Computer-Aided Design: Forecasted Evolution

Editor | On 05, May 2003

By: V. Abate (1), G. Cascini (2)

(1) Invention Machine Italy

Direzione Tecnica

e-mail: vabate@invention-machine.com

(2)Università degli Studi di Firenze

Facoltà di Ingegneria, Dip. di Meccanica e Tecnologie Ind.li

e-mail: gaetano.cascini@unifi.it

ABSTRACT

In this paper CAD systems are analyzed from the perspective of conceptual design, highlighting their limitations and sore points. A set of solutions to improve the suitability of these tools for the earlier phases of products development cycle is proposed on the basis of TRIZ inventive principles. Moreover, a long term scenario is forecasted according to the typical patterns of technical systems evolution.

1. Introduction

The product cycle is drastically changed since CAE applications for virtual prototyping have been introduced into the market and their cost reached a level accessible even for SMEs: any kind of simulation can be performed with manageable efforts by designers in the early stages of product development and the work can be approached in a cooperative environment satisfying the time-to-market constrains. Nevertheless, such an advantageous situation has a dramatic drawback: several solutions are submitted to computational tests without any preliminary check of their functional efficiency; basically the conceptual design phase has been reduced in favor of virtual prototypes analyses.

As a consequence the CAD systems evolution has been focused on the satisfaction of detail design requirements: management of assemblies with huge amount of parts; complex shapes modeling; integration with CAE applications; specific tools for niche sectors (i.e. metal sheet, piping etc.); customizability through Application Protocols Interfaces or specific languages etc. In facts, nowadays entry-level mechanical CAD functionalities are not so far from the features of top-level systems.

The result is that especially young engineers spend little time analyzing the problem and developing ideas, while much more time is dedicated to the implementation of alternative solutions in the CAD environment. As a consequence, previous works borrows the product architecture and very often the shape of a part is constrained by user modeling skill: both these limitations added to psychological inertia dramatically reduce the innovation capabilities of the designer.

Nevertheless, even an “old style†designer, who usually starts working with a blank paper page and a pencil, could benefit from the availability of a CAD system, as easy to use as a paper sheet, but supporting him in terms of knowledge and 3D geometry management.

Nowadays the draftsman faces a paradox: ease of usage produces lack of knowledge. Approaching the analysis of CAD systems evolution by means of the ultimate techniques of TRIZ theory is an effective way to forecast the next step of design software tools in order to raise the speed toward the future. Paths of evolution can be used to define medium/long term scenarios, by combining evolution steps and pattern jumps (see for example by Domb 2000, Ikovenko 1999, Mann 1999, Sawaguchi 2001, Zlotin and Zusman 2001).

Furthermore, TRIZ theory frame can be used to organize forecasted utopias about CAD systems and rank the points of intervention in their evolution. In this paper the major limitations of actual mechanical CAD software are analyzed focusing on the conceptual design phase requirements; some suggestions to overcome the identified contradictions are proposed on the basis of TRIZ trends of evolution.

2. Background of CAD systems

The first 3D CAD systems appeared in the early 1970’s. At the beginning the geometry representation used to be a “trivial†wire frame, i.e. a simple skeletal model; Hidden Line Removal algorithms gave the immediate following step. While 2D CAD were used just for drafting purposes as electronic drawing machines, the availability of three dimensional models let the user “walk around” an object to get a feeling of its solidarity and point at a feature to modify it directly.

Then the canvas was added to the frame tent, colors and textures could be added to the surface, but all objects were hollow (3D surfaces).

The relevant step toward 3D solid modeling was given by CSG representation, that is using solid primitives combined by means of union, intersection and subtraction Boolean operators. The model is stored in a tree with all the information about primitives and the way they are combined. The ability to edit the tree, i.e. the transition to parametric models, is a fundamental step to support the typical iterative process of design activity.

The introduction of Boundary representation (B-rep), consisting in a description of solid geometry by means of its skin, mathematically expressed through NURBS, allowed the definition of complex shapes even with limited computation efforts. From the user interface point of view, feature-based modeling changed the approach to CAD models definition, from geometry to technology-centric: geometric entities are now grouped according to the technological meaning of the shape element. Actually solid modelers still are parametric and feature based: very limited facilities are offered for conceptual design and shape definition.

