Case Study - Applying the TRIZ Methodology to Machine Maintenance

Editor | On 22, Aug 2003

By: John Cooney, Darrell Mann

John Cooney

Academic Researcher

School of Business and Government

National University of Ireland, Cork

j.cooney@ucc.ie

Darrell Mann

Director

CREAX nv, Ieper, Belgium

darrell.mann@creax.com

Barry Winkless

Creax, Ireland

bwinkless@eircom.net

1 Introduction

For the majority of companies, maintenance represents a very significant function within the production system. The increase in automation and the complexity of the control systems involved have made the reliability of equipment even more important (Cooney et al., 1999). Maintenance is performed to eliminate system failure traps and hazards in order to ensure that equipment continues to work within design tolerances and specifications (Cooney, 2001). This ensures that the defined functions and standards of operations of the plant and equipment are capable of being performed for the required period (Ashayeri et al, 1996; Lauer and Straub,1993).

Maintenance systems are dynamic because they are influenced by other factors within the system, for example, intuition, judgements and budgets. The dynamics of both the plant, equipment and the inherent characteristics of the materials used in production and maintenance. All of these factors have a direct impact on the behaviour of the maintenance system over time and on its underlying structure, strategies, processes and decision rules.

Hoffman (1991), suggests that maintenance is, first and foremost, the “difficult error localisation at numerous interfaces among products, systems and technical processesâ€. The task of error localisation must be now performed in a world of ever increasing technological sophistication. This has resulted in the maintenance function and its management becoming more complex. Consequently, there is a greater dependence on enabling technologies and methodologies to monitor and diagnose the causes of system failures traps and hazards and rectify the root cause (Cooney, 2001). A maintenance failure can be seen as the inability to produce work in the appropriate manner. Thus, equipment that deteriorates and consequently produces work of inferior quality or at a high cost is said to fail. Therefore, when a system fails, maintenance must be centred, firstly, on as possible (Ayerbe, 1995).

This maintenance case study applies the TRIZ methodology to assist solve a maintenance problem for a yoghurt drinks production system. The focus is placed on identifying the cause for bottles being damaged at the bottle un-scrambling machine. This is important since any damaged bottles that are allowed to enter the production system are highly likely to cause further system failures later in the process. Function analysis models are developed for three “time scenarios†concerning the un-scrambler machine. The original problem definition which was defined as “uncapped bottles†has being more clearly identified and redefined as “defective bottlesâ€. The redefined problem definition is mapped on to the new contradiction matrix (Mann et al, 2003) and suggested solution are developed based on the 40 inventive principles.

2 Yoghurt Drinks Production System

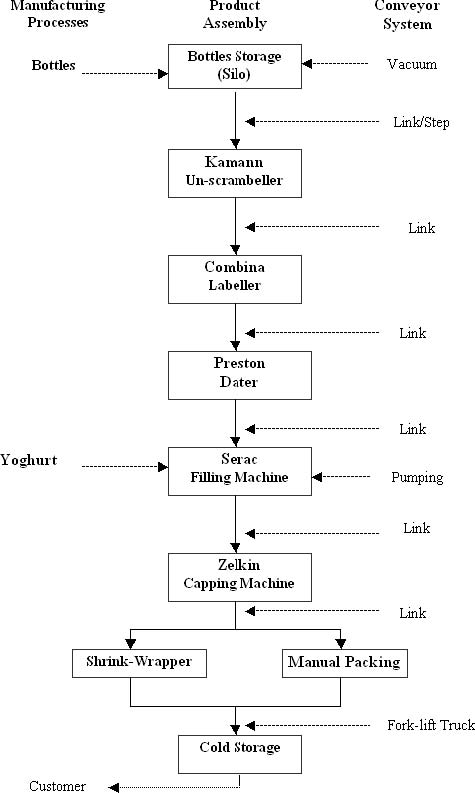

The yoghurt drinks production system (Figure 1.1) consists of the following equipment: Beckumbottle blowing moulding machine; Kamann-bottle unscrambler machine; Combina-labeler; Prestondater; Serac-filling machine; Zalkin-bottle capping machine; Shrink wrapper and a conveyor system.

Figure 1.1 Yoghurt Drinks Production System

3 Production System Processes

The flow diagram (Figure 1.2) illustrates the yoghurt drinks production system processes. The production of the final product involves two primary manufacturing processes and nine assembly process.

