Develop New Kind Of Plough By Using TRIZ And Robust Design

Editor | On 16, Jun 2003

By: Zhao Xinjun

School of Mechanical Engineering and Automation

Northeastern University, P.R.China

xinjun_zhao@yahoo.com.cn

Abstract

The main part of plough is the share, it digs into the soil, separates the surface soil from the bed soil and then moldboard turns it upside down, but the share’s life is very short which is because the friction between the share and the soil. The paper will present a case study of successfully using TRIZ methodology and Robust Design to solve a longstanding design deficiency of plough. Using Su-Field analysis method and physical effects, engineers found a way to reduce the friction with magnetic field and came up with a low-cost solution using existing plough. Robust Design was used next to optimize the settings of the solution. The resulting feature was put into production, and it greatly increased customer satisfaction, prolonged share’s life and fortunately after the new plough cultivated the crop yield could be increased.

1 PLOUGH AND TRIZ

As a research project, TRIZ was introduced to and practiced during design of the plough by learning and experimenting with TRIZ while doing the work. The project had multiple goals, one of which was using TRIZ to tackle a real life technical problem. The problem the group decided to take on was the friction problem on the share of plough.

2 THE PLOUGH SYSTEM

Fig.1 is the sketch of a mono-plough, the main parts of it is the share. When working, the share first digs into the soil, separates the surface soil from the bed soil and then the moldboard turns the upper soil upside down. During cultivation, the share’s life is very short which is because of the big friction between the share and the soil. And the cultivated quality was depended on the share greatly.

3 PAST ATTEMPTS TO SOLVE THE PROBLEM

In the past, several attempts have been made to remedy the share-friction problem. Different kinds of alloys have been tried to manufacture the share. Although some kinds of share made of alloys were working well and the share friction is much lower, but the cost was much higher and the customer could not afford it normally. Another attempt was to make the plough, especially the share, to vibrate when cultivating soil. The plough equipped with the vibrating system could reduce the share friction and prolong its life, but the addition of the vibrating system make the cost of the plough increase sharply and some negative effects were derived from the vibrating system. As a result, the farmer hope the share of plough working longer and cost lower, so it is very important to develop new kind of share on the plough.

4 PRACTICING S-FIELD ANALYSIS METHOD

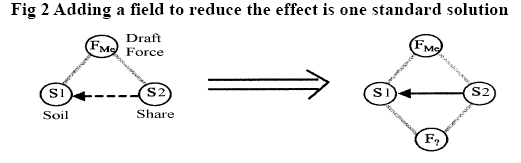

First, the S-Field of the plough was analyzed as Fig.2. S1 is the soil, S2 is the share, and Field is the mechanical force—the draft force of the tractor.

There are several possibilities for field, which will reduce the effect of friction:

· a pneumatic field using pressure air.

· a magnetic field to magnetize share to improve friction.

Selecting a different solution from the Standard Solutions. Insert a substance S3 and another field F2 (Fig.3) to develop a concept to support the solution.

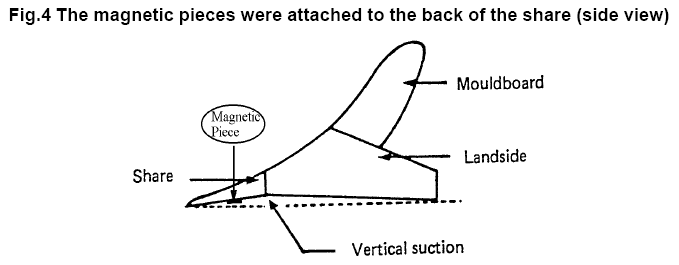

FM is magnetic field and S3 is magnetic pieces, which attached to the back of the share (Fig.4). The magnetic field (the magnetic field intensity is higher) will affect the soil, causing the share friction to go down.

5 ROBUST DESIGN FOR OPTIMIZATION

The new kind of magnetic plough was shown as Fig.4. The small magnetic pieces were attached to the back of the share, then the magnetic field was formed around the share and change the relations between the soil and the share, therefore reduce the share friction.

For field implementation, the magnetic intensity of the share and the working speed of the plough must be optimized to make plough work well and cost lower. But the share friction is very difficult to be measured, so the two parameters, the plough draft and the engine fuel consumption, were chosen to measure instead of the share friction. A simple two-factor (the speed and the magnetic intensity), three-level DOE was used, and three repetitions were run for each of the nine settings (Table 1).

The output of the experiment was a numerical representation of how the plow draft or fuel consumption was, the lower the plow draft or fuel consumption, the lower the share friction was. An average output of 70.46 (No.8) represents a better condition, where an average output of 31.36 (No.1) represents a worse condition. The optimizing settings were achieved with No. 8 (A3, B2).

The contrast experiments between the magnetic plough with No. 8 (A3, B2) and the normal one were done at the same condition like below: The experiment plough with 4 mono-plough, the soil was burozem and soybean field last summer, soil compaction was 30.28 N/cm3, soil water content was 15.98 %, plow depth was 22.5 cm and the mono-plow width was 20 cm.

The experiment results showed that the magnetic plough saved the plow draft 10.55 % and reduced 11.3 % fuel consumption than the normal plough did. The result proven fully that the magnetic plough could surely get the achievement of saving plough draft, reducing fuel consumption of the engine and finally reduce the share friction, increase the share’s life.

Another result was out of expected, compared with the normal field, the crop was grown better on the magnetic plough cultivated field and the crop yield was increased than the normal plough field did.

6 CONCLUSIONS

Using S-Field analysis method, a methodology derived from TRIZ, in combination with DOE (Design of Experiment), magnetic share of plough solved a long-standing share friction deficiency in the cultivated machines. The addition of some small magnetic pieces on the share will increase the total cost of the share, but the saving of plough draft and reducing fuel consumption of the engine can compensate the cost, the farmer also could afford it.

REFERENCES

1. Former Soviet Union, Science and Living, 1989.11

2. Altshuller, G. S. (Genrikh Saulovich). Creativity as an Exact Science: the Theory of the Solution of Inventive Problems , New York: Gordon and Breach Science Publishers, 1984.

3. Taguchi, Genichi, System of Experimental Design: Engineering Methods to Optimize Quality and Minimize Costs, White Plains, N.Y.: UNIPUB/Kraus International Publications, 1987.

4. Han guozhong, Research on the Plow Draft of Magnetizing Plow, Transaction of the Chinese Agricultural Machinery, 1991.9,25-29

5. Diao weijian, Chinese Patent, Number: N 2082072 U, 1991.8.7

6. Liu xiaoyi, Effect of Magnetism on Soil Water Holding Property, Chinese Soil Report, 1987.18(4)

7. Yi yanli, Effect of Magnetic Field on Soil Physical and Chemical Properties, The Chinese Agricultural Science, 1992.2

Author: Zhao xinjun, Vice Professor, Ph.D

Company: Northeastern University

School of Mechanical Engineering and Automation

Address: Shenyang City (110004), Liaoning Province, P.R.China

Phone: 86-024-83683583, 83687630

Fax: 86-024-23906969

e-mail: xinjun_zhao@yahoo.com.cn