While industrial designers work with surface modelers to conceive and generate freeform surfaces, no tools are available for mechanical assemblies early design. The trend of CAD systems in the last few years involves several tasks, but none of them toward conceptual design support:

* Augmenting free-form modeling features is intended as the capability to represent more and more complex shapes, but the user still must have a clear idea of the geometry to be generated;

* Standard parts libraries are very useful to speed up detailed design tasks, but they enhance psychological inertia during concepts generation phases;

* Virtual prototyping tools integration, as described in the previous section, are creativity killers in the early phases of product development;

* Design intent representation and knowledge based systems might improve effectively CAD systems capabilities, but the results obtained so far are still too poor to effectively support designers.

The aim of this work is to apply modern theories for technological forecasting to CAD systems in order to identify the most plausible scenarios for Computer-Aided Conceptual Design tools.

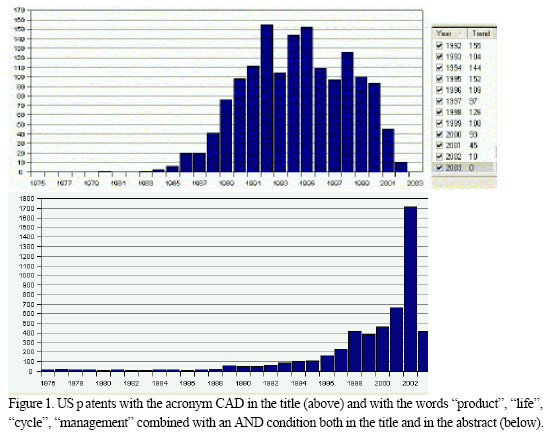

According to this purpose, it is useful to get a look to the US patents registered with the CAD acronym in the title (figure 1): it is clear that such a system has reached its maturity and the transition to a new S-curve is supposed to succeed. As described more deeply in section 4, an already identified evolution is the transition to the product life cycle management (PLM) tools supersystem, as demonstrated by the corresponding patents flow. This extremely superficial analysis is nevertheless sufficient as an introduction for the purposes of this paper; the authors will discuss a more detailed patent search and comparison in the future.

3. CAD analysis from a conceptual design point of view

Introducing new solutions in an existing product is a hard task for designers who start working directly in the CAD environment: in facts, several limitations are imposed to the human creativity since the existing interface is tuned to the detail design phase. Feature-based modeling tries to take into account technological matters of parts geometry, but no relevance is given to the process of shape conception. First of all, the designer has to face product design distinguishing between improving parts shape design and assembly design as they were two separate entities, since parts and assemblies are managed in two different environments. In facts, from the conceptual design point of view, the top down modeling approach is not sufficient to overcome this dramatic constrain; besides, during the first stages of product definition designers don’t know how many parts are going to be defined and the unique goal should be accomplishing functions.

The existence of a double modeling environment is due to ease of modeling requirements; moreover, it allows the management of complex mechanical system through a hierarchy of assemblies, sub-assemblies, parts and features. Nevertheless this solution is admittable only when the system to be embodied is already, even if roughly, defined. Moreover, it enhances the psychological inertia of technicians and their reluctance to changes since, for example, a long series of operations must be performed to segment a component into different parts easier to manufacture.

From the parts shape point of view, actual CAD system are provided with several separated modeling functions, easy to use and easy to implement, requiring affordable flexible, apart for dimensional parameters changes.

In order to perform a systematic and comprehensive analysis of mechanical CAD systems it is useful to combine the problem definition tools by Ideation (Innovation WorkBench) and Invention Machine (Tech Optimizer): the former allows the definition of a model of the actual situation in terms of cause-effect relationships, to be automatically translated into basic directions of innovation; the latter has been used to build a functional model of CAD modules and features in order to rank their efficiency according to the Value Analysis principles.

The diagram developed by means of IWB depicting the aforementioned situation is shown in figure 2.

