Process Modeling, Simulation, and TRIZ: An Innovative and Symbiotic Solution

Editor | On 01, May 2004

ABSTRACT

The application of TRIZ necessitates the analysis and understanding of a process [1] [2] .

In this spectrum of understanding, the process is either:

1. not very well understood at all (unfortunately, all to often); or

2. understood but not documented, e.g., the knowledge of the process is embodied inthe minds of experts; or

3. documented but not modeled, e.g., written documentation exists; or

4. modeled but not in a form that can be simulated, e.g., process diagrams [3] ; or

5. modeled and in a form that can be simulated [4] .

As the interactions among the processes of a system increase in complexity, the value of process modeling and simulation to the analysis portions of the TRIZ algorithm likewise increases, in that it becomes harder and harder to determine where innovations are best applied [5] . Processes that are difficult to emulate due to their large scale and/or life threatening characteristics compound this issue [6] .

To emphasize this point, we will embark on a Homeland Security Simulation (HSS). The focus of the HSS will be a terrorist threat in the form of a lethal virus [7] , coupled with the manufacturing and dispersal of its counteragent, i.e., a serum [8] . The combination of this threat, the detection of the threat, the manufacturing of the serum, the delivery of the serum to treatment centers, and the testing and treatment of patients, constitutes a process. The goal of this exercise is to demonstrate that:

1. the effectiveness of TRIZ analysis on a process increases as the understanding of the process increases;

2. process modeling and simulation dramatically increases the understanding of complex process interactions;

3. process modeling and simulation supports TRIZ Principle 26, Copying, “A simplified and inexpensive copy should be used in place of a fragile original or an object that is inconvenient to operate [9] ;â€

4. process modeling and simulation directly supports the TRIZ Size/Time/Cost (STC) what-if operator [10] .

INTRODUCTION

For the purposes of this discussion, we will make the following simplifying assumptions:

1. To create a baseline performance for the process, we will simulate the results of a viral attack on a small group of contained individuals, i.e., an aerospace manufacturing plant with 10,000 employees, with no prior knowledge or preparation; termed “Level Zero.â€

2. To represent the “poorly understood†case, we will simulate the changes to the process after a knee-jerk response to the knowledge of a viral threat; termed “Level One.â€

3. To represent the “understood but not documented†case, we will simulate the changes to the process after a conference call with a viral expert, doctor, HSS serum plant manager, and an Emergency Care Room (ECR) supervisor; termed “Level Two.â€

4. To represent the “documented but not modeled†case, we will simulate the changes to the process after a suggested Centers for Disease Control (CDC) report is issued detailing the impending viral threat; termed “Level Three.â€

5. To represent the “modeled but not simulated†case, we will simulate the changes to the process after the examination of a static process diagram; termed “Level Four.â€

6. To represent the “modeled and can be simulated†case, we will simulate the changes to the process after we apply the TRIZ STC operator to a running simulation; termed “Level Five.â€

7. We will ignore the impacts of job commutes, air travel, etc., on the spreading of the virus.

8. We will assume it is reasonable and possible to restrict contact among the members of the aerospace manufacturing plant with a “partial quarantine†once a viral outbreak is recognized [11] .

9. We will concern ourselves solely with casualty count, and ignore the side effects of casualties and quarantining on the effectiveness of the aerospace manufacturing plant to perform its function.

10. We will assume the solutions we apply as we proceed from Level One through Level Five are cumulative, i.e., the process changes made at a given level of understanding include the process changes made in all prior levels.

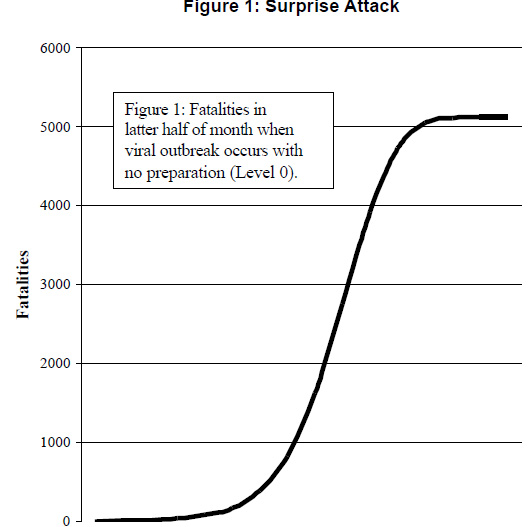

LEVEL ZERO: SURPRISE ATTACK

Without any prior warning or intelligence of any kind, an attack in the form of a deadly virus is unleashed on an aerospace manufacturing facility employing 10,000 individuals. After a month, the virus appears to have run its course. Below is a graph showing the fatalities over the latter portion of the one-month period:

