TRIZ Patterns of Evolution as a Means for Supporting History of Technology: Analyzing the Brunelleschi’s Dome Cranes

Editor | On 04, Jul 2003

By: Gaetano Cascini (1), Romano Nanni (2), Davide Russo (3)

(1) Università degli Studi di Firenze

Facoltà di Ingegneria, Dip. di Meccanica e Tecnologie Ind.li

e-mail: gaetano.cascini@unifi.it

(2) Museo Leonardiano – Biblioteca Leonardiana

Comune di Vinci (FI)

e-mail: r.nanni@comune.vinci.fi.it

(3) Università degli Studi di Firenze

Facoltà di Ingegneria, Dip. di Meccanica e Tecnologie Ind.

e-mail: regentind@inwind.it

ABSTRACT

The use of TRIZ as a non-technical problem solving method is rapidly growing and more and more case studies in several fields of application are spreading into the TRIZ community, enriching a knowledge base created as an extreme synthesis of the patent database.

In this paper a TRIZ approach is proposed as a means to support History of Technology research, therefore still as a technical application of the theory, even if not comprised by the original source of knowledge.

The efficiency of the method has been tested by analyzing the cranes designed by Filippo Brunelleschi for the construction of the S. Maria del Fiore Cupola in Florence.

1. Introduction

Patterns of Evolution are one of the most powerful TRIZ tools both for identifying systems evolution potentiality and to speed up the generation of new solutions for technical problems; a more advanced use of the tool allows strategic forecasting of medium/long term scenarios as described by [Domb 2000, Mann 1999, Sawaguchi 2001, Zlotin and Zusman 2001] . New technology trends have been added to the original ones discovered by the first TRIZ researchers as in [Mann 2002] ; further studies have demonstrated the validity of these patterns of evolution even in other fields like business and management, arts, biology etc. [see for example Domb 2003, Mann 2000, Timokhov 2002, Zlotin et al. 2001] .

Looking at the technical field, several studies have been performed by Altshuller himself to check the applicability of the patterns in any area of technology (according to Zlotin et al. 2001, though no publications were presented by Altshuller about this topic, he repeatedly addressed such a task in numerous seminars and discussions). Besides few works are available about history of technology trends analysis and, more specifically, in authors’ knowledge no studies at all have been performed applying TRIZ analysis to Italian Renaissance engineers.

In this paper TRIZ patterns of evolution have been used to compare the cranes designed by Filippo Brunelleschi to build the S. Maria del Fiore Dome, in Florence; as a result, an innovative application of TRIZ tools as a means for aiding History of Technology researchers is presented. More specifically, the aim of this work is defining a set of criteria to compare historical inventions in order to provide a temporal classification as well as an evaluation of their subsystems functionalities.

2. Historical background

The 15th century used to be a very prosperous age for Florence: at that time, most of the marvelous architectural jewels of the town were built and there was a plenty of building sites (Palazzo Pitti, S.Lorenzo Basilica, S.Spirito Basilica, Ospedale degli Innocenti, Sacrestia Vecchia of S.Lorenzo, La Cappella de’ Pazzi, S.Maria degli Angeli, etc.). Among all these buildings, Santa Maria del Fiore (Our Lady of the Flower, or ‘of Florence’) cathedral was the most impressive one.

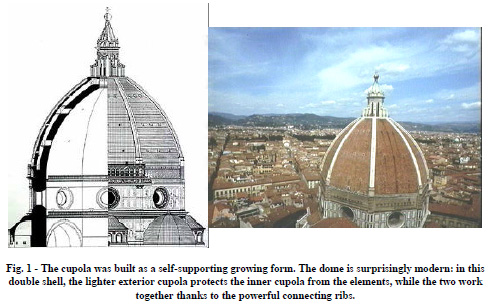

This is the environment of the following historical excursus that starts from the year 1420: the erection of the Florence cathedral was almost completed and the construction of the Cupola started. In order to accomplish such an ambitious project “Opera del Duomoâ€, the organization responsible of the building, assigned the task to the most famous architect of that age: Filippo Brunelleschi, who confirmed his fame by presenting a revolutionary project. For the first time it was proposed to build such a big dome without any scaffolding. The first reactions to this proposal were completely adverse and Brunelleschi was derided for his “too advanced†idea. Nevertheless he eventually convinced Opera del Duomo of the Cupola feasibility and between 1420 and 1436 it was masoned under the incredulous eyes of colleagues and denigrators.