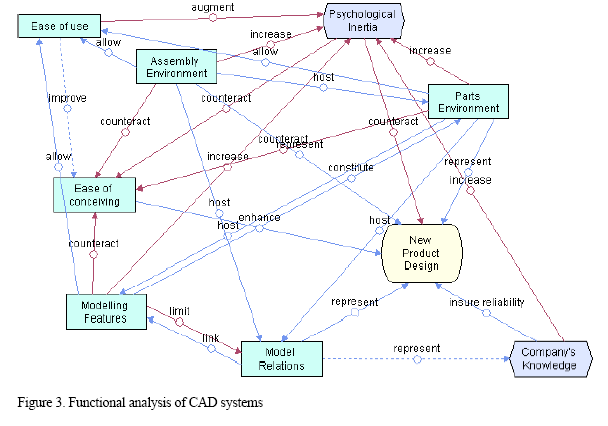

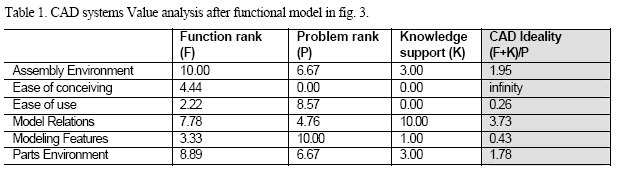

In order to identify the limits of actual CAD systems and the trends to be followed with the goal of improving the innovation capabilities of designers and technicians a functional analysis of CAD modules and features has been performed at an almost abstract level (figure 3).

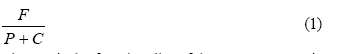

According to the principles of Value Analysis the efficiency of the system components has been evaluated taking into account functionalities, benefits, problems and costs. The value of a component is usually calculated as the following ratio:

where F is the functionality of the component, P is a measure of the problems it carries on and C is its cost; these parameters are of course normalized in order to be comparable.

The functionality is evaluated by counting the number of useful functions performed by a component, weighted by 1/n, where n is the “minimum distance†of such an action from the product of the functional diagram (i.e. the object of the main function of the system). The parameter expressing the problems related to a component is evaluated as the sum of the harmfulness and/or the inadequacy of its functions [Arel et al. 2002] .

In this work, the value of CAD modules and features has been expressed as:

The parameter C (costs) has been omitted since it is no relevant in such a context; besides it has been added a parameter K, representing the Knowledge support of a component to the design of innovative products. In Table 1 all the aforementioned parameters are summarized.

Ease of use has not surprisingly a very low value: it should be taken into account that this analysis has been focused on conceptual design. Further comments about these results will be presented in section 4.2.

4. CAD evolution

The former analysis can be systematically translated, according to the ARIZ algorithm, into a set of eighteen directions of innovation to be examined in order to identify the next steps in CAD evolution; two of them, besides being very basic and important targets, are out of the scopes of the present discussion:

1. Find an alternative way to obtain the “product innovation by CAD†that does not require “improving shape design†and “improving assembly design†and is not influenced by “part/assembly separate environment†and “psychological inertiaâ€.

2. Try to resolve the following contradiction: the useful factor “ease of modelling†should be in place in order to fulfill useful purpose and should not exist in order to avoid “part/assembly separate environmentâ€. Besides, most of them hint useful considerations to be futher investigated:

3. Find a way to eliminate the “part/assembly separate environment†in order to avoid “psychological inertiaâ€, under the conditions of the “ease of modelingâ€; then think how to provide “complex systems managementâ€.

4. Try to resolve the following contradiction: The harmful factor “part/assembly separate environment†should not exist in order to avoid “psychological inertia†and avoid hindering “product innovation by CAD†and “improving assembly designâ€, and should be in place in order to provide “complex systems managementâ€.

5. Find an alternative way to obtain “ease of modeling†that does not requires “part/assembly separate environmentâ€.

6. Find a way to eliminate, reduce, or prevent “psychological inertia†under the conditions of “part/assembly separate environment†and “company’s experienceâ€

7. Find an alternative way to preserve “company’s experience†that does not cause “psychological inertiaâ€.

8. Try to resolve the following contradiction: The useful factor “company’s experience†should be in place in order to fulfill useful purpose and should not exist in order to avoid “psychological inertiaâ€.

9. Find a way to eliminate “non flexible part geometry†under the conditions of “separated modeling functionsâ€.

10. Find an alternative way to “improve shape design†that enhances “product innovation by CAD†and is not influenced by “non flexible part geometryâ€.

11. Find a way to eliminate “separated modeling functions†in order to avoid “non flexible part geometryâ€, then think how to provide “ease of use†and “easy implementationâ€.

12. Try to resolve the following contradiction: The harmful factor “separated modeling functions†should not exist in order to avoid “non flexible part geometryâ€, and should be in place in order to enhance “ease of use†and “ease of implementationâ€.

13. Find an alternative way to obtain the “ease of use†that does not require “separated modeling functionsâ€.

14. Consider transitioning to the next generation of the system that will provide “ease of use†in a more effective way and/or will be free of existing problems.