3.1 Manufacturing Processes

The manufacturing processes involves:

1. Blow moulding 200ml, 400ml and 750ml bottles.

2. The “yoghurt drink†manufacturing processes.

3.2 Assembly Processes

The assembly processes involves:

1. The moulded bottles are transferred by vacuum suction to a bottle storage tank (silo). The silo has the capacity to store one hundred and eighty thousand, 200ml bottles.

2. The bottles are released by a pusher from the base of the silo on to a link-conveyor that feeds the buffer storage tank.

3. The step conveyor feeds the bottles into the bottle-unscrambler machine which supplies the bottles in the correct orientation on to the link-conveyor system.

4. A link-conveyor feeds the bottles at an average rate of one hundred and twenty bottles per minute to the labelling machine where the appropriate product label is secured to the bottles.

5. The labels are then stamped with the “sell by†date.

6. The labelled and date stamped bottles are transferred by the conveyor to the Serac filling machine where the product is filled into the bottles through eight filling heads.

7. The filled bottles are transferred to the Zelkin capping machine to secure the product in their bottles. The bottle caps are fed from the caps silo to the capping heads through a gravity chute.

8. The conveyor transfers the secured bottled product to the packing area where it is either shrinkwrapped or manually packed into outer boxes for stacking on pallets.

9. The stacked pallets are transferred by fork-lift-truck to the cold store for distribution.

Figure 1.2 Process Flow Diagram:- Yoghurt Drinks Production System

4 Data and Information Analysis

The maintenance log sheets for a nine month period were examined and analysed to establish both the level of maintenance performed and maintenance times for the system. A sample of Operator Downtime Reports (ODR’s) were chosen for examination and analysis to establish the downtime for the yoghurt drink production system.

4.1 Analysis -Maintenance Log Sheets

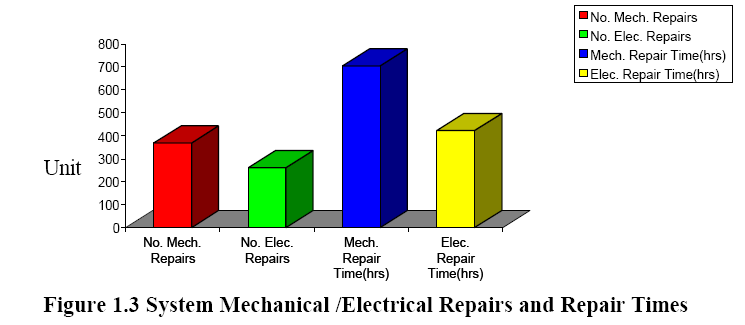

Figure 1.3 shows the system’s mechanical and electrical repairs and repair times for the nine month period. The production system required a greater number of mechanical repairs than electrical repairs. There were 368 mechanical repairs and 261 electrical repairs. The total repair times for the period were 704 hrs. for mechanical and 423 hrs. for electrical maintenance.

Figure 1.3 System Mechanical /Electrical Repairs and Repair Times

Mechanical maintenance of the system accounts for 58% of total system repairs and 62% of the total system repair times.

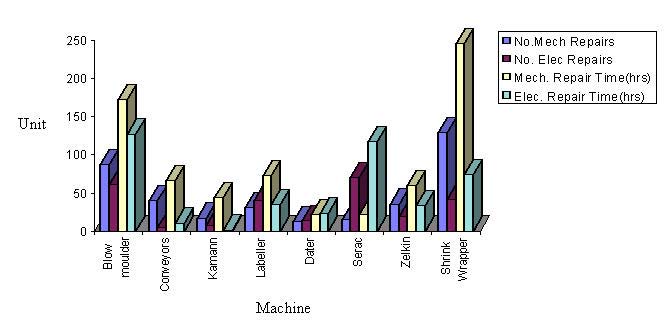

Figure 1.4 presents a breakdown analysis for the repairs and repair times corresponding to the

Figure 1.3 data, but now broken down into the different stages of the process. From Figure 1.4 the following can be observed:-

1. The number of mechanical maintenance requests varied from a low of 13 for the Preston-dater to a high of 129 for the Shrink-wrapper. Electrical maintenance requests ranged from a low of 5 for the conveyor system to a high of 70 requests for the Serac filling machine.