As we see, the virus progressed very rapidly through the group, with a total casualty count of 51%. Surely, we could have done better than this had we a better understanding of the process, yes?

LEVEL ONE: MINIMAL UNDERSTANDING OF THE PROCESS

Intelligence tells us there is a very real and imminent viral threat. We know the virus is both deadly and highly contagious. Symptoms appear less than a week after an individual is infected, after which the person develops flu-like symptoms that persist for a period of a week or two, with what appears to be a 50/50 chance of survival [12] .

Our first response is to develop a serum, and at great expense, we do so. The serum is perishable, with a shelf life of only 7 days. Shelf life can be extended via a sophisticated controlled storage facility [13] , which keeps the serum at a very constant temperature. In this controlled storage, the serum lasts seven times longer, i.e., one week in controlled storage is equivalent to one day on the shelf. The controlled storage can hold 4000 units of serum. A specialized facility can manufacture 1000 units of serum a week. As a new batch of serum is added to the controlled storage, the 1000 oldest units are removed and destroyed.

The serum is only effective if administered after the first signs of symptoms, and therefore cannot be used as a vaccine for inoculation. The serum is also potentially dangerous if given to an uninfected individual with merely the flu [14] . To counteract this problem, we develop a test kit. Test results take 48 hours, and the test is only meaningful when administered after symptoms, or no more then 48 hours prior to symptoms. Within these parameters, the test is 100% accurate.

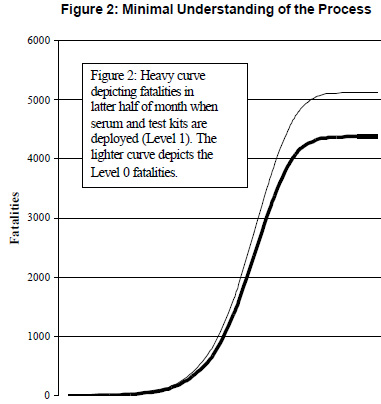

With 4000 units of serum in storage, the attack hits the aerospace manufacturing facility. Here is how the virus progresses over the latter half of a one-month period:

As we can see, the serum was effective at reducing the total casualty count from 51% to 44%. Our efforts were not as effective as we might have hoped, in part because we ran out of serum in the middle of the outbreak. This is an important point. Regardless of how innovative the technology used to develop the serum, without simulation, we would have a difficult time determining exactly how much serum to manufacture, keep in controlled storage, include in a shipment, and keep on hand at the hospital itself.

It is also very important to point out that in a real world situation, we would have no way of gauging the effectiveness of our efforts relative to the surprise attack. Clearly we need a better understanding of the process if we are going to come up with a cost effective, innovative solution to reduce the fatality count.

LEVEL TWO: IN THE MINDS OF EXPERTS

Let’s listen in on a conference call, lead by Consultant C from the CDC, with Doctor V, a leading virologist, Manager M, the HSS serum plant manager, and Nurse N, the hospital

ECR supervisor:

Consultant C: As you all are aware, I called this meeting because the CDC has identified a very real viral threat, termed the HSS virus, and we want to prepare ourselves for what intelligence is telling us could be an imminent attack. Let’s just go around the table and share what we know so we are all on the same page. We will start with you, Doctor V:

Doctor V: Thank you. The viral agent is highly infectious, but as far as we know, not airborne. We are fairly certain, though, that with direct physical contact, there is very high chance of infection, as high as 75%. There appears to be a one-day incubation period, followed by a 2-4 day infectious period during which the patient is contagious, but shows no symptoms. Flu-like symptoms then appear and last 7-14 days, with a 50% survival rate. The virus is basically a modified flu virus that rapidly mutates to circumvent the body’s natural defenses. We have been working with a development team to construct an effective serum. We are also happy to report that the development team has come up with a very effective test kit, so we can distinguish between this virus and the common flu. The serum itself is very delicate and not without its problems, though. I will leave the description of the serum to Manager M.