15. Find an alternative way to obtain the “ease of implementation†that does not require “separated modeling functionsâ€.

16. Find an alternative way to “improve assembly design†that provides “product innovation by CAD†and is not influenced by “part/assembly separate environmentâ€.

17. Find an alternative way to provide “complex systems management†that does not require “part/assembly separate environmentâ€.

18. Consider transitioning to the next generation of the system that will provide “complex systems management†in a more effective way and/or will be free of existing problems.

4.1 Next future improvements

It is not possible to describe with the maximum detail all the suggestions provided by TRIZ tools for each specific direction of investigation; therefore just the strongest generated ideas will be mentioned together with the underlying inventive principle.

4.1.1 Shape modification

The problem 9 of the above list suggests eliminating the harmful results produced by non-flexible geometry. The same direction is pointed by problem 11, which can be translated into “isolating the system or its part from the harmful effect of several separated modeling functionsâ€. According to these purposes, the introduction of shape modification features, as a complement of the traditional “building†features, is a first step toward a modeling environment more suitable for geometry preliminary definition. These new features, analogous to those available in surface modelers, should allow the modification of a model by means of a sort of mechanical action like bending, twisting, squeezing etc. In facts, this kind of interface would be closer to the way of reasoning when the final geometry of a part is still vague (i.e. as the designer had a clay model in his hands).

At the end of such a design session, it would be useful a simplification of the modeling tree by means of features identification algorithms, similar to those proposed in Reverse Engineering tasks; compared with the typical problems that arise when feature identification must be performed on a cloud of points, a comprehensive set of information both about geometry and topology of the model is available, therefore the task should be easier and much more reliable.

Moreover, the contradiction highlighted by problem 12, can be overcome on the basis of the dynamization principle: instead of working with NURBS, whose deformation could be hard to implement and resources consuming, it is suggested the transition to a meshed model, even with linear elements, but still preserving its topological content. From the design point of view it is necessary the capability to introduce new relations to vertices, edges, faces (for example, constraining a set of edges to lay on a circle). Problem 14 suggests improving the ideality of the system in terms of ease of use: during the shape definition phase it is not so easy to build loft or sweep features due to the lack of reference points; moreover, sometimes it happens that such a complex shape is not necessary. For example, actually if a part has been modeled as a simple extrusion, it is not possible to convert it in a sweep and a complete reconstruction of the model should be performed. It would be useful the transition from a simple to a more complex shape by adding new intermediary sections (i.e. extrusion to loft conversion), or extrusion paths (extrusion/revolution to sweep conversion).

4.1.2 Knowledge integration and TRIZ features

Starting from problem 7, TRIZ operators suggest synthesizing a new system capable of providing the company’s experience. Knowledge Based systems and KAD tools approached such a task [see Abate et al. 2001, Cascini et al. 2001] . A comprehensive discussion about the opportunities and the limits of these systems is out of the scope of this work.

Nevertheless, it is worth to notice that, according to contradiction 8, a separation in time should be applied: the company’s knowledge should be neglected in the preliminary sessions of conceptual design and should be formalized in order to be used as an automatic check during feasibility analysis.

By analyzing together problems 7 and 9, an innovative way of storing knowledge into CAD system can be identified: according to TRIZ suggestions, problem 7 could be solved by using the integration principle, while problem 9 invites counteracting the harmful effect of non flexible geometry, for example by means of the separation principle. Since actual CAD systems do not allow an easy and quick modification of a shape, therefore enhancing psychological inertia, it would be useful the availability of a system capable of generating automatically alternative shapes as modifications of a given starting geometry. Such modifications should not be random, but knowledge driven. A powerful and general knowledge base is constituted by TRIZ inventive principles that work as solution triggers. As discussed in [Mann 2002] , many problem solvers think that there is a considerable gap between TRIZ generic solutions and the specific solution to the given problem and there is no way to define a general map from the abstract to the detail level. The authors subscribe this point of view, nevertheless in specific contexts such a map can be formalized; in the case of CAD modeling features it is not so hard to conceive how to modify a geometry according to TRIZ principles like “segmentationâ€, “dynamizationâ€, “merging†etc. Hence, a set of “TRIZ features†could be defined so that the CAD system itself supplies to the designer a set of alternative modifications of the geometry, defined automatically on the base of the selected principle. These proposals should still be considered as solution trigger, even if at a much more detailed level; the designer inspired by these suggestions still has the role of selecting the most suitable solution and implementing it properly. The authors have already tested some basic TRIZ features and an exemplary implementation is going to be presented in the next future.

