Case Studies In TRIZ: Flush’n’Go

Editor | On 05, Jun 2005

By: Darrell Mann

Systematic Innovation Ltd

+44 7980 864028

darrell.mann@systematic-innovation.com>

Introduction

This article describes the conception and development of a simple product designed to clean and disinfect domestic toilet units. TRIZ tools were used during each stage of the evolution of the product, not only during the technical aspects of the product development, but also designing the business model, advertising strategy and patent protection. This article will primarily focus on the technical aspects of the programme, only making reference to business issues when they had a direct link to the design of the product.

Like many problem solving case studies, there are holes and discontinuities and occasional blind alleys in the actual sequence of events that unfolded. In some cases those deviations can in themselves offer useful learning points. In others they do not.

Since in this case they tended towards the non-useful and since the primary purpose of the article is to demonstrate a coherent case study with some educational value, elements of the story have been re-framed in order to present what is hopefully a structured process that others can learn from and make use of in many more situations than the specific design solution described here.

Beginning At The Beginning – Market Environment

Toilet cleaners are widely used. Generally speaking, such cleaners are found in three different forms; one a simple solid block that resides submerged inside the cistern to gradually dissolve and hence release the cleaning agent. A second type attaches to the rim of the toilet bowl and thus dispenses its cleaning agents only when the toilet is flushed. Both of these designs carry inherent problems and limitations. The submerged-block device dissolves at a steady rate independent of the rate of use of the unit – hence being potentially wasteful of product if the toilet is used only infrequently. The rim-attached device, on the other hand, dispenses only when the toilet is used, but the performance of this design is inadequate since only a part of the circumference of the rim of the toilet bowl receives any of the cleaning agent dispensed from the product.

A third type of existing toilet cleaner is illustrated alongside the other two in Figure 1. This product takes the shape of an elongated open top cylinder, which is partially filled with a quantity of a solid water-soluble cleansing and sanitizing chemical (54 in the figure).

This and other current toilet cleaning chemicals normally carry a coloured pigment, so that it will impart a visible color to the flushing water when the chemical dissolves. At the throat of the cylinder is a small opening, which is located roughly three quarters of the height of the cylinder from the base. The level of the chemical medium can preferably be at the same level, or is at a distance below the level where the opening at the throat is located.

The top of the cylinder gradually narrows to form an opening of a smaller diameter than that of the base cylinder. Typically this kind of cleaner is suspended in the cistern via a cord hooked over an edge of the cistern tank. This cleaner can thus be positioned so that the level where the opening at the throat is located is at a distance below the actual water level in the cistern tank. Most manufacturers making this kind of product indicate a water level marking on the cylinder above the opening at the throat. Some brands of toilet cleaners prefer to submerge the entire cylinder so that the open top is placed approximately 10 to 20 mm below the actual water level. The unit functions by allowing water to enter the cylinder through the opening at the throat, and also through the open top if it is fully submerged. The water-soluble chemical then dissolves in it to form an active solution with a visible coloration. The intensity of the coloration indicates the strength of the chemical dissolved in the flushing water. Like the simple block variant of the toilet cleaner, this third product type also suffers because the user has no control over the rate of dispensing of the active solution flow. Thus, at times (e.g. when the toilet is not used for a long period), there will be unnecessary discharged of the active solution resulting in an excessively deep coloration of the flushing water, and wastage of the chemical.

Beginning At The Beginning – TRIZ

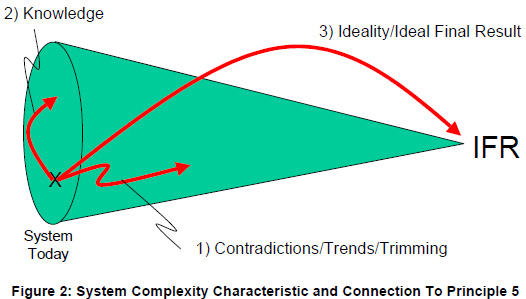

Having established the existence of a market desire for a better product (driven in SE Asiaalignrightby the recent SARS epidemic and a generally increased awareness of the importance ofalignrightgood sanitation), an early choice that has to be made during the deployment of TRIZ isalignrightwhat form of development strategy is to be followed. According to Figure 2 – taken fromalignrightReference 1 – there are three basic evolution routes available. These are, firstly, evolutionalignrightof a current product, secondly, a jump to a different, already existing technology solution,alignrightand thirdly, an approach that begins from a definition of Ideal Final Result.