Manager M: Thank you, Doctor V. We can manufacture the serum at a rate of approximately 1000 units per week. The problem is not with the manufacturing process as I see it; the problem is with the storage of the serum. The serum is very sensitive to temperature fluctuations; even slight fluctuations start a chain reaction that results in rapid deterioration. We have special refrigeration equipment on site that can extend the effective life of the serum to seven weeks. By cycling inventory, we can keep 4000 units in storage at all times.

Nurse N: We have no room to install any temperature regulation equipment. I also doubt that we could handle any additional power requirements.

Manager M: Not a problem, Nurse N, we can ship to you overnight. The CDC requires we get the serum to you in 12 hours or less.

Nurse N: What will the shelf life of the serum be once we receive it?

Manager M: That depends on how long it has been in storage, normally it would last a week, but the serum loses a day of shelf life every week it has been in storage. Nurse N: My next question is, well, why don’t we just inoculate everyone? I don’t want to put a price on a human life.

Doctor V: Cost is not the issue. Due to a quirk in the HSS DNA, the serum is only effective if given after symptoms appear, and potentially very dangerous if given beforehand. That is why we developed the test kit. Nurse N: From what you are telling me, I am becoming concerned about patients panicking and coming in for multiple injections.

Doctor V: Precisely. Also, a rumor has started that multiple injections are more effective at halting the virus, which is patently not true. Funny how these rumors start.

Nurse N: (thinking) Manager M, could you please explain the test kit to me?

Manager M: We have developed a test kit that appears 100% accurate and returns a result in 48 hours. Unfortunately, the test is only valid after the first sign of symptoms, or no more than 48 hours prior to symptoms Consultant C: (thinking) Given everything that I have heard here, I suggest that we build another manufacturing and controlled storage facility to double the production and storage of the serum to 2000 units a week and 8000 units in storage, respectively, just to be safe; any other suggestions?

Nurse N: Not at this time, but doubling the amount of serum we have on hand sounds like a good precaution to me. I don’t want us to run out of serum during an epidemic.

Doctor V: I agree. Let’s double everything across the board.

Manager M: I agree.

Consultant C: Excellent. I will coordinate all of these efforts and put them into effect immediately.

After all of the above preparations have been made, the viral outbreak is unleashed against the aerospace manufacturing facility. Here are the results:

Well, that was certainly unexpected. We had as many fatalities after doubling the available serum as when we had no serum available at all. Why? Well, what happened was that by doubling the amount of serum we kept on hand, older serum was administered to the patients, and the weakened serum was less effective at combating the virus. Again, at this point in real life, not only would we not have discovered this blunder until it was too late; we would not even know that we increased our fatalities at the cost of doubling our expenses.

Once again, it is very important to note that in a real world situation, we would have no way of gauging the effectiveness of our efforts; we can not do a “trial run†of the spread of a deadly virus in real life. The value of simulation in improving a process that has consequences too catastrophic to warrant the construction of a real world test case cannot be overemphasized:

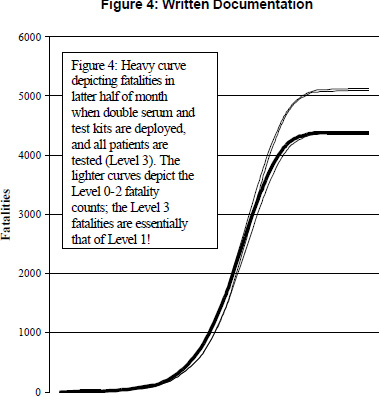

LEVEL THREE: WRITTEN DOCUMENTATION

Given the following report from the CDC, what should we do?

CDC Report: HSS Virus Alert Intelligence has informed us of a very real terrorist threat to this manufacturing facility from a viral agent termed HSS. Details of this virus, and the serum and test developed for it, follow. All medical personnel are hereby instructed to make themselves aware of this virus, its symptoms, and its testing and treatment procedures.