Another way to store knowledge and make it reusable is improving the useful factor company’s knowledge: recording CAD models development history is actually possible thanks to the increased storage capabilities of computers. Such a database of geometry evolutions should be processed and synthesized just like Altshuller did with patents; a set of modeling trends could be extracted to improve the TRIZ feature knowledge base.

4.1.3 CAD/CAE integration

A typical pattern of evolution of technical systems consists in combining two or more different systems into an integrated supersystem. The integration of CAE tools inside the CAD environment is an already approached task. Major advantages can be achieved by completing such an integration: actually the data exchange is unidirectional from CAD to CAE, even in most of FEM shape optimization tools, while the inverse path would bring great benefits to design, both in terms of quality and speed.

4.1.4 New I/O devices

A solution to problem 14 is suggested in terms of increasing the controllability of the existing system that provides ease of use. Even this path of evolution has already been approached by several researchers by studying how to integrate 3D input devices to simplify the definition of complex shapes

4.1.5 CAD storming

The contradiction expressed by problem 8 is usually overcome by techniques focused on psychological barriers, like brainstorming. Is it possible to experience CAD storming? CAD storming means working together on a same model with the ability of applying deep changes to the geometry in absolute freedom. Such a cooperative work is mainly limited by the slowness of modeling activity, that counteracts brain-storming agility. Since changing easily and quickly the model geometry is still not possible a “partial action†is proposed: by means of a common speech recognition module, the comments of the design team could be automatically translated into raster images to be linked to the 3D model in order to store in a more effective way the proposed solutions to be evaluated.

4.1.6 Relations model

Contradictions like the one expressed by problem 4 can be solved by means of the separations principles, and most of all separation in time. During the conceptual design phase, the distinction between assembly and part environment is unuseful, while it is more important the possibility to define any kind of relations among the geometric entities, as well as splitting a given geometry into several parts or joining many of them into an unique component, so that the designer can focus his activity on the definition of functional surfaces.

In other words, the designer should be able to start his work by defining reference and functional surfaces, without taking into account if they belong to a single part or to several. Then such surfaces should be linked both with solid features and mono/bidimensional reference entities. This environment should allow also the definition of any kind of links between the geometric entities, as well as properties and constrains: working volume, mass properties, speeds, interactions etc.

4.2 Next generation of design tools

CAD systems aid designers making use of the resources provided by computer technology. Their evolution has followed the typical trend of technical systems, i.e. specialization and performances increase of characteristic features. A complete system is usually constituted by four components: Working Tool, Transmission, Energy Source, and Control. During the first stages of CAD evolution, major efforts have been dedicated to the Working Tool, i.e. the geometric kernel, Part and Assembly environments; then, the information flow (Transmission) has been improved in terms of Modeling Features capabilities, making CAD systems closer to the “Energy Source†(Knowledge). As described above this path is still not completed and further developments should follow.

Promising results are expected from the, at least partial, “encapsulation†of the Energy Source. Nevertheless, apart from some ambitious researches, actually CAD systems neither create knowledge nor allow the generation of information within the system. Therefore, it is expected a transition toward the integration of a module capable to support knowledge creation. The ideal final result of such a trend is a self-operating design system, while the user should perform just “control†tasks, by selecting and not defining the most suitable solution.

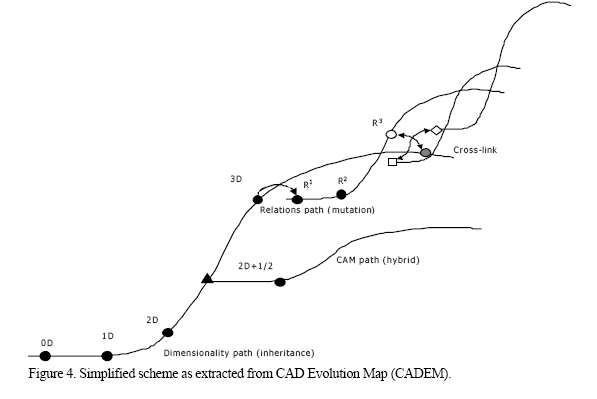

A simplified scheme representing CAD evolution is shown in figure 4, where the main steps described in section 2 are depicted, as well as a hypothetical evolution. Geometrycentered systems have followed the dimensionality change evolution; such a path can still be followed for specific applications, by introducing time as the fourth dimension: multibody software and CAM systems are an already existing example of this evolution. A long-term perspective could re-open the dimensionality trend when applications of quantum computing will be available.