The choice between these three options is primarily a strategic one: If we have the abilityalignrightto start from a completely blank sheet of paper, then thinking about Ideal Final Result is aalignrightgood start point. The concept of a toilet cleaner product that delivers its useful functionalignrightwithout cost or harm – or rather, ‘the toilet cleans itself’ – was not considered to be analignrightoption for the company given its core competences, available technology and perceptionalignrightof the market needs. Failure to identify a better off-the-shelf alternative technology (i.e.alignrightroute 2)) coupled with the economics of the particular business situation, in fact, forced thealignrightcompany into the first ‘Contradiction/Trends/Trimming’ route. The decision to take analignrightexisting system and evolve it in a more ideal direction was thus a strategic one based onalignrightthe specific constraints of the situation. In other circumstances, the company might wellalignrighthave chosen a different route.

Conflicts & Contradictions

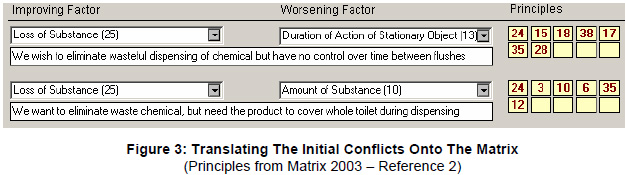

Having made the decision that the project was going to evolve one of the existing productalignrightconcepts, attention quickly focused on what could be seen from the choices available inalignrightthe market as the key contradiction; where on the one hand we desired to eliminate wastealignrightof product, and on the other we wanted to ensure that the whole of the toilet was cleaned,alignrightand that we had no control over the time between flushes. These conflicting requirementsalignrightwere then mapped onto the new Contradiction Matrix as illustrated in Figure 3:

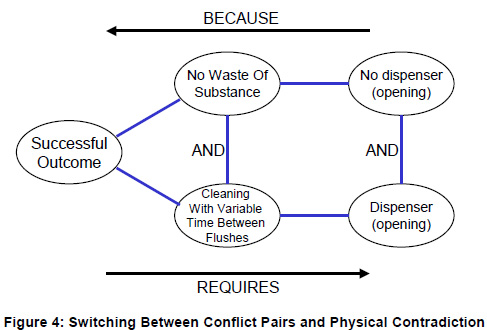

As is often the case, we could also see a clear physical contradiction – we wanted thealignrightdispenser immediately after a flush, but we did not want a dispenser in the period of timealignrightbetween dispensing and the next flush. The correlation between physical contradictionalignrightand conflicts is illustrated in Figure 4 – a general model found in Reference 3 for switchingalignrightbetween the two different contradiction types.

In order to generate a cluster of possible ideas, we then proceeded to work through thealignrightInventive Principles suggested by the conflict-pairs and strategies for solving PhysicalalignrightContradictions separated in both time and on condition (which, as we know, ultimatelyalignrightcorrelate to Inventive Principles in any event). During this phase our aim was to generatealignrightas many solutions as possible – in all we ended up with around 100 – and to avoidalignrightcritiquing them until the next, analytical phase. Thus we made sure to separate out thealignrightvery different tasks of generating ideas and evaluating them. During the evaluation period,alignrightthen, our minds were constantly focused on distillation rather than filtering of ideas.

1) Contradictions/Trends/Trimming

2) Knowledge

3) Ideality/Ideal Final Result

Combination of individual ideas, in other words, was considered more important than elimination of weak ideas.

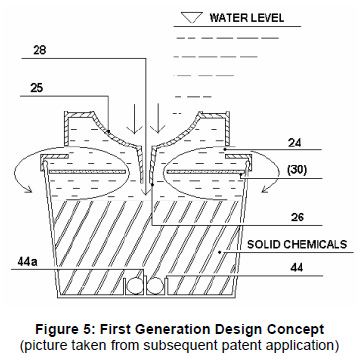

The eventual solution that emerged from the session looked like the picture shown inalignrightFigure 5. Without going into the minute details of the idea generation process, the keyalignrightinventive steps that found their way into this first conceptual solution comprised:

• Use of a highly concentrated, solid, dissolvable chemical compound (Principlealignright35)

• Incorporation of a semi-permeable membrane between this chemical and thealignrightwater in the cistern (Principle 24)

• Use of a ‘preliminary action’ (Principle 10) so that dispensing of the cleaningalignrightchemical occurred only the level of the water in the cistern dropped to a pointalignrightwhere it no longer covered all of the device, the required delay in action beingalignrightfacilitated by temporarily holding an amount of water in the device at a higheralignrightlevel than the level in the cistern (Principle 17).

