Converging in Problem Formulation : A Different Path in Design

Editor | On 10, Dec 2002

By: Denis Cavallucci and Philippe Lutz

Denis CAVALLUCCI

denis.cavallucci@ensais.u-strasbg.fr

Philippe LUTZ

Philippe.Lutz@ensais.u-strasbg.fr

Dmitry KUCHARAVY

daknet@iname.com

Laboratoire de Recherche en Productique de Strasbourg (LRPS)

ENSAIS

F-67084 STRASBOURG Cedex

tél. : 03 88 14 47 00

Fax : 03 88 14 47 99

ABSTRACT

The efficiency of the design process in companies today is largely dependent on the skills of individual members of project teams, the capacity of the software available on the market and any assistance provided by the tools and methods found scattered around the industrial world. Within this context, there have been myriad attempts to optimize the different stages in the design process by using computerization, but a growing proportion of current research work on design tends to agree that the crucial point in the act of designing lies in the phase where inventive ideas are sought and that without such ideas being generated, there is no successful future for the product. In the framework of a large number of research activities it has been proven that the TRIZ contribution to the science of design has a promising potential [1-2-3-4] . On the other hand, the added value and spectrum of problem typology where TRIZ could help remains unclear for most researchers for various reasons. Originally, since the theory has penetrated the so-called occidental world, every individual took from TRIZ what he thought was right according to his own knowledge about design, problem solving process, creativity or needs forgetting that 95% of scientific literature about TRIZ’s fundamentals was written either in Cyrillic or in unpublished manuscripts. In most cases, theses multitudes of uses did not see that the original idea of TRIZ was to formulate a theory as strong basement for building methods and tools to satisfy designers expectations. This fact led nowadays TRIZ’s image to fuzziness since available literature on the subject only presents case studies and uses of tools (mostly the matrix) although TRIZ’s scope is much wider. To avoid further aggravation of this fact, this paper aims at presenting the first axiom describing TRIZ’s objectives as a basement for our research activities. Two methodological approaches are then presented : the “trial and error” type approach, which is still very much in use everywhere in industry and which aims to explore an area of solution-seeking, following a structural approach or not, through a series of attempts, which often end up in failure. The second approach is the “convergent” approach proposed by the TRIZ body of knowledge and developed as a contribution to design activity’s efficiency in our research center. This approach aims at limiting the sphere of research during a larger and longer problem statement stage to converge towards a small number of solutions in opposition to traditional approaches which consists in generating a large amount of ideas and select the best suitable ones to be implemented. A case study on the internal ventilation of a car will also be presented to illustrate the quality of the results that could be obtained when applying this convergent approach.

1. INTRODUCTION

All researchers and industrialists who have analyzed the rules of the new economy agree that the added value for any company resides in producing goods and services which will satisfy customers. The customer has therefore systematically become the center of all attention and in spite of attempts to draw up methods which can detect his latent needs (MOD2), research never strays from the objective of achieving consumer satisfaction. While this aim may be praiseworthy and provide economic security (we can scarcely imagine a consumer buying something he doesn’t like), the founding principles of the Theory of Inventive Problem Solving demonstrates that the evolution of technological systems is controlled by a set of objective laws defined in a broad spectrum of articles and works [5-6] . This sets the consumer and his desires in contradiction with the objective laws which control these evolutions. We then find it hard to imagine that if these two directions are not concordant, then one is moving in the right direction and the other in the wrong direction.

In his article on the evolution laws of technical systems [7] , G. Altshuller points out that the risk of breaking these laws (by analogy with civil law) may be sanctioned by the market of the future (just as a breach of the civil code can be sanctioned in court). But beyond formulating these laws, our article sets out to demonstrate that in opposition to the objective of designing the product (or system) in accordance with the consumer’s desire, there is another design path whose aim, at a very upstream phase of the project, is to reduce the prospective phantom of solution-seeking in accordance with these laws so as to reduce significantly the risks of serial “trials and errors”. We shall also demonstrate that, without upsetting the habits of the designer to any great extent, it is possible to increase the degree of ideality of the solutions found and to make them industrially viable while keeping constantly in line with the company’s capacity to implement them.