2. The total mechanical maintenance repair times for individual machines varied from a low of 22 hrs. for the Serac and Preston machines to a high of 245 hrs for the Shrink-wrapper machine. In the case of electrical maintenance the repair times varied from a low of 1.5 hrs. for the Kamannbottle un-scrambler to a high of 127 hrs. for the Blow-moulding machine.

Figure 1.4 Pareto Diagram for Repairs and Repair Times

4.2 Analysis-Operator Downtime Reports

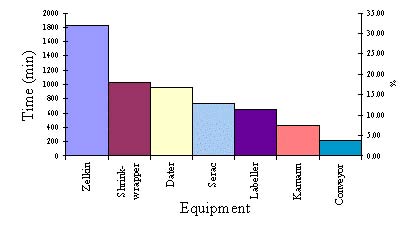

Additional to this data were overall downtime reports as logged by operators. Figure 1.5 shows the Pareto diagram for the causes of downtime. The figure shows that 80% of the production system downtime can be attributed to the Zelkin-capper, shrink-wrapper, Preston-dater and Serac-filling machine. The major cause for the downtime is the Zelkin-capper machine which accounts for 31% of the total system downtime.

Figure 1.5 Pareto Diagram for Equipment Downtime

Further analysis of the shrink-wrapper machine highlighted the fact that uncapped bottles was a significant contributor to its down-time. In other words, there was a downstream effect from failures in the capping machine. Taken all together, the data and Pareto analyses appeared to suggest that solving the ‘uncapped bottles’ problem was a good area to focus maintenance improvement activities.

4.3 Cause and Effect of Uncapped Bottles

Figure 1.6 illustrates the causes of uncapped bottles. The causes were identified through discussions with operators, maintenance personnel, production supervisors and observation of the equipment. Machine failures were due to mechanical, pneumatic, quality and maintenance causes with several potential causes in each category.

Figure 1.6 Cause and Effect Diagram for Uncapped Bottles

5 Function Analysis

The cause and effect diagram served mainly to demonstrate a bewildering array of complexity and thus potential sources of improvement in the system. This kind of analysis, while useful, is not very helpful when it comes to identifying what things we should actually do to improve the system. It was at this point that it was decided to construct functional models of the overall process in order to try and manage the system complexity.

5.1 Problem Definition

To help define the problem definition of “uncapped bottles†more clearly Function Analysis models were developed (Mann, 2002). The system factors that were taken into consideration when developing the Function Analysis models included:

1. Identification of the un-scrambler machine components.

2. Identification of the positive functional relationships.

3. Identification of the negative, insufficient and excessive relationships.

Because such a large factor in the overall maintenance of the system was seen to relate to uncapped bottles, the function analysis models at each stage of the process (Figure 1.1) placed the bottles at the centre of the diagram and paid particular attention to relationships connected to the bottles. The first thing that became apparent during the construction of these models was that the only parts of the process in which ‘harmful’ or ‘insufficient/excessive’ relationships were present in relation to the bottles occurred in the Kamann Unscrambler Machine.

5.2 Function Analysis of Machine For The Unscrambler

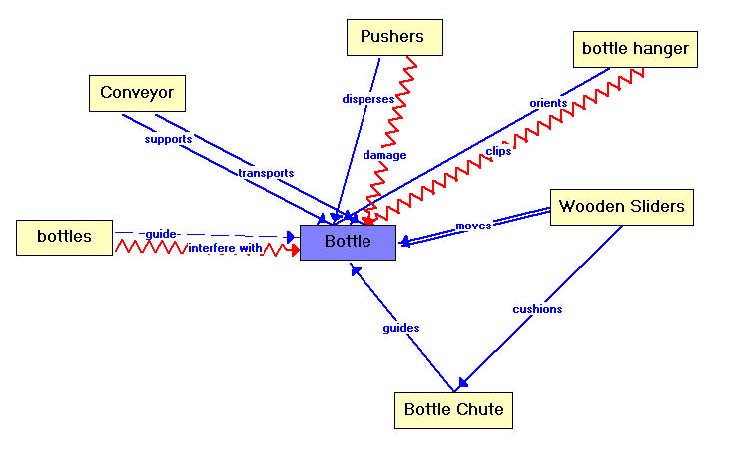

Figure 1.7 illustrates the resulting function analysis model for the un-scrambler machine.