1. The HSS virus is not airborne. It is spread by direct physical contact, with a 75% chance of infection. We have estimated that a given employee makes contact with approximately 7 people per day. All of these factors, combined with the deadliness of this virus, make HSS a very real threat to this facility.

2. The incubation period of the virus is 24 hours, during which time the patient shows no symptoms and is not contagious.

3. After the incubation period, the infectious period of the virus lasts for a period of 2-4 days, during which time the patient is infectious but still shows no outward symptoms.

4. After the infectious period, flu-like symptoms last for a period of 7-14 days, with the patient having a 50% chance of recovery if left untreated.

5. A serum has been developed that is, at most, 95% effective at halting the progress of the virus. It can only be administered, however, after symptoms have appeared. A lab facility has been deployed that can manufacture 2000 units of the serum per week.

6. The serum is very perishable, with a shelf life of one week. A special controlled storage facility has been deployed that can store 8000 units. In this facility, the serum loses only one day of shelf life per week of storage. Regardless, as the serum ages, it becomes less effective at combating the virus.

7. A test kit has been developed for the virus. The test is 100% accurate, but only if administered no more than 48 hours prior to symptoms, or after symptoms have already appeared. Any patient reporting flu-like symptoms should immediately be administered the test.

8. All medical personnel should immediately report all positive test results to the CDC so that it may issue an alert if deemed appropriate. Giving every patient with flu-like symptoms an HSS test certainly seems like a good idea. Here are the results:

This is definitely an improvement, we are at least back to our previous Level One 44% fatality count, though once again keep in mind that in a real world situation, we would have no idea we had “done better than before.†Again, this point cannot be overemphasized.

LEVEL FOUR: MODELED BUT NOT SIMULATED

Let’s construct a static model of this process to see if we can detect any bottlenecks. Here is a portion of it:

Granted, we cannot (yet) simulate the model to analyze it, but by constructing the model, we certainly better understand the process of infection, testing, and treatment. In our efforts to better understand the process, we begin to realize there are key pieces of information we need to gather that we have not previously considered. In other words, the modeling of a process lends itself to a better understanding of the process, which in and of itself is of value.

We can only have a moderate degree of confidence in our model at this point, given we cannot perform a simulation to analyze it and see if it performs close to our real world Incubation Infectious Start Outbreak Contact a Person Infected? Back to Population No Done? Contact Already Infected Already Infected? No Yes Incubation Period Max? No No No More People to Infect. Yes Continue Go To Symptoms Yes Complete Infectious Phase Start Incubation Yes

Figure 5: Portion of static process model depicting the spread of the HSS virus. Contact a Person understanding. Regardless, from inspecting the model in its static form, we come to the conclusion that the high infection rate of the virus, depicted as “Contact a Person†in Figure 5, is a major factor.

While we can’t alter the infectious properties of the virus, we can limit the opportunities for infection. We apply TRIZ Principle 11, Cushion In Advance, “Compensate for the relatively low reliability of an object with emergency measures prepared in advance [15] ,†and have a conversation with the aerospace plant manager, who agrees to issue a “partial quarantining†order instructing all employees to minimize their personal contact once a CDC alert has been issued.

Here are the results after the outbreak with the partial quarantining in place:

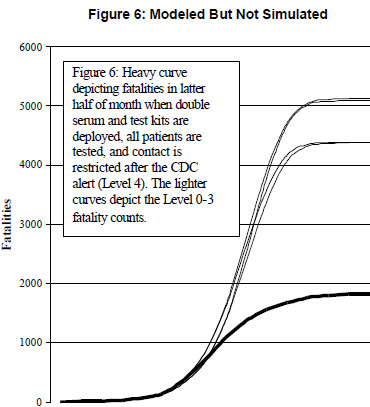

Now that we understand the process fairly well and have applied a TRIZ innovation principle to it, we have reduced the fatalities to 18%. But, what if we could actually simulate the model? Figure 6: Heavy curve depicting fatalities in latter half of month when double serum and test kits are deployed, all patients are tested, and contact is restricted after the CDC alert (Level 4). The lighter curves depict the Level 0-3 fatality counts.

