Solving Technical Contradictions in Construction with Examples

Editor | On 14, Jul 2005

Abram Teplitskiy, Ph.D., Scientific Consultant

Roustem Kourmaev, President

Advanced Technologies International, Inc., Richardson, TX

tepl@sbcglobal.net

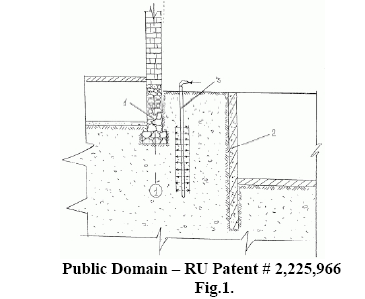

In our first article for TRIZ Journal we analyzed application of 40 Inventive tricks in Construction (1). But Theory of Inventing Problem-Solving (TRIZ) gave inventors and engineers another unique approach for advancing technical systems. It is based on envisioning an ideal solution of a problem, identifying contradictions between the ideal solution and real conditions, and finding resources in a system to resolve these contradictions (2). We will start our “travel†in the country of contradictions with a simple problem – how to test soils under foundations of a building. In Fig.1 you can see a sketch of a foundation with some structures. Now imagine that builders faced a problem – how to investigate geotechnical properties of soils under foundation, for example under the footing 1.

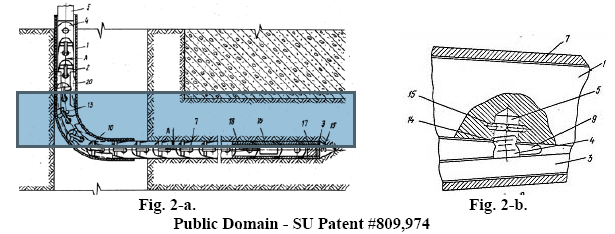

Readers should agree that it is a complicated engineering task. Let’s start with postulating the ideal solution for this problem. To get under the foundation from outside the building area we should imagine an ideal device, which could perform following operations: be inserted vertically in the soil up to the depth of interest, then turn, and finally continue inserting horizontally. For solving other problems the ideal device could turn once more and continue second step of vertical (or at any other direction) inserting, and so on. By analyzing this vivid picture, we should suppose that such device is a compound of chain elements, which are connected pivotally, and have second controllable connection between elements. While making the first vertical insertion, all the connectors are inserted, and the chain is rigid, so that the device could be inserted to necessary depth. Then the controllable chain connectors should be sequentially extracted from the chain elements during continuous insertion, and after completing the “turn†inserted back in the chain elements for facilitating the horizontal part of the inserting route under the structure. Of course, a measuring device, like nuclear gauge, for measuring properties of soil is at the end of this compound of chain elements. We invented different types of chain connectors for realizing such ideal solution. One of the simplest types of such “connection-disconnection†devices is shown in the Fig.2.

Rigid elements of a chain are connected pivotally, placed in a bended pipe (Fig. 2-a), which provides change of vertical movement to horizontal movement. Each element of a chain also has second controllable connector with neighboring element. In a version shown in the Fig.2.b controllable connector is button-like, and can be pressed inside the hole by pressure of wall of a directional tube. While moving in opposite direction, the button-like connectors are extracted from the neighboring chain elements, and returning the flexibility to chain elements, and, as result, movement through directional elements. When this button is “closedâ€, two neighboring pieces of a chain became rigid, and we need only a mechanism, which extract button-like connectors and press them back after turn is over. Here we described only main ideas of such “rigidity-flexibility†transformation, details could be found in original descriptions of cited patents (3). By the example above we see the resolution of the “rigidity-flexibility†contradiction by separating contradictive features in time.