The introduction of feature-based modeling is the sign of the transition to a new path. The key element of this transition is the introduction of implicit relations between the geometric entities, while changing dimensionality has reached its highest level. The “relations†S-curve, just approached, allows the identification of the next steps: first relations have linked geometric entities with the introduction of the modeling features. Then relations have been defined between features (associativity). Hence the trend of relations is toward the link of entities closer to the Energy Source as discussed above. It is possible to forecast that in the future relations will be defined between something even closer to knowledge, i.e. relations between relations and links of geometry to concepts. Such a scenario is compatible with the conceptual solution proposed in section 4.1.6.

An alternative scenario suggests a differentiation at a microlevel, by introducing a new system of many “atomic†features, driven by simplified rules. This scenario is still based on the hypothesis that the designer will assume the role of a project supervisor (control): he will work by defining relations, requirements and constrains rather then modeling the geometry of the designed system.

In such a context, the definition of a product geometry, as well as any shape changes, will be driven by conceptual and functional inputs rather then geometric or technological ones as actually happens by means of rules capable of mapping semantic requirements into geometric entities; in other words feature-based modeling will be followed by semantic modeling. An exemplary proposal that points to this trend has been proposed by Mandorli et al. (1997): the traditional feature definition is extended in order to include the set of rules that allows for feature instances to control the consistency of their shape in respect to functionality associated. In any case it appears that the evolution of computer-aided design systems will be based on relations and rules. As an immediate consequence, actual efforts dedicated to modeling feature improvements are not so useful, since geometry and features must be considered as outputs and not inputs. The Value Analysis presented in section 3 supports such a statement too.

5. Conclusions

The analysis of CAD systems from the conceptual design point of view has shown an almost total inadequacy of existing tools. After identifying the sore points of the system a double step evolution has been proposed on the basis of TRIZ theory. The paper presents first a set of solutions to improve the suitability of computer-aided design tools for the earlier phases of products development cycle. Then, a long-term scenario has been forecasted according to the typical patterns of technical systems evolution. Such a scenario involves the disappearance of CAD systems as actually conceived, while it is plausible a transition of computer-aided design tools to an higher level in the product cycle, i.e. a transition to supersystem as typically performed by technical systems at the end of an evolution path.

The authors are going to discuss the details of the proposals made in this paper, as well as some exemplary implementations, in a series of articles for The TRIZ Journal in the next future.

Reference

Abate V., Cascini G., Rissone P., Extracting Technical Knowledge for the Computer-

Aided Design of Adhesively-Bonded Joints, 7th International Conference on Production

Engineering, Design and Control (ASME), Alexandria, Egypt, 13 – 15 February 2001.

AuEna T. Arel, Mikhail Verbitsky, Igor Devoino, and Sergei Ikovenko,

TechOptimizerâ„¢ Fundamentals, Invention Machine Educational Services, 2002

Cascini G., Corsi C., Rissone P., From CAD to KAD: a design tool for adhesively – bonded joints with a dynamic knowledge base, 12th ADM International Conference on

Design Tools and Methods in Industrial Engineering, Rimini, Italy, 5-7.9.2001.

Mandorli F. Cugini U., Otto H.E., Kimura F., Modeling with self validation features,

Proceedings of the 1997 4th Symposium on Solid Modeling and Applications, Atlanta, USA, 1997.

Domb E., Strategic TRIZ and Tactical TRIZ: Using the Technology Evolution Tools,

The TRIZ Journal, January, 2000.

Ikovenko S, Speeding the Innovation Process: How to Improve the Performance of

Engineering Systems, NASA Tech Briefs Short Course, Photonics EAST, 19-22

September 1999.

Mann D., Using S-Curves and Trends of Evolution in R&D Strategy Planning, The

TRIZ Journal, July, 1999.

Mann D., Hands-On Systematic Innovation, Creax, 2002.

Sawaguchi M., Study of Effective New Product Development Activities through

Combinatio n of Patterns of Evolution of Technological Systems and VE, Proceedings of

TRIZCON2001, The Altshuller Institute, March, 2001.

Zlotin B., Zusman A., Directed Evolution Philosphy, Theory and Practice, Ideation

International Inc., 2001.