Patent of the Month – Graduated Auxetic Foam

Editor | On 10, Oct 2018

Darrell Mann

Our patent of the month this month sticks to the world of ‘keep-it-simple’, and also manages to stay local. My old haunt, Rolls-Royce in Bristol to be precise, and a pair of inventors who had US9,956,729 granted to them on May 1st. Regular readers will know that auxetic (or negative Poisson’s Ratio) materials has long been one of our favourite technologies, and one we mention wherever we go, usually in the vain hope that someone will finally find a way to make positive use of the unique capabilities the novel material structure offers. One of the stumbling blocks we’ve observed has related to the difficulty of manufacture of structures containing just the right auxetic properties. One of those ‘just right’ properties being the ability to engineer the right level of negative Poisson’s ratio at different physical positions. Graduated auxetics has thus become one of the ‘holy grail’ targets of prospective auxetic material designers. Now, thanks to the Rolls-Royce invention, it looks like we have what is needed.

Here’s what the RR engineers have to say on the problem at hand:

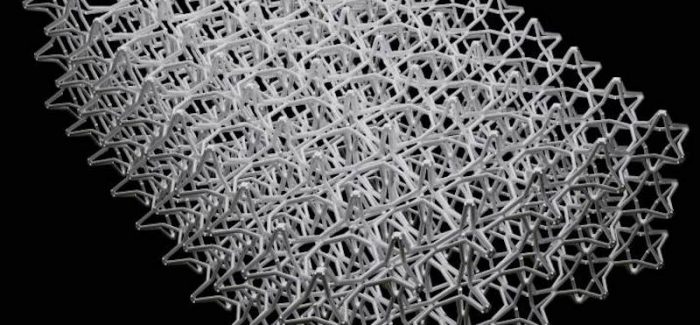

Materials having a negative Poisson’s ratio, when stretched, become thicker in a direction perpendicular to the direction of the applied force. This behaviour is a consequence of hinge-like structures within the material which flex when stretched. Materials which display a negative Poisson’s ratio are often referred to as “auxetic” materials, and have very different properties to non-auxetic conventional materials having a positive Poisson’s ratio. Auxetic materials have mechanical properties characterised by high energy absorption and high fracture resistance, and are also highly absorbent.

It is known that auxetic materials can be manufactured from open-cell foams such as open-cell polyurethane foam. Open-cell foams are foams in which the cells are not closed, but communicate with one another through openings in the cell walls. The cells can be considered to be defined by ribs rather than walls such that the cells create a network of interconnected pores within the foam.

WO9925530 describes a method of manufacturing auxetic foam in which a piece of low density open-cell polyurethane foam is first placed within a mould. The mould comprises sets of opposing plates which are moved towards each other to compress the foam in three orthogonal directions. Compression of the foam causes the ribs of the cells to buckle. The foam is then heated under compression to a plastic or semi-plastic state which causes the ribs to become permanently deformed. The foam is subsequently cooled to set the ribs in their deformed state thereby creating a foam in which the cells have a re-entrant structure. It is this re-entrant structure which provides the hinge-like structures that give rise to a foam having a negative Poisson’s ratio.

There are perceived to be potential advantages to an auxetic foam having a Poisson’s ratio which varies across its extent. For example, certain applications for sound proof panels, acoustic linings, duct liners, vibration mat pads and filters could be improved if such an auxetic material could be provided. However, heretofore there have not been provided any suitable methods to produce such a foam.

It is a preferred object of the present invention to provide an improved method of manufacturing a foam, and more particularly to provide a method of manufacturing a foam having a Poisson’s ratio which varies across at least a region of the foam in a gradient distribution.

Here’s how we might best map the basic contradiction needing to be solved onto the Contradiction Matrix:

And here’s how the inventors solved the problem:

A method of manufacturing a foam having a varying Poisson’s Ratio, the method comprising the steps of: a) providing a housing defining an internal space having at least one inlet aperture and an outlet aperture, the inlet and outlet apertures being in fluid communication with the internal space and spaced from one another across the internal space; b) providing an open-cell foam of a size and shape configured to fit inside the internal space of the housing; c) positioning the foam inside the internal space of the housing; d) establishing a flow of air through the foam via the inlet and outlet apertures, such that the local pressure within the foam varies with increasing distance from a value at or near the inlet aperture to a higher value thereof at or near the outlet aperture; e) heating the foam to a predetermined temperature whilst maintaining said flow of air through the foam; and f) subsequently cooling the foam whilst continuing to maintain said flow of air through the foam, wherein the Poisson’s ratio of the cooled foam varies with increasing distance from a value at or near the inlet aperture to a lower value thereof at or near the outlet aperture.

Spot the Inventive Principles?

29, Fluid (‘a flow of air through the foam’) and 12, Equi-potentiality (in reverse) (‘such that the local pressure within the foam varies with increasing distance from a value at or near the inlet aperture to a higher value‘). Simple when you know how.