The figure also serves to explain how the auto dispenser unit was designed to operate atalignrightthis stage in its evolution: Firstly, we need to consider an initial situation where the autoalignrightdispenser unit is placed at the base of an empty cistern tank immediately after the toiletalignrighthas been flushed and the flushing water is filling up the tank. Water entering the cisternalignrightwill also enter the unit through the apertures (24) in the sidewall of the cap member (25),alignrightand into the enclosed space (28). As water comes in contact with the solid chemicalalignrightmedium via the semi-permeable membrane (30), an active solution is formed and wateralignrightturns the colour of the chemical medium. As the water level in the cistern continues to rise,alignrightit will eventually completely cover the device, which stays on the bottom of the cisternalignrightthanks to the weights (44).

During the next flushing action then, the water level inside the cistern tank drops belowalignrightthat level of the apertures (24) in the sidewall, the water contained in the fluid retainingalignrightdepression (25) will move down by gravity through the drain opening slower than the ratealignrightof drop of the water level in the cistern as a whole. This happens thanks to the heightalignrightdifference between the concave feature and the base of the aperture (24), and thealignrightjudicious sizing of the passageway (28). As water descends from this concave region, italignrightdisplaces the active solution of similar amount from the enclosed space so that it flows outalignrightof the dispenser via the opening (24) into the surrounding water.

At this stage in the design process, it was decided that the basic concept needed to bealignrightturned into a physical prototype. Here was the time when details like the sizing of holesalignrightand weights needed to be calculated, and as such the design story switched from thealignrightworld of Inventive Principles to the world of mathematics. Several iterations were trialedalignrightbefore an appropriate combination of dimensions was achieved. A late-period prototype isalignrightillustrated in Figure 6.

Having achieved a design with all of the initially specified functionality, there was a strongalignrightinclination at this stage in the development to freeze the design and begin the transition toalignrightproduction. This appears to be a type of psychological inertia common in many designalignrightsituations. One that in too many cases proves to be too difficult to fight.

In this case, we forced ourselves to think about ‘the next contradiction’. This processalignrightbegan by asking the very simple question ‘what would we like to improve about thealignrightdesign?’ In this case we had three answers:

1) at the end of the life of the product, when all of the chemical has beenalignrightdispensed, the user has to somehow retrieve the spent unit from the base of thealignrightcistern.

2) Under certain conditions, the water flowing into the cistern could cause the unitalignrightto fall over, which then impaired its dispensing capability. The problem couldalignrighthave been solved simply by providing the user with instructions about where notalignrightto position the device in the cistern, but it was decided that this was a fall-backalignrightcompromise and not an ideal solution

3) Could we reduce the number of parts and hence the manufacture costalignright

Having stated these three desires, we then set about ‘going around the contradiction loop’alignrightagain by asking ‘what is stopping us from achieving the aims?’ In the case of the first aim,alignrightthe thing stopping us was that there was no force present to cause the device to move atalignrightany point during its life. We were missing a field in other words. In the end, we determinedalignrightthat the field we were missing had something to do with buoyancy – since if we couldalignrightmake the device float when the chemical was spent, then it would allow the user toalignrightremove it without getting wet hands.

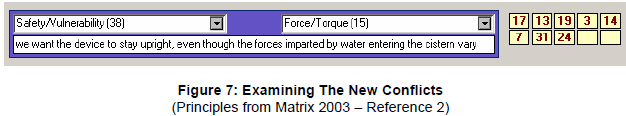

In the case of the second issue, the conflict pair we mapped the problem to wasalignright‘vulnerability’ versus ‘force’ – Figure 7.

In the third area, we identified a very cheap source of weight (actually a glass marble) andalignrightre-designed the base of the unit such that the marble could be push-fit into a moulded-in feature, and we imposed a constraint on the other two design aims that they had to be achieved without adding any additional components – in other words, the new functions had to be delivered by the existing five components – base, weight, cap, membrane and chemical.

Using a process similar to that in the first design iteration, the Inventive Principles were used to generate a pile of individual ideas that could subsequently be distilled into a best combination. The eventual design solution that emerged from this process is shown in Figure 8.

Hopefully the application of Principles 17, 14 and 31 can all be clearly seen in this new design. The way it operates is similar to before, only now, by adding curvature to the base of the unit, the already-present counter-weight give the unit self-righting properties.

Further, by creating an air-pocket (air – free resource!) inside the unit, it was possible to provide the required buoyancy force.

Having obtained the conceptual solutions, there then followed another inevitable round of calculations in order to obtain the right performance attributes. The sizing of the airpocket, for example, required detailed calculation in order to ensure that the device only floated when all of the solid chemical cleaner had been dispensed. Another question that had to be answered by mathematics rather than Inventive Principles.

At this point, we could have chosen to conduct another design iteration – identifying a new round of contradictions and seeking to resolve them. We decided, however, that business issues should drive the decision making process at this stage, and the design was frozen.