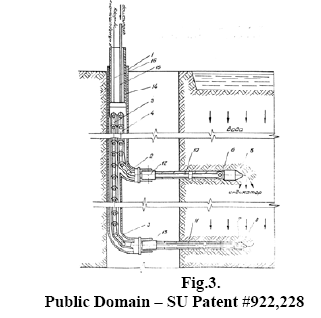

Now let’s see how a productive idea like above could be applied for solving different problems, and we will illustrate this by our inventions, mostly in underground construction area. First problem to solve is how to measure permeability of soil using only one vertical boring, because it’s necessary to follow up water at two levels. Picture below illustrates a solution: in the case of permeability we need to insert two gauges on two different depths, one under another as shown in Fig.3.

Another problem, which could be solved by separating contradictive features in time and using above type mechanisms, is connected with installing different strengthening systems for foundation, for example concrete-rebar systems. One of developed technologies includes inserting under foundations a linear rebar lines, anchoring these rebar lines at soil, than while taking out the inserting equipment, by rotating a spindle coils around this longitude rebar and welded them together in several places. Then concrete should be pumped along this rebar system to complete the process. SU Patent # 863,769).

Opportunities to install under foundations systems of reinforced concrete curvilinear elements (using tools like shown in Fig.5) made possible diversifying structures of foundations undergoing reconstruction, for example like shown in Fig.6.

By applying above structural solutions for big industrial buildings, inventors got an effective solution for controllable foundations like one shown in the Fig. 7. In a case when equipment placed on the floor of such industrial building would change, this will coarse changing the distribution of load on foundation and may coarse necessity to reinforce the foundation. In the case when the foundation has controllable reinforcing system like shown in Fig.7, the adjusting to new load could be done by strengthening the reinforcing lines as described in SU Patent 1,265,247.

Besides foundations, curvilinear elements also could be used for anchoring retaining walls. According to SU patent #1,303,672, anchors could be made as flexible metal belt, and bend like a loop, which follows a screw surface, cylindrical surface, or even have surface like Mobius strip, etc. In a case of making anchor like a Mobius strip, the pressure acting on different sides of a strip make stresses compensated due to one side character of Mobius strip.

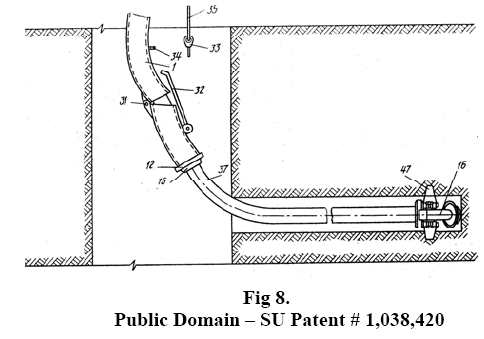

Similar technique was developed to install in soil flexible horizontal or inclined draining systems, as described in SU Patent #1,038,420 (Fig.9). Drainage pipes for such installation need to be flexible, with arrowhead with anchor. After anchoring, the equipment should be taken out of made curvilinear channel, and empty space should be filled with draining material (4).

Besides installing horizontal drainage from vertical borings like shown in the Fig.8, such curvilinear approach could be used for ray-like drainage systems, which contain horizontal drainage lines installed from the cylindrical wells along or/and under structures in need of drainage protection: big dams, embankments, depositories of ore tailings, etc. To reduce the number of pumping stations we developed some technologies of connecting neighboring wet wells using some new approaches. After the wet wells were already erected, it is possible to drill curvilinear boring starting from the bottom of the wet well to the dry surface using technology shown in Fig.9. For this purpose the drainage tube is connected to a self-propelled pneumatic machine called “pnevmoproboinik†with inclining wings. While the “pnevmoproboinik†is moving, it follows a curvilinear trajectory and finally reached the surface. Another “pnevmoproboinik†by same way came to the surface from another wet well. On the surface ends of these two steel cables are connected, and are used to sawing through the tract of soil between surface of the soil massive and the bottom of the wet wells. Finally, the horizontal segment between the wet wells should be connected by a flexible tube, and as result two wet wells became hydraulically connected, and water could be pumped out from these two wet wells by using only one pump.