In the meanwhile Brunelleschi won even the bid to build the dome lantern. This is a construction with a not negligible size: a parallelepiped octagonal plan 15 meters high, with the basis inscribed into a 10 meters diameter circle; the top of the lantern is surmounted by an impressive bronze sphere 2 meters wide, that at that time used to support a 4 meters high cross constituting the top of the building.

2.1 Filippo Brunelleschi

Brunelleschi was born in Florence in 1377. During his adolescence he worked as a goldsmith in “Compagnia della Seta†(the silk corporation). The fertile environment of Italian Renaissance allowed him to learn literature and maths fundamentals, while his genius let him soon excel as well in arts as in mechanics. In 1402 he settled in Rome where he cooperated with Donatello. In 1404 he came back to Florence and started working on the construction of S. Maria del Fiore apsis. During the Renaissance, engineers used to grow as artists or, according to the “artist†ancient meaning, as artisans, i.e. Masters of Arts (in this sense art should be intended as any kind of manual or spiritual ability). In most cases Renaissance Engineers used to be also artists (according to the actual meaning of this word). Brunelleschi rightly was one of the most representative masters: as a confirmation, in the years between 1405 and 1420 he dedicated at the same time his efforts to sculpture and civil engineering.

During the construction of S. Maria del Fiore Cupola he was the responsible, or at least cooperated to the erection of several important Florence buildings: the dome star in S.Lorenzo Basilica, Cappella de’ Pazzi, the Rotonda.

He died in Florence in 1446 where he was buried first in Campanile di Giotto, later inside the Cathedral.

His multidisciplinary experience clearly is, as well for other Renaissance Masters like Leonardo da Vinci, the key of his inventiveness.

2.2 The Environment

In order to understand how remarkable was the Brunelleschi project, it is worth highlighting not only the construction of a dome without any scaffolding, but also the erection of the lantern in a building yard at more than 90 meters from the ground, on a small platform based on a curved surface!

The month following the start of the works on the lantern Brunelleschi died leaving an even more surprising “inheritanceâ€: the constraint of loading the cupola as much as possible. That’s why the lantern frame was built with huge marble blocks to be lifted on the top of the dome and positioned with extreme precision.

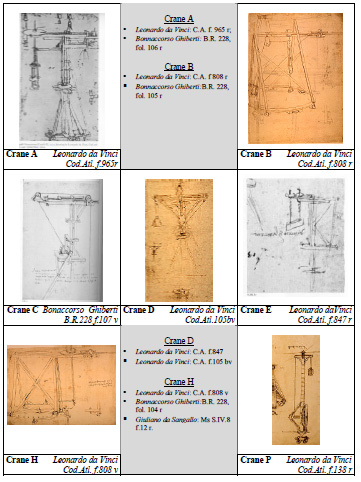

A bunch of cranes were designed by Brunelleschi, but neither drafts, nor wooden models survived but the drawings of Leonardo da Vinci, Giuliano da Sangallo and Buonaccorso Ghiberti, therefore it is still a mystery which of these cranes were effectively used, how and for what. In facts, Brunelleschi used to say that ideas and projects shouldn’t be divulged since few people could understand them and most of all they could be stolen and used as proprietary. The present work is aimed to compare these cranes drafts according to the TRIZ patterns of evolution in order to give a contribution to the comprehension of the Brunelleschi Dome construction.

