A Comparison of Tools Based on the 40 Inventive Principles of TRIZ

Editor | On 01, Nov 2006

Victor E Ross

Institute for Technological Innovation

Faculty of EBIT

University of Pretoria

Hatfield 0002 South Africa

Victor.Ross@debeersgroup.com

Abstract

A comparison was made of four tools that are based on the 40 inventive principles of TRIZ, viz (1) the classic Contradiction Matrix, (2) a 4-Attribute Matrix, (3) a Contradictionless Matrix and (4) the 6 most commonly used inventive principles (Top6). In order to assess their relative predictive capabilities, each tool was applied to a suite of 60 physico-mechanical engineering patents.

The 4-Attribute Matrix is a tool that was developed by re-categorisation of the 40 Inventive Principles in terms of the dominant inventive mechanisms and physico-mechanical system attributes that underpin each. This tool achieved the highest success rate (79%), i.e. in more than three quarters of the cases it would have enabled the inventor to have reached the eventually patented solution. This compared favourably with the 51% achieved by the classic Contradiction Matrix, the 41% of the Top6 and the 32% of the Contradictionless Matrix.

A second parameter, the strike rate, is an indicator of how time-consuming the exercise would have been, and expresses the successful solutions as a percentage of the total number of principles that the inventor would have had to investigate to achieve them. Here, the Contradiction Matrix was most efficient at 26%, followed by the 4-Attribute Matrix with 23%, the Top6 with 12% and the Contradictionless Matrix with 9%.

The product of the success rate and the strike rate provides an indication of the overall usability of each method. It was thus concluded that, of the four tools evaluated, the 4-Attribute Matrix provided the best performance, followed by the classic Contradiction Matrix, the Top6 and the Contradictionless Matrix.

Introduction

The TRIZ invention heuristics is based on the notion that most problems that engineers and technologists face contain key elements that have already been solved in other applications. Inventive principles embedded in a large body of patents have been generalised over many years

to guide inventors and problem solvers in potentially useful directions. The Contradiction Matrix is one of the most popular TRIZ tools, and is the first original instrument that was developed for technical systems that can be in conflict, i.e. have technical or physical contradictions. The classic matrix suggests, for each parameter that is to be improved, up to four Inventive Principles that may help to overcome the associated worsening parameter and thus solve the problem inventively.

Whilst defining a contradiction can often be an important part of resolving it, this can sometimes be problematic, and often it does not lead to a solution. Research by Mann (2002) on a random selection of 130 mechanical engineering patents worldwide has for instance put the overall effectiveness of the classic matrix at 48%. This appears to be a representative average for the particular context in which it was applied and was expressed as the number of principles suggested by the matrix, and actually used by the inventor, as a percentage of the total number of principles used by the inventor (as derived from an analysis of the patents).

Furthermore, due to the fact that an inventive principle has to recur in many high-level patents in various engineering fields before it can become a TRIZ heuristic (according to Savransky (2000, p.221) this figure varies between 10 and 500), for some contradictions the Contradiction Matrix does not suggest any principles. In such a case the inventor therefore may have to try out a fairly large range of options on a number of problem parameters before a solution is attained.

Tools

In order to investigate alternative options that may be available to inventors, the efficiency of the classic Contradiction Matrix was compared to those of three other tools that are also based on the 40 Inventive Principles. These included the following:

4-Attribute Matrix

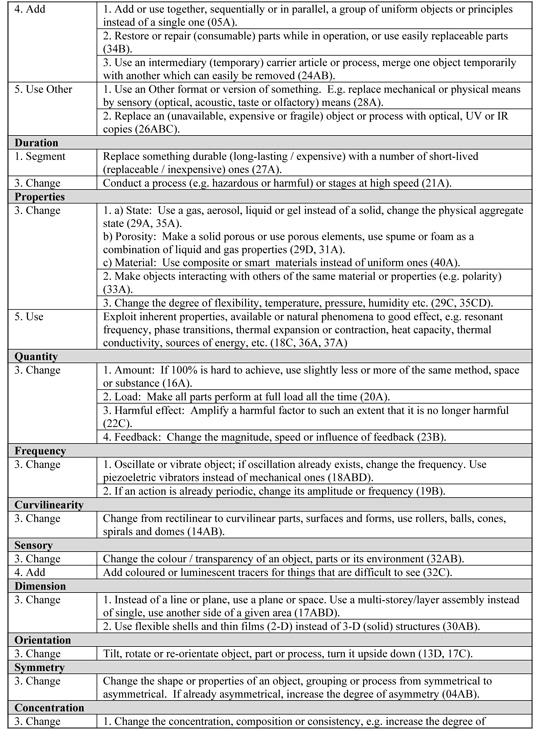

The 4-Attribute Matrix is a tool that was developed by re-categorisation of the 40 Inventive Principles in terms of the dominant inventive strategies, or mechanisms, and physico-mechanical system attributes that underpin them. As shown in Table 1, five such mechanisms have been identified from an analysis of the 40 Inventive Principles (Ross, 2006). These mechanisms have been applied to the attributes of a physico-mechanical systems model, resulting in a new categorisation of the Inventive Principles as per Table 2. A key consideration of this re-categorisation, as should be clear from the Table, was to ensure that each mechanism-attribute pair (referred to as an Ideation Domain) retains a strong conceptual identity. In some instances, a Principle could be categorised into more than one Ideation Domain (the same is true about the way in which the 40 Principles are configured); however, at this stage it was decided against duplication and a Principle was thus represented only in the Ideation Domain with which it was deemed to have the strongest commonality.

The four system attributes that are used most commonly to improve each of the 39 engineering parameters were identified by multiplying the frequency with which an Inventive Principle is used in the Contradiction Matrix to improve the said parameter by the number of times that the Inventive sub-Principle appears in a particular attribute (as per Table 2). The four attributes with

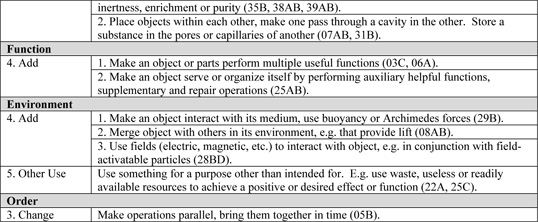

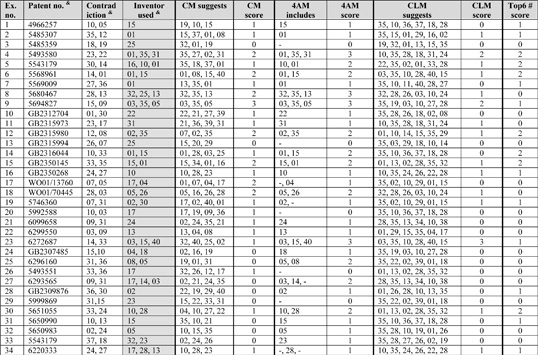

the highest cumulative scores were included in the 4-Attribute Matrix. Table 3 shows the parameters and the corresponding attributes, in decreasing order of priority, that are most likely to lead to solutions.

The 4-Attribute Matrix, being in effect a contradictionless matrix, guides the inventor only according to the engineering parameter to be improved, and not the deteriorating (worsening) parameter as well. Taking for instance example 4 in Table 4 (patent no. 5493580), the parameter to be improved was identified as #23 (Waste of substance). The inventor would use this information to identify, from Table 3, the four attributes that could most likely lead to a solution. In this particular example, these are Object, Properties, Frequency and Duration. A first solution is found in Segment Object (Inventive Principle 01ABC), whilst the second and third matching principles are found in Change Properties (Inventive Principles 35ACD and 31A), e.g. use a gas, liquid or gel instead of a solid, make an object porous or use porous elements, change the degree of flexibility or the temperature.