2. PRIORITY AIM: REDUCING THE SPHERE OF CONCEPT-SEEKING

2.1 Context

It is generally acknowledged that when an engineer is in charge of a project, his objective in the creation phase is to generate a maximum number of concepts in a minimum amount of time. This strategy often results in psychological inertia and stress related to respecting the schedule of the project. However, trying to design a product or service under the pressure of requirements dictated by the problem specifications is counter-productive for the engineer. Moreover, the specifications of the problem in hand may be considered as the outcome of technological solutions proposed in the past and new requirements dictated by the market and the influence of rival companies.

But what are the ideal conditions for improving a technical system (or a process currently under development) using known methods of optimization? What strategy should be adopted when the problem cannot be solved by conventional optimization procedures and a truly innovative solutions is needed? In other words, how can we optimize the idea-generating phase during the design process?

Most of these strategies can be sub-divided into two groups: Systematic tests and non-systematic tests.

These two categories are based on the following principle:

“HOW can the situation which poses a problem be solved?”.

Brainstorming is a typical example of the first group since it does not go beyond a thought process, which may well be governed by a certain number of rules, but whose efficiency depends on the skills of individual team members alone. The second groups include a large number of methods which are broadly used in research and development centers where the areas to be explored can be shared out among several project teams. Yet, while this strategy was successful during the twentieth century, it is proving to be costly today and inefficient in a number of cases, which means it no longer meets the requirements of the new rules governing our economy.

A new strategy must therefore include a set of characteristics:

* Guaranteeing an excellent level of reliability so that the design phases may be planned with accuracy;

* Offering a low utilization cost in order to minimize human involvement;

* Benefiting from a capacity to generate ideas systematically when these are lacking;

* Including an aptitude to turn around the psychological inertia of the experts in the field;

* Guaranteeing clarity and understanding of the solutions generated.

It is true that the theory of inventive problem-solving seems to include many of these features. Yet, just as with many other theories, mastering the theory still requires a certain amount of study and practice. And while there are many people today, who have mastered a number of tools and methods proposed by TRIZ, there is nonetheless an obvious gap in terms of the strategy of its overall application.

G. Altshuller demonstrated the need to reduce the sphere of research [8-9] , but this point has remained at the level of an informal acceptance among TRIZ experts.

2.2 Description of the approach reducing the sphere of research

Let us begin by drawing up a non-exhaustive list of the restrictions that the designer has to contend with during the problem-solving phase:

* Time limit;

* Prohibitive cost of the solutions (limited allocation of resources);

* Psychological inertia caused by the sometimes overspecialized skills in a specific domain;

* Lack of knowledge on a given topic (it is impossible to know everything).

It is obvious that if no time limit is set, any theory can come up with a solution to a problem, helped by chance, since trial and error tests can be continued indefinitely. And yet if, on the contrary, the designer only has a few seconds to solve a problem, even the most powerful computer will fail at the task. What TRIZ proposes to do is to set down the problems in the shape of an organizational contradiction initially and then to evolve methodically towards formulating a physical contradiction. Through an analogy with engineering problems, here is how our problem can be formulated: Problem definition: How can the solution-seeking sphere be reduced from among the infinite variations possible without using a trial-and-error type procedure? [10] Contradiction: It is necessary to differentiate precisely and systematically between possible and impossible concepts so as to uphold the following objectives:

– Impossibility of missing a good solution

– Need to rid oneself of psychological inertia But it is also necessary to exclude the systematic, precise aspect of research for the following reasons:

– Lower research costs

– Too little time to exploit potential leads (sometimes lack of knowledge).

2.3 Summary of the conventional methods used

Here are some methods [11] stemming from the TRIZ framework and which are traditionally used with the aim of solving a key contradiction during the design process:

* The why-why diagram. This is a stem and leaf diagram where the starting point consists in asking the question “Why is there a problem?”. The aim is to develop a diagram with a few principal and secondary branches. The project team continues the question process by repeating the question “why?” until the roots of the problem become apparent. The root cases are identified if the problem is repeated or appears in several branches in the diagram.