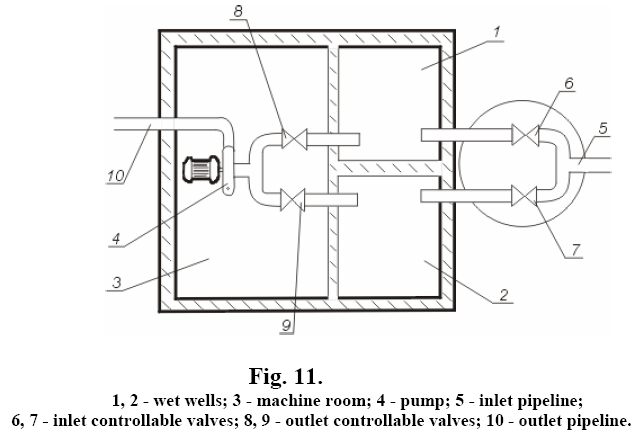

To complete the “wet well†topic, consider another method of connecting wet wells by filtration. The technological scheme of this method, called in inventing “selfservice†trick, is shown in the Fig. 11, and could be championed as the most ideal method of connecting two wet wells. Notice, that to make this self-service drainage working well, it is effective applying vacuum to lower drainage line. So, the system resource used in this solution is ability of the soil to filtrate water, and this resource is exactly where we need it – in soil!

Above, as example, we discussed ways of solving “rigidity-flexibility†contradiction by using our inventions. Most of above problems were solved by separating contradictive features in time: at one time interval chain elements are rigid, during another interval the elements are flexible. In TRIZ literature readers could find detailed classifications of methods for resolving technical contradictions in different systems, and fragment of such classification is shown below (2).

1. Separation of Contradictory Properties in Space

1.1 Separate the object into parts, giving parts contradictory properties. Example: Lift Station with Wet Well, which is separated in space in two parts. Pumping out from these two separate wet wells is organized in turn.

1.2 Take advantage of the available spatial resources: available space, other surfaces of objects, stacked layout, placement of one part inside another. It is possible to stack above-described two wet wells one inside another.

2. Separation of Contradictory Properties in Time

2.1 Divide the time of use into intervals, assigning the system different properties at different times. Example: Using ice “solid state†condition during while installing drainage elements, and using “liquid ice†– water condition during second time interval while exploiting drainage in old pipelines.

2.2 Perform helping functions or parts of the main functions before or after the main function.

3. Separation of Contradictory Properties by Phase transition

3.1 Take advantage of the “double” state of the system (transition from one phase to another) Example: Transition from “solid†state of bentonite slurry to “liquid†state of bentonite slurry to realize new method of laying pipelines.

3.2. Switch the single-state material to a multi-state material. As first example of separating contradictive features in space we will discuss one of our favorite inventions – lift station for sewerage with accurate determining of amount of pumped water (1).

Wastewater from customers is collected using lift stations. The amount of wastewater pumped through lift station, mostly is determined by monitoring the level of wastewater in the wet well. But under high inflow rates, pumps started to work continuously, and above method become not accurate. Applying TRIZ approach, we can postulate that in this measuring system, from one side, for precise measuring of volume of wastewater pumped through lift station, there have to be no additional inflow in the wet well; from other side, pump have to pump out wastewater continuously. From analysis of this situation, we can conclude that we get two contradictive requirements: it will be no inflow, and it will be continuous inflow of wastewater. Here we’ll see how TRIZ works. The main idea of resolving contradictions is separation contradictive requirements in time or in space. In this case, we applied separation in space principle.

After we got an idea, it will push us automatically to reasonable solution, using algorithms developed in TRIZ. Let’s discuss shortly, what means separation in space principle. According to lift station problem, it means that processes of inflowing wastewater and pumping wastewater have to be done spatially separate in every act of pumping (5). One more step, and we’ll picture a lift station having two separate wet wells as shown in the Fig.12.The developed lift station operates in the next way. Sewage starts to inflow in the wet well 1 through inlet pipeline 5 and through open valve 6. At this time, the controllable valve 7 is closed. During filling the wet well 1, the level of sewage reaches the upper level gauge. A signal from upper level gauge enters the controlling system. After entering of this signal, controlling system closes the controllable valve 6, and opens the controllable valve 7. Therefore, sewage begins to inflow in the wet well 2 through the controllable valve 7. In the same time, controlling system switches on the pump 4, which is placed in the machine room Pump 4 begins to pump sewage from the wet well 1 through pipeline, valve 6 and outlet pipeline 10 in sewerage. While pumping out the wet well 1, sewage fills the wet well 2. Signal about switching of the pump 4 came from the controlling system to the counter.