Contradictionless Matrix (CLM)

As mentioned earlier, potential drawbacks in the use of the Contradiction Matrix seems to be the fact that a contradiction has to be defined and that in a few cases it does not suggest any problem solving strategies.

To overcome these obstacles, Liu & Chen (2001) for instance developed a Contradictionless Matrix which describes, for each of the 39 engineering parameters, the frequency with which an Inventive Principle appears in the classic Contradiction Matrix. In other words, instead of the deteriorating parameter, the inventor now focuses on the frequency with which a particular Inventive Principle is used. As shown in Table 4, for the purposes of the work described in this paper, the 6 most frequently used principles listed by their Contradictionless Matrix for each engineering parameter were employed.

Most frequently used principles (Top 6)

A method similar to the Contradictionless Matrix was devised by simply using the 6 most common Inventive Principles in the classic Contradiction Matrix, namely 35, 10, 01, 28, 02 and 15 (Savransky, 2000, p. 228). The top 6 Inventive Principles were chosen specifically so as to facilitate direct comparison with the Contradictionless Matrix. As shown in Table 4, in each case the Inventive Principles used by the inventor were compared to these ‘Top6’.

Comparison

The predictive capability of each tool was determined by applying it to 60 physico-mechanical engineering patents extracted from the analysis by Mann (2002). The results of the comparison are shown in Table 4.

In each case, a success rate was calculated by expressing the number of matching principles as a percentage of the total number of principles used by the inventors (i.e. 106). [Note: The ‘success rate’ used here is the same as ‘effectiveness’ defined by Mann (2002)] . Likewise, a strike rate was calculated by expressing the number of matching principles to the total number of principles suggested by the particular tool (i.e. 210 in the case of the Contradiction Matrix, and 6×60 = 360 in the case of both the Contradictionless Matrix and the Top6). The strike rate is an indicator of how laborious the application of the tool would be, assuming that the inventor would have exhausted all the suggested principles and not have stopped after a first solution has been obtained.

Whilst the strike rate is straightforward to calculate in the case of the Contradiction Matrix, Contradictionless Matrix and Top6 (all three being based on the original definition of inventive principles), this was more problematic for the 4-Attribute Matrix since each Ideation Domain now involves different sub-principles. For example, as shown in Table 2, the Ideation Domain of Add Object spans sub-principles 05A, 24AB and 34B.

An analysis of the 4-Attribute Matrix (Table 3) indicated that, collectively, the four attributes that are associated with each engineering parameter involve the equivalent of approximately 6 Inventive Principles. This figure was established taking into account the fact that, on average, an Inventive Principle consists of about 2 sub-principles (i.e. 40 Inventive Principles divided into 83 Inventive sub-Principles), but also allowing for deviations from this average, especially by the commonly used principles (e.g. Inventive Principle #35 contains 5 sub-principles, Inventive Principle #28 contains 4 and Inventive Principle #15 contains 3). Thus, an estimate of the equivalent number of Inventive Principles that would have had to be investigated in the 60 patents was put at 6×60 = 360, the same as the Contradictionless Matrix and Top6.

Of the four tools, the 4-Attribute Matrix achieved the highest success rate (79%), i.e. in more than three quarters of the cases it would have enabled the inventor to have reached the eventually patented solution. This compared favourably with the 51% achieved by the classic Contradiction Matrix, the 41% of the Top6 and the 32% of the Contradictionless Matrix under the same conditions. Table 4 also shows that in situations where the 4-Attribute Matrix was not able to match the principles used by the inventor, complementing this approach with the Dimension attribute (namely Inventive Principles #17ABD and #30AB) could increase the success rate for the chosen suite of examples to 93/106 = 88% (refer to examples 17, 19, 20, 26, 27, 34, 39, 47, and 48).

Whilst 60 patents clearly do not constitute a statistically representative sample, it is interesting to note that the Top 6 Inventive Principles achieved a higher success rate than that of the equivalent Contradictionless Matrix. More work in this area seems to be is required to provide a better understanding of the merit and value of the different approaches.