5.2.1 Machine Components

It can be observed that the components of the un-scrambler machine include Bottles, Conveyor, Pushers, Bottle Hanger, Bottle Chute and Wooden Sliders:

Figure 1.7 Partial Function Analysis For Unscrambler Machine

With respect to the harmful relations, manifestations observed by operators included:

(i) Crushed sides walls.

(ii) Indents on bottle base.

(iii) Indents on bottle neck and lip.

What became clear during the overall function analysis process was that after the unscrambler process, although there were no other places where the system had negative effects on the bottle, there were several instances where the bottle could now have a negative effect on other components. The damaged bottles created in the unscrambler, in other words, are then fed to the labelling, dating, filling, capping and packaging stages of the production system and were seen to be causing problems in those parts of the system.

5.3 Problem Definition Redefined

The function analysis models are not only of benefit for defining more clearly the “problem definition†for the un-scrambler machine. They can also be utilised to categorise the problem into “problem type†in order to select the appropriate TRIZ tool to help find a solution. The original “problem definition†was defined as “uncapped bottlesâ€. However, when the function analysis diagrams for the unscrambler were drawn (Figure 1.7) it became apparent that the real problem is damaged bottles exiting the machine after the unscrambling stage. Therefore, it was concluded that the problem definition can be better defined as “defective bottles†entering the production system.

Figure 1.8 illustrates some of the output produced by the analysis of the types of problem identified by the CREAX Innovation Suite software. We will typically use this kind of analysis to guide our approach to solving the problems present in the system. Thus, for example, it suggests the use of ‘knowledge’ and ‘trends’ tools to help explore alternative ways of designing the system. For the purposes of this article, however, we decided to focus on the contradictions tools.

Figure 1.8 Problem Analyser Output For Unscrambler Function Model

6 Contradiction Matrix

6.1 Mapping the Problem

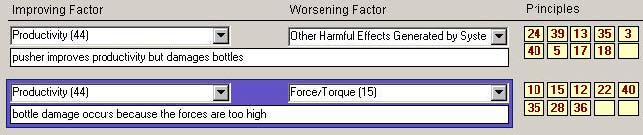

The redefined problem definition of “defective bottles†and the functional relationships defined during the Function Analysis demonstrated the presence of a number of contradictions in the unscrambler system. These contradictions were mapped on to the new Contradiction Matrix (Mann et al, 2003) in order to derive suggested solutions based on the 40 inventive principles (Mann 2002). From Figure 1.7 it was observed that the Pusher, Hanger and other bottles performed both positive and negative effects on the bottle. This indicates the presence of contradictions. These contradictions could be formulated as Physical Contradictions (for example; ‘I want the pusher and I don’t want the pusher’ or ‘I want the hanger and I don’t want the hanger’) or – as we chose to do – be reformulated as technical contradictions. In this case, we need to ask the question ‘why’;

‘why do we want the pusher?’ Answer – to improve productivity

‘why don’t we want the pusher?’ Answer – because the bottle is damaged .

If we ask ‘why’ again – as suggested by Root Contradiction Analysis (Mann, 2002) – for the ‘bottle is damaged’ statement, we get something like ‘because the forces on the bottle are too high’. Examining the problem as a conflict based on these pairs, then, the New Matrix provides the following suggestions (Figure 1.9).

Figure 1.9 Contradiction Matrix Output For Pusher and Hanger Problem Definitions

6.2 Suggested Solutions

The Matrix output suggests a number of possible solutions to (for example) the pusher problem.

These include the following things subsequently incorporated into the system to effectively solve the bottle damage problems:-

Principle 24 – Intermediary: place a protective intermediary layer on key contact points (also Principle 3, Local Quality) on the pusher.

Principle 35 – Parameter Changes (‘increase the degree of flexibility’) – introduction of altered pusher materials such that it was more compliant and thus capable of deforming when coming into contact with the bottles.

Principle 15 – Dynamics; jointing the pusher so that it was capable of deflecting significantly when forces on the bottle became too high.