2.3 Historical sources: a traditional approach

The “Opera del Duomo†archive stores a very detailed report on the expenses for the erection and the maintenance of S. Maria del Fiore cathedral. This data are essential but not sufficient for historical analyses, due to the aforementioned Brunelleschi mania of destroying any information about his work.

Nevertheless Brunelleschi couldn’t hide the machines used in the building yard on the top of the Dome, which were visible from every place in the town. Moreover it is known that some drafts were copied by people working with him.

Among all the drafts representing the Brunelleschi cranes, those made by Leonardo represent the most comprehensive collection and are much clearer and rich of constructive details than any other. It is worth mentioning that Leonardo, born in Vinci, settled in Florence in 1452, when the works on the lantern were almost completed; besides he started working in the workshop of Andrea del Verrocchio who won the bid to build the bronze sphere for the top of the lantern, therefore he certainly had the opportunity to gather information about the Brunelleschi machines.

3. Brunelleschi’s Dome: the cranes

The selection of the drawings to be analyzed has been performed according to the following principles:

1. Historical relevance: the cranes should be related to the S. Maria del Fiore building yard.

2. Functional congruence: the machines must be able to lift and position masonry loads.

3. Structural congruence: the Vitruvio type cranes have been omitted as well as ground winches (to be moved by means of animals), in order to take into account just a homogeneous set of machines and to perform the comparison at a deeper detail level.

The selected cranes belong to the following documents:

* Leonardo da Vinci: C.A. f.965 r; C.A. f 808 r; C.A. f.105 bv; C.A. f. 847 ; C.A. f 808 v.

* Giuliano da Sangallo: Ms S.IV.8 f.12r.

* Buonaccorso Ghiberti: B.R.228 f.106r; B.R. f.105r.; B.R.228 f.104r.

All these machines share the lack of knowledge about when and where they’ve been used in the S.Maria del Fiore Dome building yard. Moreover it is even not known if they were really built. By means of a basic functional comparison the equivalent cranes have been grouped together and a reference initials has been assigned to each class, as shown in Table. 1.

4. Comparison criteria

Since no information is available about the size of the cranes the comparison has been applied to the conceptual scheme of the machines in terms of design solutions, as they had similar dimensions; nevertheless it doesn’t look as a limitation for the aim of this work according to the assumption that a more ideal solution was conceived later by Brunelleschi, apart from its practical embodiment.

The analysis takes into account four basic features:

1. Load positioning, degrees of freedom: analysis of the capabilities of a crane to move the load within the work volume; accuracy and control of the position; number of operators employed.

2. Load lift, stop mechanism: comparison of the lifting functionality in terms of height, speed, safety, stop capability.

3. Internal structure, frame: frames comparison in terms of shape, rational usage of the materials, crane robustness.

4. External stability: identification of the interactions of the crane with its environment (supersystem) to highlight the necessity of scaffolds, stays, anchoring means.

The above listed crane features have been compared according to a set of relevant inventive principles and patterns of evolution:

§ Inventive Principles:

Ø Separation

Ø Partial/excessive action

Ø The other way around

Ø Self-service

§ Patterns of evolution:

Ø Dynamization

Ø Segmentation

Ø Geometric evolution (dimensionality)

Ø Mono-bi-poly systems

Ø Controllability

Ø Trimming

Ø Decreasing human involvement

4.1 Comparison matrix

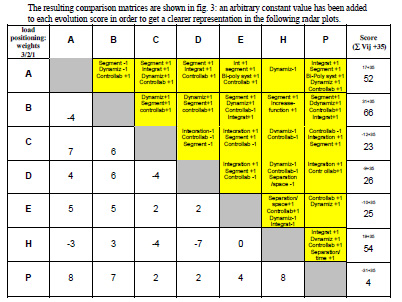

Basically the method consists of performing a one-to-one comparison between the selected machines; the four basic features representative of the machines characteristics are compared on the basis of the selected principles and patterns of evolution.

