Mutual Compensation of TRIZ and Axiomatic Design

Editor | On 20, Feb 2006

By: Kyeong Won, Lee and Young Joon, Ahn

Kyeong Won, Lee

Associate Professor at Korea Polytechnic University,

CTO at TRIZ Engineering & Consulting company “KID†in Korea

lkw@kpu.ac.kr

Young Joon, Ahn

Graduate Student at Korea Polytechnic University

ecodesign@paran.com

Abstract

TRIZ focuses on the one primary function and/or one harmful function in a system. However, big technical systems have to satisfy one more functions with the hierarchy between the many functions as system requirements. That is the one of main demerits of conventional TRIZ. To compensate it, the framework of Axiomatic Design for modeling multi functions is strongly recommended. In this paper the content and some case studies on combining TRIZ and Axiomatic Design, are reviewed and its effectiveness to solve a problem in the big system satisfying multi functions, is shown for TRIZ future.

1. Introduction

Inventive design is usually dependent on designer’s creativity. To design products creatively, many people developed methodologies that are useful for design. In mechanical design field, the design could be divided into two parts: conceptual design and detail design. In the conceptual design stage, designer defines functions and selects elements that implement functions. In addition, designer settles the arrangement and interference of components in this stage. On the other hand, in detail design, designer concludes the shapes and size of components on the basis of conceptual design. Sometimes, to evaluate performance, experiments or analysis researches are performed in this phase [1] . Usually, conceptual design is more significant than detail design because the cost and development time of product or process is much influenced by the former than the latter.

However, methodologies for conceptual design are less developed than those for detail design such as Taguchi method, Design of Experiments (DOE) and Optimization theory. In this thesis, Axiomatic Design and TRIZ will be reviewed because these methodologies are useful in conceptual design. Axiomatic Design is powerful in defining and analyzing system but has weakness in deriving ideas. On the other hand, TRIZ is mighty better in uiding concrete idea but system analyzing tool is relatively less powerful. Therefore, some papers about combining TRIZ and Axiomatic Design with case studies, were issued recently. In addition, in this article, TRIZ tools will be classified by Axiomatic Design matrix with each cases. This classification will be helpful to designer who is familiar with Axiomatic Design and wants to know how to upgrade the system.

2. Axiomatic Design In Axiomatic Design, the world of design is made up of four domains: the customer domain, the functional domain, the physical domain, and the process domain. Mostly, Axiomatic Design focuses on the functional domain and the physical domain. In functional domain, Functional Requirements (FRs) are defined on the basis of Customer Needs (CNs) that belong to customer domain. The Functional Requirements are minimum set of independent requirements that are the needs of the system to perform. Similarly, Design Parameters (DPs) are defined on the basis of Functional Requirements (FRs). Design Parameters are the key physical variables that satisfy the specified FRs [2] .

Axiomatic Design theory is composed of two main axioms and some theorems and corollaries. The first axiom is Independence Axiom. It means that independence of functional requirements must be always maintained. When there are two or more FRs, one of the FRs should not affect the other FRs. Therefore, designer has to choose proper DPs to satisfy the FRs independently (one to one mapping between one FR and the corresponding DP). Relation between FRs and DPs could be illustrated by matrix as follows. If more than one FRs and DPs exist in the system, design matrix can be divided by three types. Following examples show when three FRs and DPs are in the system – X means having relationship and O means non-relationship between FRs and DPs.

If the design matrix is diagonal (uncoupled design), each of the FRs can be satisfied independently by one DP. And if the design matrix is triangular (decoupled design), FRs can be satisfied independently by the DPs when DPs were set in a proper sequence. Thus, both the uncoupled design and the decoupled design satisfy the Independence Axiom. On the other hand, if design matrix is neither diagonal nor triangular (coupled design), usually, FRs cannot be satisfied by the DPs independently. Therefore, when the system was proved to be coupled, designer would better change the system to uncoupled or decoupled design.