* The-cause-and-effect diagram. Also known as the Ishikawa or fishbone diagram, this is broadly used with the aim of collating and structuring the data linked with the causes of problems and making them converge towards the most probable root of the same problem.

* The Pareto chart. This is a bar graph which is used to prioritize causes (or observations) where the causes with the greatest weight in the problem at hand are located on the left of the diagram and then given in decreasing order of occurrence. Its principle is based on Pareto’s law which stipulates that only 20% of causes are implied in 80% of problems, whereas inversely, 80% of causes only generate 20% of the problem.

* The interrelations diagram. The purpose of this tool is to explore cause and effect relations on the basis of the results yielded and to identify the root causes The main causes (from 4 to 10) identified by the cause and effect diagram are represented in circles. The project team identifies the cause/influence relationship by analyzing each factor in turn. Starting with a factor chosen at random, the team is asked whether a causal relationship exists between this factor and the adjacent factors. The most significant relationships (shown on the graph in the form of arrows) are presented in bold type.

* Experience plan. The Experience Plan method aims to seek the best compromise solution between a set of parameters with multiple-level factors. The method integrates a statistical mathematical tool which takes into account the natural variability of the phenomenon and the following positive points can be noted in this approach:

o a significant drop in the number of trials to find the best compromise;

o the possibility of increasing the number of factors under study or their levels;

o taking into account any interactions between factors;

o simple modeling of the results;

o good level of accuracy in determining the results.

What do these methods have in common? They are all focused on the restrictions related to the situation at the outset without taking into account the objective rules which influence the logical evolution of the system under study. At this stage, we should recall the key points in the approach proposed by the theory of inventive problem solving:

* Technical systems evolve in accordance with certain rules (laws)

* These rules may be identified by observing the knowledge gained during the evolution of technical systems

* These rules may be used to innovate within a technical system with the aim of systematizing this evolution.

* It is possible to make the problem-solving process progress from the random to the systematic while keeping in line with these objective laws.

* An analysis of the initial situation of a problem which does not take into account the restrictions resulting from these rules of evolution, is destined to fail or depends solely on the chance factor [12] .

2.4 What does TRIZ offer?

The main difference between known methods for generating new ideas and TRIZ, is that TRIZ leads to a systematic analysis of the root of the problem on the basis of exhaustive knowledge of the rules governing the evolution of technical systems, scientific know-how (such as the laws of physics and chemistry) and the restrictions imposed by the specificity of the problem. Several levels of detail are brought into play in order to summarize the results of the model describing the problem (contradiction). This strategy, as opposed to generating a maximum number of ideas, aims to confine this number to those with the highest potential.

Each stage on the path separating the problem from its solution is examined by a contradiction model which is constantly challenged by the objective restrictions, thereby enabling the sphere of research to be narrowed at each step. Instead of collating a high number of concepts and sorting them afterwards, the optimum concept selection process is integrated in the approach to the analysis [13] .

At the outset, the analysis of the problem’s field of investigation is determined by the principal function of the technical system, the list of the main components of the system and the expected objective of the problem-solving process. A model, in the shape of a contradiction, is built in order to piece together a clear-cut answer to the question “Why do we have a problem?” or “What is keeping us from solving the problem?”.

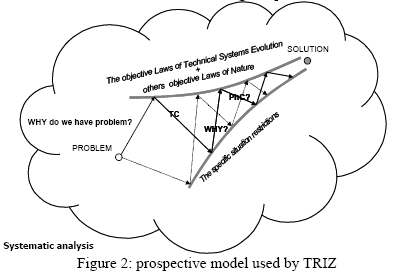

Traditionally, a technical contradiction describes the following situation ” we know in which direction we should go to find the expected result, but if our idea is implemented, then the system deteriorates”. This deterioration is only visible because a certain number of objective restrictions still remain hidden at this stage and probably a number of other restrictions linked with the situation have not been taken into account. In figure 2, this situation is represented by the two main arrows.

