, it and its components become more dynamic (dynamic meaning the ability to change parameters in time).

Structures tend to evolve from rigid to hinged to multi-jointed to flexible to field. Fields evolve from constant to variable, resonant etc. Composition can dynamize to become plate-like brush-like or spongy, internal structure becomes linear/non-linear, single/multi level and mono functional systems evolve to multi-functional.

Almost any system which is stiff or static will become dynamic, driven by the Law of increasing Ideality.

Examination of the Trends of Engineering System Evolution can be used to predict the future development of an Engineering System or component.

Dry Etch systems used in semiconductor device fabrication have been shown to follow the trend of increasing field dynamization. The trend of Field Dynamization predicts the next stage of evolution of dry etch systems used for High Volume Manufacturing to be Interference generated ionization. Systems where ions are excited by interference fields to achieve increased control of the etching process as critical dimensions shrink and aspect ratios of features increase. With this prediction we can pursue development of such a tool using standard TRIZ methodology.

Knowledge of the trends of evolution can be used as a conceptual method to generate solutions to problems; it can suggest how to improve an interaction or system by considering dynamization as an inventive principle and as a future stage of evolution.

Acknowledgements.

I am grateful to Alex Lyubomirskiy and Sergei Ikovenko of GEN3 Partners Inc. for the use of some of their material used as illustrative examples and specifically for Fig. 2 which illustrates the hierarchical structure of the General Trends of Engineering System evolution.

About the Author

Gordon Cameron is Staff Process Engineer at Intel Corp. based in Arizona, responsible for troubleshooting and problem solving. He has 20+ years experience in the Semiconductor Industry in etch process engineering and development. He has published several articles on dry etch and defect elimination, is a Physics graduate of the University of Glasgow, Scotland., and learned TRIZ from GEN3 Partners Inc. Professional Training.