During the pumping process, the level of the sewage becomes lower and reaches the lower level gauge. The wet well 1 is empty, and ready for next filling. After the wet well 2 are filled completely, a signal from the upper level gauge enters the controlling system.

After entering of this signal, controlling system closes valve 8, and switches on the pump

4. During filling the wet well 2, the level of the sewage reaches the upper level gauge, and the cycle repeats. The process of filling and pumping of the wet wells 1 and 2 continues by turn. Signals about each switching on of the pump 4 enter the counter, which counts the quantity of switching on of the pump 4. The quantity of pumping sewage during given time, could be determined by formula:

Vt = V1 * N1 + V2 * N2, (1)

Where: Vt – the amount of sewage, pumped through the lift station in time interval T;

V1 – the volume of the first wet well;

N1 – the amount of switching of the pump for pumping from the first well;

V2 – the volume of the second wet well;

N2 – the amount of switching on the pump for pumping from the second well;

If the volumes of both wet wells are equal, the formula (1) will have a simpler look:

Vt = V * N, (2)

Where: V – volume of wet well; N – amount of working cycles of a pump.

Wet well’s volume could be metrologically certified to guaranty the accuracy of measuring the amount of wastewater transported from each customer to wastewater facilities.

In above lift station case we used structure resource – we separated one wet well in two Equal parts, and organized filling them in turn, providing exact and the same volume of wastewater for every pumping cycle.

As another example of separating contradictive features in space we will discuss utilization of inverted surfaces, in other words, how to use other side of elastic tube. As introduction for such technologies let’s discuss a problem of repairing a pipeline from a manhole. Imagine that you introduced in horizontal deteriorated underground an elastic pipe. But how to move this pipe inside a host pipe, and in the same time glue it to the internal surface of pipeline under restoration? What kind of a contradiction we faced in this case? We have a tubular line underground, and we need to “insert†another tubular element inside the first one to restore the ability of pipeline to carry through any liquid substance. We can start to do it from any end of old pipeline, but in both cases we need to install the new element over and ahead of already laid elements. It means that we faced next type of contradiction – between monolithic (already laid element of a new pipe) and non-monolithic (before becoming a part of pipeline). One of first ways to solve this contradiction, which authors found, was a spatial resource – to wind spiral strip with direction of winding over and ahead of the monolithic part of existing pipeline. But in these times was developed more effective method, which used another spatial resource, we can say another geometrical resource – usage of inverted pipes, or simply saying, other side of the tube!

If you can propose your own versions, you have natural gift of how to use spatial resources. If you don’t, look on the following picture.

Method is based on insertion of a hosepipe 6 made from elastic fibrous material inside the host pipe; hosepipe is soaked by impregnated polymer material. Ready flexible polymer hose is inverting and advancing in the host pipe, pressed to inside surface by pressure of fluid with subsequent setting and polymerization. Inverting, advancing of the hose, its unfolding and pressing to internal surface of the host pipe is accomplished by using air-pressure, and pressure of water stand. Optimal pressure by water stand h for advancing of a hose can be estimated by following formula h = 3 + 0,5/d, for full lining and pressing to internal surface of host pipe it is recommended to use water stand h = 6 + 0,2/d, where h – height of water stand, meters, d – diameter of a pipe, meters, and 3 and 6 constant coefficients.

