TRIZ as a Lean Thinking Tool

Editor | On 07, Feb 2005

Sergei Ikovenko

GEN3Partnets, MA TRIZ, MIT

sergei.ikovenko@GEN3Partnets.com ; ikovenko@matriz.ru

Jim Bradley

International Truck & Engine Corporation

jim.bradley@nav-international.com

Abstract: Lean Thinking is a highly evolved method of managing an organization to improve the productivity, efficiency and quality of its products or services. The core principle it uses is that no work should be done unless it is going to create customer value.

Traditionally Lean tools were Value Stream mapping, Quick Changeover/Setup Reduction, Single Minute Exchange of Dies (SMED), Kaizen, Flow Manufacturing, Visual Workplace/5S Good Housekeeping, Total Productive maintenance (TPM) and Pull/Kanban Systems. Companies and organizations employing these tools report significant gains in productivity and overall effectiveness within their specific entities.

TRIZ Plus can be effectively used as a lean tool to support almost all lean principles as the experience of Kawasaki Steel Group clearly showed.

The ideas behind what is now termed Lean thinking were originally developed in Toyota’s manufacturing operations – known as the Toyota Production System – an spread through its supply base in the 1970’s, and its distribution and sales operations in the 1980’s. The term was popularized in the book “The Machine that Changed the World†which clearly illustrated the significant performance gap between the Japanese and western automotive industries. It described the key elements accounting for this superior performance as lean production – “lean†because Japanese business methods used less of everything – human effort, capital investments, facilities, inventories and time – in manufacturing, product development, parts supply and custom relations.

Lean Thinking is a highly evolved method of managing an organization to improve the productivity, efficiency and quality of its products or services. The core principle it uses is that no work should be done unless it is going to create customer value. Work should be performed in the simplest, most efficient way to maximize the smoothest throughput of product and services from you to the customer. Here is an example. A large truck manufacturing company inspected every returned part from its dealers against initial orders and inventory before a credit would be issued. Implementing this process cost the company millions of dollars each year. The dealers were irate because of the required justification, the time lag and their carrying cost.

The Lean Thinking project of this process showed that the value of 90% of returned parts was less than the cost of the whole process, without even considering the impact on dealer goodwill. The company changed its policy – no returns are checked unless the part exceeds a certain dollar value. As the result the process was dramatically simplified, weeks became days, dealers were happier and profitability increased for everyone .

The core principles of Lean Thinking are based on maximizing customer value and throughput. The faster you can process an order, build a product, or provide a service the less it costs to provide and the happier the customer. Lean Thinking focuses on streamlined work process, reduced inventory, no backlog, maximizing throughput, and eliminating bureaucracy.

Lean companies work to precisely define value in terms of specific products with identified capabilities offered at set prices through a dialogue with their customers. The process involves learning to adopt and employ a series of tools and techniques to achieve incremental improvements in an organization.. Above all, Lean Thinking methods are inclusive of all employees and involve a major change in the embedded attitudes of the individuals that make up the organizations.

Traditionally Lean tools were Value Stream mapping, Quick Changeover/Setup Reduction, Single Minute Exchange of Dies (SMED), Kaizen, Flow Manufacturing, Visual Workplace/5S Good Housekeeping, Total Productive maintenance (TPM) and Pull/Kanban Systems. Companies and organizations employing these tools report significant gains in productivity and overall effectiveness within their specific entities. What about TRIZ? Is TRIZ a Lean tool? In what major principles of Lean could TRIZ help? Which of those 7 types of Muda (wastes) can TRIZ address?

TRIZ (Theory for Inventive Problem Solving) is one of the most powerful inventing methodologies, a scientifically-based and empirically-derived method that originated for the analysis of the world patent collection. Its strongest side is in the Conceptual Stage of design, while the Analytical Stage is not completely and effectively covered, at least in what is known as classical TRIZ.

Value Engineering Analysis (VEA), Root-Cause Analysis (RCA), Flow Analysis (FA) and several other engineering methods developed at different times offered exceptional analytical approaches, but lacked concept generation techniques. Merging these analytical methods with TRIZ gave birth to several integrated methodologies based on TRIZ : ITD, TRIZ Plus, I-TRIZ. An integrated method that intimately combined these analytical tools with the inventive power of TRIZ has a definite advantage and a potential and can be effectively used in organizational methods like Lean, Six Sigma, TQM, etc.

So where exactly, at what stages of Lean could, say, TRIZ Plus be used? Womack and Jones (1996) describe the business environment within which they saw Lean techniques being successful . Five key principles emerged:

• Value

• Value Stream

• Flow

• Pull

• Perfection

Value. The customer is the only reason why businesses exist, therefore an understanding of what the customer actually requires is an essential element of the strategy of a lean organization. The value, defined from a customer’s perspective, is then aligned within the organization and value-adding activities can be recognized as any activity that the customer is happy and prepared to pay for. A general estimate for a typical manufacturing firm is that value-adding accounts for less than 5% of the total time a material is at the factory. It is horrifying to think that remaining 95% of the time is spent adding costs (storage, delaying at queues within the factory, transportation between the stages of the process, etc.). Even more frightening still is the knowledge that such wastes are present at every supplier, customer and distribution point as the product moves towards the actual consumer and that many other types of “Muda†(wastes) have actually been “designed into†the internal and external material flow process.