Only a limited number of elements stemming from the analysis of the situation at the outset are retained and analyzed when dealing with the problem. The designer nevertheless obtains clear directions from this type of analysis as to the typology of the additional information required to solve it. From here, an additional analysis of the problem model in terms of seeking the key resources for solving it, the expected Ideal Final Result and the physical contradiction, enables us to collect significant information on the objective and specific restrictions which make up the conflict (or problem). As to the results yielded by this type of analysis, a list of the properties of the interacting elements is built up following the pattern Element ? Parameters ? Target Values (EPV). At this juncture, only a limited number of concepts can meet the properties required in accordance with the restrictions analyzed beforehand. Furthermore, meeting this list of properties will lead to innovative and robust solutions.

The diagram given in figure 2 is, in fact, no more than a (simplified) representation of the key idea inherent in the formalism highlighted by G. Altshuller in ARIZ. [9, 12]

3. CASE STUDY

3.1 Introduction

In the automobile industry, well-being and safety are priority objectives and ventilation within the car must be optimized at all levels so as to increase the thermal comfort of the user. The current trend is to offer a concept of diffused ventilation integrated into the dashboard in addition to traditional ventilators. There is little prior experience in this field, but several studies in the research phase are being conducted by companies.

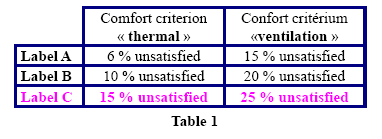

The aim of this project (conducted in partnership with the company Faurecia) is to set up a convergent design mode so as to produce a ventilation system diffusing air into the passenger compartment to improve the thermal comfort of passengers. The project is centered on the passenger compartment of the Peugeot 406 and the concept selected must meet the requirements of a label system (cf. table 1). The choice adopted is Label C, i.e. the new concept must satisfy 85% of passengers in terms of thermal comfort and 75% in terms of ventilation.

The correspondence between the parameters and values to be allocated is given in table 2.

Key stages to reformulation

Principal function of the system: To diffuse air stemming from an air-conditioning unit in the passenger compartment.

The Ideal Final result (IFR) : An ideal system of ventilation would be :

* small in size,

* light weight,

* made up of a minimum number of parts,

* sound proof,

* would diffuse heating or cooling air evenly inside the passenger compartment,

* adaptable to all car versions,

* with low loss of charges.

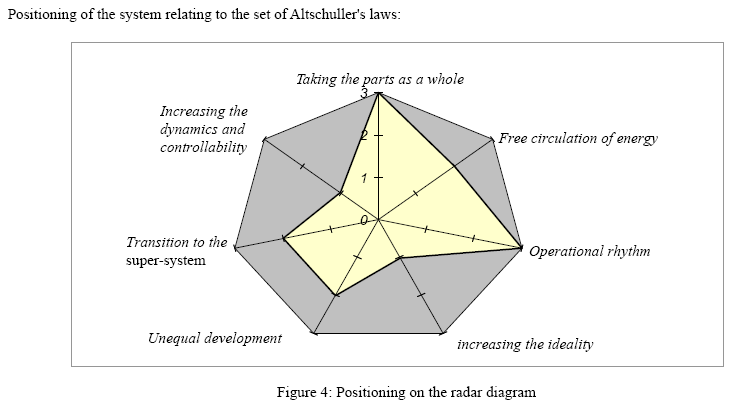

Positioning of the system in relation to the laws of evolution:

Generic morphology of the system and its principal components as defined by Law 1:

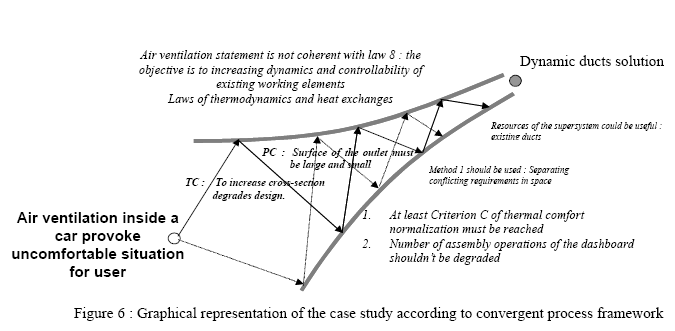

Statement of the problem using the formalism of contradictions:

Organizational contradiction: I would like to diffuse air in the passenger compartment of a car

Technical contradiction: When I increase the cross-section of the nozzle, the outlet speed is lower but detracts from the design

Physical contradiction: The surface are of the outlet must be both large to reduce the air outlet speed and small to limit bulkiness and not detract from the style.

3.3 Solving the physical contradiction

Concept N°5: dynamic de-icing duct

Principle: The de-icing duct operates by a translatory movement. It thus opens a new air outlet obstructed by the foam molding on the dashboard.

3.4 Construction of a viable industrial solution: Making the de-icing duct dynamic

A ventilation system diffusing air is put forward in figure 6 and offers a wide cross-section for the additional air outlet through the translation movement of the de-icing duct. This additional section is only activated when the duct is set in the high position so as to preserve all the features of current deicing systems. The translatory movement is actuated by connecting rods which are driven by a rotational movement through rods linked to the Man/Machine Interface on the dashboard with pins which slide in the grooves of the duct. These connecting rods are clipped onto supports which themselves are riveted onto the de-icing conduits.

The technical considerations are mainly related to guiding the sliding link. To counter the buttressing effect, the driving force of the connecting rods is directed in such a way so as to have a unilateral contact between the duct and the frame. With this layout, whereby all the forces are applied to the duct, the efficiency of the slide is 0.86 and the actuation force is 12 N. For this solution not to be penalized, the sequence of assembly operations must be the same as for the ducts currently used, i.e. the dashboard should be turned around any more than at present.

The number of operations is higher than for a conventional duct, but the number of times the dashboard is turned around remains unchanged. Furthermore, some operations (clipping on the connecting rods, riveting the supports) can be carried out at the same time as the welding operation for the de-icing ducts.

A graphical representation of the design process evolution used within the framework of TRIZ is given figure 6, and clearly state about the link between the convergent process approach (presented in the first part of this paper) and the results of the main steps of this case study. We should also note that in opposition to a large number of ideas generated with several interpretations of various principle (which has never been a mean in TRIZ philosophy) the convergent process remains in concordance with one of the main objective of industry needs : reducing R&D costs while improving quality and efficiency of an innovative solution.

4. Challenges/prospects

This case has demonstrated, as many other experiments have also done, that the impact of the practical application of concepts reducing the sphere of solution-seeking by using TRIZ has a positive effect on the inventiveness of the proposals put forward by project teams. There is considerable improvement in terms of the cost aspect, which is at the heart of all industrial decision-makers’ concerns, and we also observe that corporate management policies towards innovation must undergo some change.

Our approach gives rise to new prospects on many levels. First of all, it is necessary to challenge the whole architecture of the design process, since current work is based on grounds which claim that product evolutions cannot be controlled and that because of this, prospects tend to move in directions which rely on the skills of the project members alone (or the company’s know-how). This essential adaptation of the objectives of the design process must mainly be carried out during the upstream phases and the stages where the problem is formalized, because it is essential to reduce the sphere of solution-seeking and therefore the potential investment required. The presented approach is not an extended version of

TRIZ but our contribution is oriented toward clarification of TRIZ uses. It lies in the fact that many restricted or inadequate uses of TRIZ have been made lately, since incomplete vision of TRIZ’s basics create fuzziness or disappointments in the mastering of the way a TRIZ project can be conducted so as in the quality of the obtained results. Yet prior to this, it is up to researchers inspired by the theories developed by Altshuller, to solve the problem posed by transferring TRIZ in view of how complex it is to come to terms with it [14] . We should perhaps note in passing that attempts to simplify it (USIT, ASIT [15] , ITRIZ and others) or attempts to produce software (TechOptimizer, Innovation Workbench and others) only offer a degree of success limited to the originality of the theoretical bases of TRIZ, without fully exploiting its entire scope but nevertheless proposes a quick answer for those who did not have time to dedicate to build TRIZ competences but still want to benefit from it. Our research work is moving in this direction: the aim is to gain in-depth knowledge and fully grasp the modes of transferring TRIZ so as to foster the relevance of its integration in the design processes of companies, while taking into account all fields related to engineering involved in everyday realities of the industrial world and which can influence the overall efficiency of the design process.