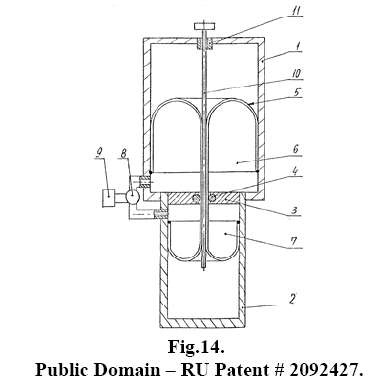

Method was originated by Mr. Wood with Insituform International Company for repairing underground pipelines without digging the ground and disturbing the traffic. Later applications this method were diversified by using innovative materials, and technology was advanced, now inversion technology is regular in pipeline industry. We wanted to present here some untypical cases of inversion technology usage. First is application of inversion technology to extinguish a fire. In the Fig. 14 you can see a scheme of a device for fire extinguishing.

Fire extinguisher by RU Patent #2,076,053 contains a case 1, capacity 3 made from elastic material to carry fire extinguishing liquid 4. Capacity 3 is made in a form of inverted hose, and on the inverted end a head with holes, which is connected to a head 2 by hanger bracket with a lock. In a case of a fire, the hanger lock is open, and water freely and quickly pour out the capacity. Here we should mention that this invention was made by V.V. Shishkin who can be called Russian Federation Champion in creating different inventions based on the Inverted Hose idea. You can find his inventions in Russian Federation Patent Office database www.rupto.ru. Now we’ll see another application of the “inverted†hose trick, which could be applied not only in construction, but also in any branch of human activity. It is a pneumatic-lift by RU Patent # 2092427.

This invention realizes a simple principle of vertical lifting of different weights. Lifting device is a chamber divided by a partition 3 in two equal parts 1 and 2. An elastic hose 4 passed through the partition 3. Ends of the hose 4 are inverted and fastened to corresponding parts of a chamber in both sides of a partition. A rod is installed between the empty chambers.

Now we’ll return to solve technical contradictions by dividding them in time. We will consider a problem – how to install drainage material in old pipelines without digging trenches. On one chemical plant, the level of groundwater raised, and started to cause instability of foundation system. Experts recommended implementing underground permanent drainage. One proposal was adopted as highly cost-effective – use old deteriorated pipelines as basis for new drainage system. Technological entrance to these old pipelines could be from manholes, so the only one problem remains –how to place sorted granular filter material in the lengthy underground pipeline keeping stable the quality of construction works. Using TRIZ approach, specialists postulated Ideal Final Result: filter material has to become drainage by itself, after being inserted in old pipeline. The contradiction in this case is as follows:

• Filter sorted material during process of its insertion has to be monolithic to provide smooth insertion;

• After insertion, filter material has to become granular to insure the drainage quality of a new structure.

Because of the contradictory requirements are applying to “future†drainage in different times, TRIZ recommended using separation in time principle. After formulation this contradiction, the solution came, we can say, automatically: sorting the granular material in necessary order, forming cylindrical blocks, fill them with water, and then … frozen! Frozen blocks will have mechanical strength, and could be easily inserted in pipeline. Cylindrical shape of blocks guaranties the quality of blocks connection in old pipeline. During some technological time, ice will melt, and granular filling of pipeline will work as perfect drainage. The scheme of this drainage installation method is shown in Fig. 15.

To improve the quality of drainage, we proposed during freezing the drainage block with prestressed metal spring. Drainage block with compressed metal spring is shown in picture Fig.16. After installing such drainage blocks they will melt during time, and drainage will work as complete line. In this example readers can see that process of installing of drainage is separated from time when it will start to work by some technological time (time of ice melting) – than is real time of separating actual contradictions in solving this problem.

Next big “department†of methods of solving technical contradictions is based on switching from one possible state of the material to another. Take advantage of the “double” state of the system (transition from one phase to another), like above-discussed with ice-water transition. We will show how to use for solving problems transition from liquid state of bentonite slurry to its solid state.