In the practice of consulting projects, it is often necessary to adopt a product focus. Product focus enables a long-term dialogue to be started concerning the nature of value and how the product delivers it. More explicitly, the fact is that the client requires a product to suit his purpose and provide value for money. What the client is less concerned with is how the product is developed and how many people are involved in it. One rarely thinks about the suppliers to a production line when buying a car.

Now let us look at the approach to value in TRIZ Plus. Steps of its analytical stage – component analysis, function analysis, diagnostic analysis – in the long run have the same objective: to determine the value of different operations of the process or components of the product. The analysis results flag those functions that are of lower value ranking them accordingly.

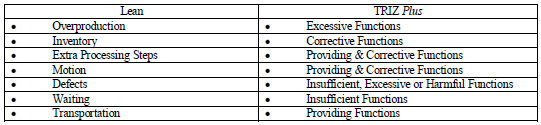

The traditional Lean seven types of Muda are:

• Overproduction

• Inventory

• Extra Processing Steps

• Motion

• Defects

• Waiting

• Transportation

Using the terminology of TRIZ Plus analytical approach in our function model of a process we will have:

The results of diagnostic analysis will clearly show the value landscape of the manufacturing process, fully supporting Lean Value Principle.

Value Stream. Once value has been specified, the next step is to identify the value stream. The value stream identifies all those steps required to make a product. The traditional key technique behind the value stream is that of process mapping. However, it is process mapping for a very specific reason – to understand how value is built into the product from the point of view of the client. At a strategic level it offers a perspective on defining what is to be done. At a more tactical level the value stream mapping can be used to identify where Muda lies in a particular operation and how the operation can be performed more effectively. The value stream map is used to both illustrate the “current state†and the desired “future state†of the process. The map highlights the seven types of Muda mentioned above and is used to provide a basis for developing plans to implement lean tools and techniques.

Following the same analogous pattern, TRIZ Plus tools that can be used here:

Product Family Matrix can be used to enable the organization to re-align its focus from functional to Value Stream.

Flow. Lean organizations are primarily concerned with making materials flow in the system with high levels of stock turn without allowing the material to idle in queues or stagnate at large stock points. The ability to ensure materials flow within a factory and derive value rather than cost, involves the eliminations all types of Muda. Flow is defined as producing a product from raw material to completion without unnecessary interruption or delay (that is, Muda). The goal is to achieve single-piece flow in each process, ensuring work flows smoothly from one stage to the next, one at a time, increasing flexibility. As a result, we will get reduction in work in progress, part movement, parts handling, quality defects and therefore, the lead time.

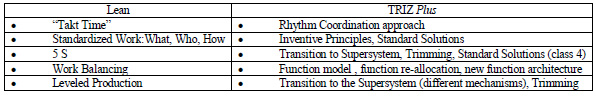

The key objective of Flow is to align the processes to suit the customer requirements, thus reducing waste in the system. The key tools for implementing Flow are:

• “Takt Timeâ€

• Standardized Work

• 5S

• Work Balancing

• Leveled Production

Though there are traditional normative methods to apply these tools, a Lean project will get into a totally different perspective when a number of TRIZ concepts are used here:

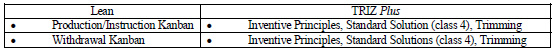

Pull. At a strategic level Pull really identifies the need to be able to deliver the product to the customer as soon as he needs it. This principle derives from Toyota’s innovation, the Kanban. The Kanban is a tool that communicates specific production/withdrawal of parts information to the upstream process. The Kanban applies for the lean approach where Flow cannot be used to move materials between departments or processes. At these points it is important to have materials available when required and these key buffers effectively disconnect the internal (or external) customer and supplier operations. The supplier manages then is such a way that withdrawals of products by the customer trigger the manufacture of replenishments. Thus as products are taken to demand , the empty space left by withdrawal provides the “requirement†to replenish.

The traditional Kanban may take a form of a card, footprint, empty bin, etc. However Pull approach with be much more ideal if a number of TRIZ tools are used:

Perfection. Once an improvement has been made, it must now become the standard for the process.

Adhering to this standard will ensure that the problems experiences in the past do not occur now or in the future. It is important to understand that transformation to Lean is a continuous improvement process. This is a key concept at the strategic level, so TRIZ tools cannot be applied directly, however some Inventive Principles and Standard Solutions are appropriate here.

For business executives the implications of Lean approach are numerous and broad ranging. One of the first lessons of Lean Thinking is to understand the applications of five lean principles to your business, its key customers and suppliers. The application of the approach will be influenced by a number of factors. The implementation and deployment of Lean Thinking within an organization will be more sustainable is the Lean approach is supported by an effective set of tools such as TRIZ Plus.

TRIZ Plus approach has been used in a multimillion dollar lean project at Kawasaki Steel Group, where at different stages of Lean a number of above-mentioned TRIZ Plus tools generated dramatic results including simplification of the process, considerable cost reduction, reliability and safety improvement.

References

Naomi Garnett and others, 1998, Proceedings IGLC ,“Strategic Application of Lean Thinkingâ€, Mallock.

Sergei Ikovenko, Nauri Minouki, 2002, Proceedings JFE, “Lean in Blast Furnace Project – Mizushima- Chiba 6 â€, Kuomo.

Nick Rich, An Executive Guide to Lean Thinking, Deloitte & Touche, 2001

James Womack, Daniel Jones. Lean Thinking. 351 p., Simon & Schuster, New York, 1996