LEVEL FIVE: MODELED AND SIMULATED

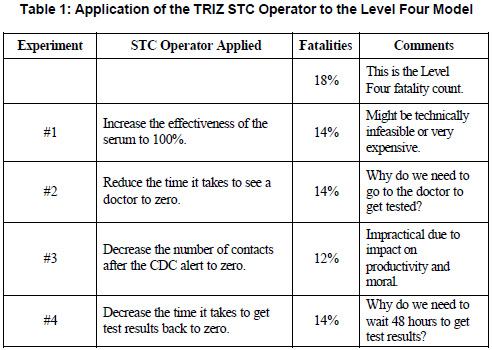

Now that we have a process model we can simulate, we can gather information and perform some experiments. Here is where process simulation and TRIZ demonstrate their symbiosis: simulation tells us where to innovate, and TRIZ tells us how to innovate. As an example of how simulation can assist us, what follows is a table of fatality counts generated by applying the TRIZ STC operator to various points in the simulation model:

Given the outcome of experiments #2 and #3 in the above table, how can we improve upon the speed of the diagnosis process? Well, the process is performed in two steps; first, the individual feels ill and makes a doctor’s appointment, which causes a delay. Secondly, the patient is given a test, and there is a delay in receiving the results.

Referring to experiment #2, we apply TRIZ Principle 3, Local Quality, “Each part of an object should be placed in conditions that are most favorable for its operation [16] ,†and decide to investigate the feasibility of developing a home test kit (HTK). Upon inspection, we discover the patient can easily perform the test, in that it is very similar in use to a home pregnancy test kit that returns results in 48 hours.

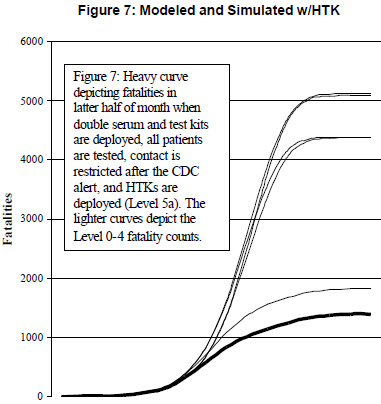

The HTK effectively reduces the process time it takes to “see a doctor and get tested†to zero! Here are the results:

The HTK reduces casualties down to 14%. But, referring back to experiment #4 in Table 1, there is more room for improvement if we can just get test results back sooner. In conferring with the serum plant technicians, they tell us that a 100% accurate test with more immediate results might be technically possible at great expense, but it would be a complicated process most definitely not suitable for home use. Another option that the technicians give us is an HTK that returns results faster, but is less than 100% accurate.

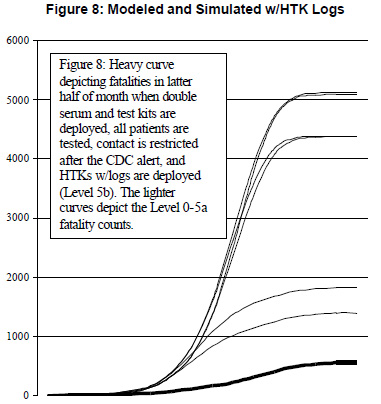

No problem. We instead apply TRIZ Principle 10, Prior Action, “Place objects in advance so they can go into action immediately from the most convenient location [17] ,†to the HTK as it stands. We instruct all of the employees at the aerospace manufacturing facility to perform a daily self-test, even if they don’t have symptoms, and to keep each kit at home for 48 hours prior to disposal. Now, if an individual wakes up with symptoms, they can inspect the results of the test performed 48 hours earlier, and immediately determine if they are infected with HSS. This reduces the effective time it takes to obtain test results at the first sign of symptoms to zero! Now, when an outbreak occurs, here is the outcome:

SUMMARY/CONCLUSIONS

1. Process modeling and simulation is symbiotic to the analysis phase of the TRIZ process, especially in analyses of systems with complex process interactions, in that it identifies where innovations are best applied.

2. Process modeling and simulation is invaluable in situations where the construction of a real world model is infeasible, due to restrictions involving cost, timing, and/or safety issues (TRIZ Principle 26, Copying).

3. Process modeling and simulation directly supports the application of the TRIZ STC operator.

ADDITIONAL INFORMATION

For additional information regarding this HSS process model, please go to

[http://www.igrafx.com/solutions/triz] .