With regard to the strike rate, the classic Contradiction Matrix was most efficient at 26%, followed by the 4-Attribute Matrix with 23%, the Top6 with 12% and the Contradictionless Matrix with 9%. A measure of the overall usability of each method is obtained by considering the success rate in conjunction with the strike rate. As shown in Table 4 by the products of these two factors, this lead to the conclusion that the 4-Attribute Matrix provided the best overall usability, followed by the classic Contradiction Matrix, the Top6 and the Contradictionless Matrix.

Conclusions

The Contradiction Matrix offers the technical inventor a usable method for problem solving. However, the need to define system contradictions can sometimes complicate matters when the inventor knows only the parameter to be improved or in situations where it does not suggest any solutions. In certain cases its effectiveness may also be a factor, recent research in a physico-mechanical context having put this figure at only around 50%.

In order to investigate alternative options that may be available to inventors and problem solvers, the efficiency of the Contradiction Matrix was compared to that of three other tools that are also based on the 40 Inventive Principles. These included a 4-Attribute Matrix, in which the Inventive Principles have been re-categorised in terms of physico-mechanical system attributes, a Contradictionless Matrix based on the 6 Inventive Principles that are associated most frequently with each engineering parameter to be improved, and the 6 Inventive Principles that are used most commonly overall (Top6).

The relative efficiency of the four tools was established by applying each to a suite of 60 physico-mechanical engineering patents. Of these, the 4-Attribute Matrix achieved the highest success rate of 79%, i.e. in more than three quarters of the cases the inventor would have reached the eventually patented solution. This compared favourably with the 51% achieved by the classic Contradiction Matrix, the 41% of the Top6 and the 32% of the Contradictionless Matrix. In cases where the 4-Attribute Matrix was not successful, complementing it with the Dimension attribute increased the success rate to 88%. Whilst the sample of patents was relatively small, the fact that a higher success rate was achieved for instance by the Top6 than the equivalent (6-principle) Contradictionless Matrix suggests that a better understanding of the merit and value of these approaches may be required.

With regard to the strike rate, i.e. a measure of how many principles the inventor would have had to investigate in order to achieve solutions, the classic Contradiction Matrix was most efficient with 26%, followed by the 4-Attribute Matrix with 23%, the Top6 with 12% and the Contradictionless Matrix with 9%. Considering the success rate in combination with the strike rate provides a measure of the general usability of the method. This led to the conclusion that the 4-Attribute Matrix was the most efficient overall. The fact that it involves 25 Ideation Domains instead of 40 Principles may also make it easier to teach or learn.

Further work is planned to also compare the 4-Attribute Matrix with the Matrix 2003 developed by Mann et al. (2003), in which extensive research on present day innovative practices has

resulted in the expansion of the number of parameters and an updating of the priority sequencing of Inventive Principles for each contradiction.

References

Liu, C.C. & Chen, J.L. (2001) A TRIZ Inventive Design Method without Contradiction Information. www.the-trizjournal.com/archives/2001/09/f/index.htm, (Sept).

Mann, D. (2002) Assessing the accuracy of the contradiction matrix for recent mechanical inventions. www.the-trizjournal.com/archives/2002/02/e/index.html, (Feb).

Mann, D.L., Dewulf, S., Zlotin, B. and Zusman, A. (2003) Matrix 2003: Updating the TRIZ Contradiction Matrix. CREAX Press, Belgium, 2003. Referenced in: Mann, D. & O Cathain, C., Better design using nature’s successful (no-compromise solutions).

https://the-trizjournal.com/archives/2006/05/index.htm (May).

Ross, V.E. (2006) A Model for Inventive Ideation in Physico-Mechanical Systems. Ph.D. thesis (unpublished), University of Pretoria, South Africa.

Savransky, S.D. (2000) Engineering of Creativity: Introduction to TRIZ methodology of Inventive Problem Solving. CRC Press LLC, Florida.