Investments – Rotational 3D-Printing

Editor | On 25, Jul 2018

Darrell Mann

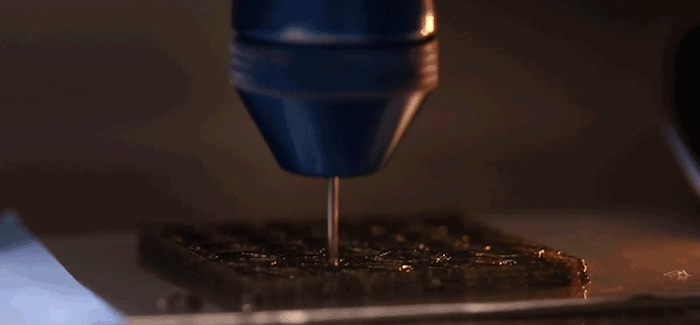

Harvard engineers have demonstrated a new 3D printing technique that allows the arrangement of short fibers in the printed material to be finely tuned. The spinning printer head gives the technique the name “rotational 3D printing,” and according to the team the fibers in the ink can be arranged in different orientations at different parts of the printed object, in order to boost its strength, stiffness and resistance to damage.

3D printing is emerging as a powerful tool for lowering the cost, materials and know-how for manufacturing, by depositing layer after layer of “ink” to build up an object. But the maximum resolution of these printers means that the microstructures of the material often can’t be directly controlled. To strengthen a particular part of the object, for example, a normal 3D printer might need to just drop more of the material in that spot.

Rotational 3D printing, on the other hand, is designed to let users configure the properties of individual areas of an object by tweaking the microstructures. The spinning printer head will send streams of the ink in a given direction, lining up the micro-fibers in a way that makes them more load-bearing, or better able to resist damage. Better yet, it saves material compared to the approach of just dumping more in a given spot.

“Rotational 3D printing can be used to achieve optimal, or near optimal, fiber arrangements at every location in the printed part, resulting in higher strength and stiffness with less material,” says Brett Compton, co-author of a study describing the technique. “Rather than using magnetic or electric fields to orient fibers, we control the flow of the viscous ink itself to impart the desired fiber orientation.”

With this system, during the software planning process users could pinpoint which parts of an object need to be reinforced, and the rotational 3D printer would take care of the rest. While the current prototype worked with an epoxy composite matrix, the technique could be applied to any ink material used in any 3D printing hardware.

“One of the exciting things about this work is that it offers a new avenue to produce complex microstructures, and to controllably vary the microstructure from region to region,” says Jordan Raney, co-author of the study. “More control over structure means more control over the resulting properties, which vastly expands the design space that can be exploited to optimize properties further.”