The comparison is operated by means of a set of NxN square matrices, each corresponding to one of the above defined basic features, where N is the number of the examined machines. The (i, j) cell in the right-top half of the matrix contains the result of the comparison between the ith and the j-th machines: an exemplary content is represented in figure 2.

The principles/evolution patterns not concerning any difference between the two machines under comparison are omitted. Besides, a “-1†value means that the i-th machine of the first column is at least a step forward in the evolution than the j-th machine of the first row; vice versa for a “+1†value.

The result of such a comparison is reported in the left-bottom half of the matrix, in the (j,i) cell, (with a sign inversion): such a value is determined as the sum of the partial values in the (i,j) cell and it represents the evolution balance of the pair of examined machines. For example, the comparison between the cranes A and C in terms of load positioning and degrees of freedom gives the following result:

Segmentation +1: the crane A is a step forward since the horizontal translation of the load and the lift mechanism are fully independent due to a segmentation

Dynamization +1: the crane A is more “dynamized†and it has a greater controllability thanks to the major number of degrees of freedom of the positioning devices

Integration +1: the crane A makes use of a triple screw system in order to control the horizontal orientation of the load

Since different inventive levels are typically associated to the inventive principles and patterns of evolution adopted for the comparison, the evolution balance can be evaluated by means of a weighted sum according to the following classification:

– Class A (weight 1÷3): Separation, Self-service, Dynamization, Geometric evolution;

– Class B (weight 1÷2): Segmentation, The other way around, Partial/excessive action;

– Class C (weight 1): Mono-bi-poly systems, Controllability, Trimming.

The sensitivity of the proposed procedure as a function of these weights has been checked by means of three different analyses detailed in the following section: minor variations of the results have been observed.

Once the analysis for a given feature has been completed, an evolution score is evaluated for each machine by summing all the corresponding evolution balances. Such a score can be adopted as a ranking function of the machines in terms of technical evolution of the examined feature.

The analysis can be repeated for all the above defined features and summing the evolution scores associated to each comparison feature provides an overall result.

4.2 Summary of the proposed method

The above described technique is basically constituted by six steps, as follows:

1. Analysis of the machines to be compared in order to identify a set of homogeneous comparison features.

2. Identification of the relevant inventive principles and patterns of evolution to compare the features selected in step 1.

3. One-to-one comparison of each feature of the machines according to the principles defined in step 2.

4. Each comparison performed in the previous step provides an evolution balance between the machines pairs, taking into account the innovation level associated to each principle.

5. Evaluation of the feature evolution score as the sum of the evolution balances associated to each machine.

6. Evaluation of the machine evolution score as the sum of the scores determined for the single features.

It is worth to notice that the step 3 requires some knowledge about the technology of the historical period of the examined machines; therefore a preliminary study of the relevant topics and/or a strict cooperation with experts of the field is absolutely necessary.

4.3 An alternative method

The method described so far collects and averages all the results associated to each machine both in terms of comparison feature and TRIZ pattern of evolution and is applicable even to inhomogeneous machines.

In case of homogeneous machines, an analogous comparison can be obtained with the following procedure:

1-3. Same steps as described in section 4.2 (therefore the top-right half of the comparison matrix is invariant).

4. The bottom-left half of the matrix is filled by assigning the following values:

a. +1 – if the evolution balance is positive;

b. -1 – if the evolution balance is negative;

c. 0 – else.

5-6. Same steps as described in section 4.2.

Such a method is focused on the evolution of the selected functionalities of the examined machines: it is not important how much a machine is conceptually advanced, rather than how many features are better than in the other machines. In other words a homogeneous development of all the functionalities of a machine is privileged compared to an extreme evolution of a single feature (even to the detriment of the other features).

5. Results and discussion

The method described in sections 4.1-4.2 has been applied to the cranes selected in chapter 3, by focusing the analysis on the four identified basic feature of these machines. The following weights have been adopted according to the principles classification described in section 4.1:

– Class A – 3;

– Class B – 2;

– Class C – 1.