Imagine ideal technology of laying pipelines: you assemble pipes on the surface of the trench, and then a magic – assembled section lowers on the bottom of the trench by itself. Such “ideal†technology could eliminate presence of workers on the bottom of the trench in general. Way from “ideal†technology to “real†includes finding resources to realize ideal version in durable technological steps. We developed so-called conveyer technology of pipeline laying, which include two versions. First version rose from laying pipelines in tunnels. For this purpose, pipelines was proposed to assemble using conveyer principle: pipes were connected one after another, joints between pipes were tested, and connected pipes was consequently hanged on monorail system, and than advanced by monorail in tunnel. After all sections were assembled and advanced, hangers on the monorail were synchronously elided on the bottom of tunnel. So, ideal result was successfully realized. {it is not clear what existing resources were used—this sounds like you added new things}

In the case of the trench, however, we have another problem to solve – the stability of the trench in time, especially with high level of water table in the soil. But it is already a standard technology to work in such conditions – filling the trench with bentonite slurry. In these conditions, assembled pipeline will dropping in trench filled with slurry, and will rest on the bottom of the trench. Bentonite slurry could be pumped out the trench, and be used in other processes. Another version of a conveyor principle is based on assembling and advancing pipes by the day surface of the trench filled with bentonite slurry (7). In this case, bentonite slurry, having thixotropic properties, will keep assembled pipes in horizontal plane as solid body, and will facilitate advancing the assembled pipes horizontally. After assembling all pipes in a section, testing joints between pipes, assembled sections of the pipeline could be lowed on the bottom of the trench by simple pumping out the bentonite slurry. Notice, that in this case thixotropic bentonite slurry has properties of a liquid, and keeps horizontality of its surface while pumping, in this way preventing any inclination (5). This technology is illustrated in Fig.17.

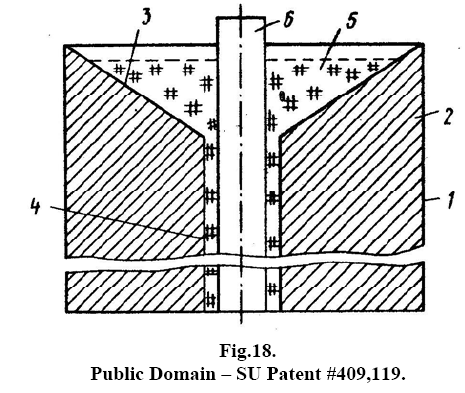

Above example of using transformation of states of bentonite slurry is very simple, and is based on the ability of this material to absorb big amounts of water. At first we used such absorbing ability to calibrate nuclear gauges in big range of moisture content of soil – practically from 0% to 100% (Volumetric %). Than we invented a simple method and equipment for providing such calibration, sketch of which is shown in the Fig. 18. For calibration we used the combination of bentonite slurry with different amounts of sorted soil (4).

Such equipment is effective in cases when you need to recalibrate nuclear gauges to measure density and moisture content for soil when boring conditions for testing soils changed.

You can find many other examples of solving contradictions by doing patent searches on the World Wide Web, including www.uspto.gov, www.delphion.com.

www.rupto.ru, and other databases. We hope that the examples in this article taken from patent databases will convince you to do such research.

References:

1. Abram Teplitskiy, Roustem Kourmev, Application of 40 Inventive Principles in Construction, TRIZ Journal, USA, May 2005, www.the-trizjournal.com

2. Altshuller G. (1999). “The Innovation Algorithm: TRIZ, Systematic Innovation and Technical Creativityâ€.

3. Roustem Kourmaev, Abram Teplitskiy, Application of Inventing Problem- Solving Theory (TRIZ) In Pipeline Technologies, Proceedings of International Conference in Pipelines, Baltimore, Maryland, 2004.

4. Abram Teplitskiy, Technology of Soil Compaction Quality Control, Kiev, Publishing House Budivelnik, 1985, 73 pages (In Russian).

5. Abram Teplitskiy, “Complex Mechanization of Pipeline Layingâ€, Publishing House “Budivelnikâ€, Kiev, (1989), 144 pages (In Russian).

6. AbramTeplitskiy A. et al. (1998). “Method and Equipment for Assembling and Laying Pipelinesâ€, Russian Federation Patent # 2,123,630.