Principle 40 – Composite Material – re-design the pusher so that it incorporates both stiff and flexible portions (Local Quality again) so that parts that come into contact with the bottle are flexible, while the remainder of the pusher structure provides the desired strength and durablility. In actual fact, the solutions may sound a little obvious in retrospect. This is a common phenomenon in maintenance type problems – where very often the emphasis is on simple, easy to implement problems. The Matrix, on the other hand, is also trying to direct the user towards more profound shifts in the design of the system. In this case, the presence of Principles 17 (Another Dimension), 28 (Mechanics Substitution) and 18 (Vibration) offered useful suggestions as to the longer term trajectory of the unscrambler evolution:

Another Dimension, for example, provoked the concept of gradiented and curved conveyor systems that were better able to guide the bottles and thus eliminate the need for additional mechanical movement mechanisms. Perhaps the incorporation of Vibration (Principle 18) into this solution would offer several other advantages that would move the unscrambler to the more ideal system (the ideal unscrambler is no unscrambler (the bottles unscramble themselves); the ideal pusher is no pusher). Mechanics substitution points towards the use of non-mechanical pushers and hangers – suggesting the use of some kind of either fluid or (more likely) field-based system of performing the guide function. Essentially, it is the problem constraints that will determine which of these solutions can and cannot be deployed.

7. Conclusion

Maintenance efforts can be improved through the use of TRIZ. Its application to the case provides both an insight as to how best define the “problem definition†for the system under investigation. Furthermore, it enables potential solutions to be developed that can be used to both solve the maintenance problem and prevent system failures. In a follow-on article we will discuss how other problems in this yoghurt bottling process maintenance environment were tackled and how the constraints present in a given maintenance situation can be incorporated into the TRIZ problem definition and solution generation process. Constraint management is important in enabling us to achieve the strongest solution possible under a given set of restrictions – both technically and from time, cost and risk perspectives.

8. References

Ashayeri, J., Teelen, A. and Selen, W., (1996), “A production and maintenance planning model for the process industry”, International Journal of Production Research, Vol. 34, No. 12, pp 3311-3326.

Ayerbe, A., (1995), “A Methodology for a Maintenance System Integrated with the Control Modules of a Flexible Manufacturing System”, Proc., 12th. Conf., IMC, Competitive Manufacturing, pp 113-120.

Cooney, J.M.M., Gaiser, M., O’Connor, J.F., (1999), Using Plant Simulation Condition-based- Maintenance of a Clean-in-Place Station, System Operational Effectiveness, 9th International Mirce

Symposium, 1-3 Dec., Mirce Akademy of System Operational Sciences, Exeter, UK.

Cooney, J., (2001), Development and Application of Condition Based Maintenance and

Management in Food Manufacturing, PhD Thesis, National University of Ireland , Cork. Ireland.

Hoffman, W., (1991), “Strategies for Rapid Maintenance, Engineering & Automation XIII”, No. 3.

Lauer, J., Strauß, M., (1993), “Maintenance Information Management in Action”, Engineering &

Automation XV, No. 2.

Mann, D., (2002), Hands on Systematic Innovation, CREAX Press, Belgium.

Mann, D., Dewulf, S., Zlotin, B., Zusman, A., (2003), ‘Matrix 2003: Updating the TRIZ

Contradiction Matrix’, CREAX Press, Belgium.

About the Authors

John Cooney PhD

Academic Researcher at the School of Business and Government, NUI, Cork. He has worked both in academia in Ireland and in the electronics and food industries in Ireland and the UK. He holds a Ph.D. in engineering, MSc. Systems Engineering and BSc. Manufacturing Management and Systems. He is a module tutor and author (MSc in Technology Management) for the Atlantic University Alliance (AUA, Ireland). He is a 1st place recipient of National Maintenance Project Awards, MEETA (1999), “Large Irish Company Categoryâ€.

Darrell Mann

Darrell is a mechanical engineer by background, having spent 15 years working at Rolls-Royce in various R&D related positions, and ultimately becoming responsible for the company’s long term future helicopter and VTOL engine strategies. He left the company in 1996 to help set up a high technology company before entering a programme of systematic innovation and creativity research at the University of Bath. He first started using TRIZ in 1992, and by the time he left Rolls-Royce had generated over a dozen patents and patent applications. He consults on all types of problem situation including an increasing number of ‘maintenance’ issues.

Related posts:

Support us

If you like the TRIZ Journal, please help us by donating towards domain space, admin and technical support.