The resulting comparison matrices are shown in fig. 3: an arbitrary constant value has been added to each evolution score in order to get a clearer representation in the following radar plots.

The evolution score obtained by means of the comparison matrices can be efficiently represented by means of radar plots as shown in Fig. 4. The resultant evolution score is reported in Fig. 5, as well as the final rank of the machines.

5.1 Sensitivity analysis

In order to evaluate the sensitivity of the proposed technique as a function of the adopted weights,

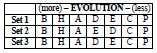

the same procedure has been followed with different parameters, as reported in Table 2. The resulting ranks are summarized in Table 3.

Table 2. Weights assigned to the principles classes for the sensitivity analysis

Table 3. Evolution rank of Brunelleschi’s cranes as a function of the weight set.

No relevant qualitative variations can be observed between the results obtained with different weights sets, therefore confirming the stability of the proposed method.

The same analysis has been accomplished also according to the alternative method described in section 4.3. In this case just the first set of weights has been adopted. The resulting rank is reported in table 4.

![]()

Table 4. Evolution ranks of Brunelleschi’s cranes according to the two methods described in section 4.

In this case some minor differences can be observed: while the cranes D and A are quantitatively almost equivalent for the standard method as well as for the alternative one, it could be surprising the result concerning the pair P, C. Inversely, it should be remembered that the alternative method gives greater prominence to the homogeneous development of all the functionalities of a machine apart from the quantitative differences of the single features. In this case, the crane P is a machine at the end of its evolution path, with a homogeneous development of all its basic functionalities. Besides the crane C presents an innovative solution to move the load along a radial direction, in spite of the overall complexity that is augmented. It is worth noting that the quantitative difference between P and C is still minimal.

5.2 Validation

In order to check the reliability of the proposed methodology the resulting crane ranks can be compared with the available historical data, briefly summarized in the following paragraphs.

Crane P

The crane P is the oldest one, since similar architectures can be found during the Romans age. It was certainly used for the construction of the basis of the S. Maria del Fiore cathedral and probably later according to the availability of a planar surface to move the trolley.

Crane C

The crane C was used to transfer building materials from a floor to another; it is clearly an evolution of the crane P, easier to use since it doesn’t require the same anchoring means of the preceding machine. It was presumably used to build the octagonal walls of the Dome.

Crane D

The crane D is the one with major lack of information: some researchers state that it was used for the erection of the Dome.

Crane E

The Leonardo draft of the crane E reports a note that identifies an element of the middle of the lantern: “viticcio da lanternaâ€.

Crane A

The use of the crane A is still debated: several historians state that it was used on the top of the Dome, even if this theory is in contrast with the compatibility of such an huge crane with the limited space available along the octagon perimeter. The crane A certainly is an evolution of a machine used during the preliminary stages of the Dome construction, and it can be affirmed that it has been probably used to build the walls of the lantern. In facts, in the examined draft the load applied to the crane has a characteristic shape, that looks like a brick of the lantern columns.

Crane H

The crane H has most probably been used for the construction of the lantern walls. It certainly appeared some times before the crane B.

Crane B

The crane B was the last machine to be used on the top of the Dome for the erection of the pyramidal roof of the lantern. It presents a set of very innovative technical solutions, first of all the revolutionary centering means, so that it is arguable if it has been effectively conceived by Brunelleschi, or later by Leonardo himself.

A survey of these historical data confirms a great correspondence with the rank output by the proposed methodology as described in the previous section. It can be stated that sorting a set of machines on the basis of a TRIZ comparison in terms of technical evolution is a reliable means to give a suitable contributions to History of Science and Technology research.

6. Conclusions

In this paper a TRIZ based analysis of Renaissance machines has been adopted to aid historians classification. The methodology has been applied to the cranes designed by Filippo Brunelleschi to build the Dome of the S. Maria del Fiore Cathedral.