ACKNOWLEDGMENTS

Many thanks to Nokolai Khomenko for useful discussions on the subject.

REFERENCES

[1] Malmqvist J., Axelsson R., Johansson M., “A comparative analysis of the theory of inventive problem solving and the systematic approach of Pahl and Beitzâ€, ASME Design Engineering Technical Conference, August 18-22, Irvine, California, 1996.

[2] Nordlund M., “An Information Framework for Engineering Design based on Axiomatic Designâ€, Doctoral Thesis, Department of Manufacturing Systems, The Royal Institute of Technology (KTH), Stockholm, Sweden, 1996. ISRN KTH/TSM/R-96/11-SE

[3] Schulz A., Clausing D., Negele H., Fricke E., “Shifting the view in systems development – Technology Development at the fuzzy front end as a key to successâ€, Proceedings of 1999 ASME DETC, 11th International Conference on Design Theory and Methodology, Las Vegas, September 12th –15th, 1999.

[4] Verduyn D. & A. Wu, “Integration of QFD, TRIZ, & Robust Design: Overview & Mountain Bike Case Studyâ€, Proceedings ASI Total Product Development Symposium, November 1-3, Dearborn, MI, USA, 1995.

[5] D. Cavallucci, 2001, “Integrating Altshuller’s Development Laws for Technical Systems into the Design Process.†Annals of the CIRP 50(1): 115-120.

[6] Salamatov Yu. P., 1991, “A System of Laws of Engineering Evolution”, in Chance for Adventure, A.B. Selutsky ed., Petrozavodsk, Russia.

[7] G.S. Altshuller: 1977, Laws of technical systems evolution (Manuscript).

[8] G.S. Altshuller: 1999, THE INNOVATION ALGORITHM: TRIZ, systematic innovation, and technical creativity. Translated by Lev Shulyak and Steven Rodman Worchester, Massachusetts: Technical Innovation Center. ISBN 0964074044 (origin: G.S. Altshuller: 1969, 1973. ALGORITHM OF INVENTION, Moscowskiy Rabochy, Moscow)

[9] G.S. Altshuller: 1986. The history of ARIZ development. (Manuscript)

[10] N.N. Khomenko: 1997-2001. Materials for seminars: OTSM-TRIZ: Main technologies of problem solving, “Jonathan Livingston†Project. (Manuscript)

[11] G.E. Dieter: 2000 ENGINEERING DESIGN: a materials and processing approach. 3rd ed., McGraw-Hill International edition. ISBN 0-07-366136-8

[12] G.S. Altshuller: 1984, CREATIVITY AS AN EXACT SCIENCE: The Theory of the Solution of Inventive Problems. Translated by Anthony Williams. Gordon and Breach Science Publishers. ISBN 0-677-21230-5 (origin: G.S. Altshuller: 1979. CREATIVITY AS AN EXACT SCIENCE. Sovietskoe radio, Moscow.)

[13] D.A. Kucharavy: 1998-2001. Materials for seminars: TRIZ Techniques, OTSM-TRIZ Technologies Center (Minsk, Belarus). (Manuscript)

[14] Cavallucci, D., 1999, “Contribution to new mechanical system design using methodological integration“, Doctoral Thesis, Université Louis Pasteur.

[15] Horowitz R., Maimon O., “Creative Design Methodology and the Sit Method”, Proceedings of DETC ’97: 1997 ASME Design Engineering Technical Conference, Sacramento, 1997.