Intellectual Property Matters

Allowing business factors determine design-freeze is one thing, but intellectual property is another. Getting a product on the market is one issue and protecting the future is another. Neither is sufficient by itself. And so, while the work to transition the product to massmanufacture progressed, TRIZ tools were deployed again to help in the configuration of the strongest possible patent application.

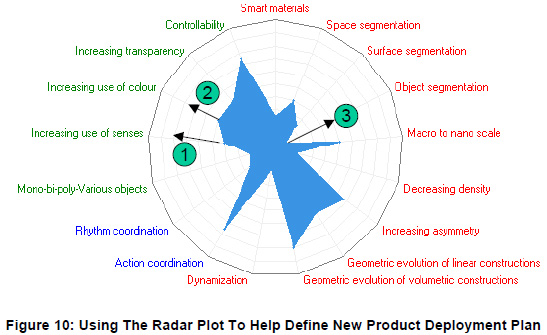

In this author’s experience, the primary tool for achieving future-proofed patents is the Evolution Potential concept (Reference 1 again or Reference 4). Figure 9 illustrates a summary level radar plot for the product design illustrated in Figure 8. In practice, we actually constructed plots for each of the four components and used them to help configure the patent text and claims, but we need not get into such detail here in order to demonstrate the main issues.

By way of a quick reminder of the Evolution Potential concept, each of the spokes on the plot represents one of the trends of discontinuous technology evolution. The blue shape in the figure illustrates the current position of the product along those trends, and hence all of the white space represents evolution jumps that have not yet been made. The key aspect of these plots as far as intellectual property protection is concerned is that, we wish to include any and all such – physically realizable with current technology – jumps in the invention disclosure in order to ensure that we own them rather than allowing a competitor to come along in the future and claim them for themselves.

We can also use the radar plots as the foundations of a future product evolution strategy. The toilet cleaner product emerges into a highly competitive fast-moving consumer goods market in which there is an expectation from customers that there will be a succession of new and improved products. What the radar plot allows us to do in this situation is provide a framework of ‘all possible’ evolution jumps, from which a sequential new product deployment plan can be built. The details of how this process was conducted in this particular case are necessarily subject to commercial confidentiality.

However, since the first of the evolution jumps has already been presented to the market, we can offer an illustration of the radar plot in action when we say that the evolutionary jump to a product engaging additional human senses – a trend jump illustrated in Figure 10 – in this case a scented version of the product was deemed to be the most appropriate product upgrade on the market.

Summary & Conclusions

The preceding description depicts the creation of a ‘more ideal’ design solution to a simple product.

The story started with a business decision that the company was in the toilet cleaner dispenser business and wanted an improved version of an existing product type. This constraint played a large part in determining the mix of TRIZ tools used to create the ‘more ideal’ solution.

We used the simple questions ‘what would we like to improve?’ and ‘what’s stopping us?’ to configure design conflicts and contradictions that would then in turn allow us to use a selection of Inventive Principles to generate a range of possible solution directions. We then sought to combine the best of these into a single coherent design concept.

Once we had a concept, the TRIZ tools were put on one side to allow the mathematics and the detailed design to take place. We then reached the point of having a working prototype.

We could have decided to freeze the design having reached this point, but the business constraints permitted us to conduct another round of ‘what would we like to improve/what’s stopping us’ questions. As is frequently the case, solving a second round of conflicts turns an okay design into one which is much stronger. Again, once the TRIZ solution generation tools had done their job, the mathematics and detailed design took over.

After this second design iteration, the business constraints drove a decision to freeze the design. If the opportunity to go around the loop had been there, we would have taken it. In any event, we wanted to create a piece of intellectual property doing the best possible job of future-proofing the design. The Evolution Potential concept allows a thorough identification and examination of all known successful evolution jumps and their possible relevance to the likely future evolution of the product. In addition to helping us to write the strongest possible invention disclosure, the radar plots also served as a means of plotting out a plan of future product enhancements.

The ‘Flush’nGo’ product discussed in this case study is currently on sale in supermarkets and convenience stores in Malaysia. It will shortly be launched in China.

References

1) Mann, D.L., ‘Hands-On Systematic Innovation’, CREAX Press, 2002.

2) Mann, D.L., Dewulf, S., Zlotin, B., Zusman, A., ‘Matrix 2003: Updating The TRIZ Contradiction Matrix’, CREAX Press, 2003.

3) Mann, D.L., ‘Hands-On Systematic Innovation For Business & Management’, IFR Press, September 2004.

4) Mann, D.L., Dewulf, S., ‘Evolutionary-Potential™ in Technical and Business Systems’, TRIZ Journal, June 2002.