The proposed method has been validated by comparing the resulting machines rank with the available historical data. Moreover the reliability of the method has been checked by means of a sensitivity analysis as a function of the variation of the analysis parameters. The authors are going to extend such an approach to the analysis of a set of Leonardo’s inventions in the textile field.

References

Domb E., Strategic TRIZ and Tactical TRIZ: Using the Technology Evolution Tools, The TRIZ Journal, January, 2000.

Domb E., TRIZ for Non-Technical Problem Solving, The TRIZ Journal, April, 2003.

Mann D., Application of Triz Tools in a Non-Technical Problem Context, TRIZCON 2000.

Mann D., Hands-On Systematic Innovation, Creax, 2002.

Sawaguchi M., Study of Effective New Product Development Activities through Combination of Patterns of Evolution of Technological Systems and VE, Proceedings of TRIZCON2001, The Altshuller Institute, March, 2001.

Timokhov V. I., Natural Innovation: Examples of Creative Problem Solving in Biology, Ecology, and TRIZ, CREAX, ISBN 5-88912-004-2, 2002.

Zlotin B., Zusman A., Directed Evolution Philosphy, Theory and Practice, Ideation International Inc., 2001.

Zlotin B., Zusman A., Kaplan L., Visnepolschi S., Proseanic V. and Malkin S., TRIZ Beyond Technology: The theory and practice of applying TRIZ to non-technical areas, The TRIZ Journal, January, 2001

Historical references

Bartoli Lando, La rete magica di Filippo Brunelleschi le seste,il braccio ,le misure, Nardini Editore, 1977.

Benevolo, Storia dell’architettura del Rinascimento, GLF editori Laterza, 2002.

Besson J., Il Theatrum instrumentorum et machinarum, Edizioni dell’Elefante, 2001.

Boni Bruno, La palla di rame di S.Maria del fiore, in Notiziario vinciano. – A. 2, n. 5, 1978.

Carpiceci Alberto Carlo, “Leggere†i disegni di Leonardo, in Notiziario vinciano n°1, 1977.

Cerizza A., Benni M., Disegni e simulazioni tridimensionali di macchine di Taccola e Francesco di Giorgio. Disegnare le macchine: ieri e oggi.

Cianchi M., Le macchine di Leonardo, Becocci, 1982.

Di Pasquale S.. Leonardo, Brunelleschi and the machinery of the Construction site, in Leonardo da Vinci engineer and architect. – Monreal : Monreal Museum of Fine Arts, 1987.

Du Colombier P., Les chantiers des cathedrales: ouvriers, architectes, sculpteurs, Picard, 1973.

Galluzzi Paolo, Renaissance Engineers From Brunelleschi to Leonardo da Vinci, Giunti editore, 1996.

Galluzzi Paolo, The Art of Invention and the Renaissance Engineers, Proceedings of the 30th SEFI Annual conference, Firenze, 8-11 September 2002.

Gelb, M., How to think like Leonardo da Vinci, Dell Publishing, 1998.

Leonardo da Vinci, Il Codice Atlantico di Leonardo da Vinci : edizione in facsimile dopo il restauro dell’originale conservato nella Biblioteca Ambrosiana di Milano, Giunti Barbèra, 1973- 1975.

Leonardo da Vinci, I Codici di Madrid [nella] Biblioteca nazionale di Madrid, Giunti Barbèra, 1974.

Reti Ladislao, Tracce dei progetti perduti di Filippo Brunelleschi nel codice Atlantico di Leonardo da Vinci, IV Lettura Vinciana, G.Barbera editore, 1965.

Saalman H., Filippo Brunelleschi : The Cupola of Santa Maria del Fiore, Zwemmer, 1980.

Scaglia Giustina, Alle origini degli studi tecnologici di Leonardo- XX Lettura vinciana, Giunti Barbera editore, 1981.

Singer C., Holmyard E.J., Hall A.R., Williams T. I., Storia della tecnologia – Le civiltà mediterranee e il medioevo circa 700 A.C.-1500 D.C., Bollati Boringhieri editore, 1993