Water faucet is one of the typical examples to illustrate the Independent Axiom. In former days, water faucet was composed of two valves, one is for controlling flow rate of hot water and the other is for controlling flow rate of cold water (Figure 1). If FRs of water faucet are proper quantity of water and proper temperature of water, DPs of former water faucet will be turned angle of two dials of the valves. This design is not good design in axiomatic design viewpoint, because DP1 and DP2 each influence both FR1 and FR2. Thus, this design does not satisfy the Independent Axiom.

However, nowadays, many faucets are changed to control water flow and temperature independently (Figure 2). If user lifts up the valve Y direction, water flow would be controlled, and if user turns the valve with Φ, water temperature will be controlled. Thus, this design is uncoupled design, because DP1 only affects FR1 and DP2 only affects FR2.

Although, Axiomatic Design itself does not guide designer how to change the system toward uncoupled or decoupled design, it is helpful, when designer wants to define a system or identify whether the system has problem or not. Especially if system is big and complex, it could be worthy to analyze the system with axiomatic design.

3. TRIZ

In TRIZ methodology, many tools for inventive thinking are involved, but contradiction and resolution concept is one of the most important tools. Altsuller and his colleagues distinguished three types of contradiction: administrative, technical, and physical contradiction [3] . The administrative contradiction concept is little used in TRIZ. When conflicts revealed in the system, it is called “technical contradiction†in TRIZ terms. That is, when designer introduce some useful function or reduce some harmful function in one subsystem, than another subsystem deteriorates simultaneously, this condition is called “technical contradictionâ€. On the other hand, if a parameter has to have property A to perform a necessary function, and at the same time, it should have property anti-A to execute a function, this circumstance is called “physical contradictionâ€. If designers want to solve

technical contradiction, they may use 40 Inventive Principles (with/ without Contradiction Matrix). And, if physical contradictions are in the system, they can use separation principles.

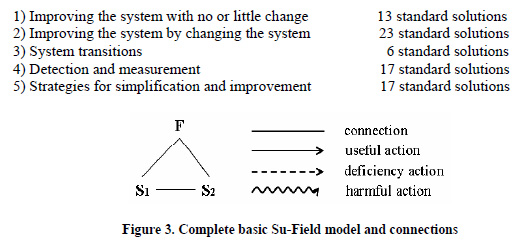

Su-Field model and 76 standard solutions is another significant tool in solving problem. In TRIZ viewpoint, system is or should be composed of an object or substance (S1), and another object or tool (S2) with some energy or fields (F). Referring lots of patents, Altsuller and his colleagues classified each model on the basis of interactions among two substances and field. In addition, in each case, they attached standard solution and examples. Su-Field modeling is useful when designer identifies the system and its resources. Designer can improve the system applying 76 standard solutions with identified system resources. Standard solutions are grouped into 5 large categories as follows [4] :

Besides, in TRIZ, some useful tools are available. Effects are scientific knowledge data lists that are useful to engineers for problem solving. Engineers can use the Effects conveniently and practically, because it is classified by functions. Usually, engineers are interested in not scientific Effect itself but its application. Thus, the Effects would supplement engineer’s knowledge. Nowadays, because many TRIZ softwares are developed well, engineers can search the exact function easily using the Effect database. Furthermore, because it is based on patent, TRIZ is applicable to predict future system. Altsuller suggested the Law of Technology Evolution as follows:

1) Stages of evolution

2) Evolution toward increased ideality

3) Non-uniform development of system elements

4) Evolution toward increased dynamism and controllability

5) Increased complexity then simplification

6) Evolution with matching and mismatching elements

7) Evolution toward micro-level and increased use of fields

8) Evolution toward decreased human involvement

Finally, ARIZ (Algorithm for Inventive Problem Solving) process is complex, but recommended to model and to find root cause of the difficult and complicated problems with systematic steps and solutions for ideal final results.

4. TRIZ for Axiomatic Design

4.1 Coupled / Decoupled matrix with physical contradiction (that is easily found in

the problem)

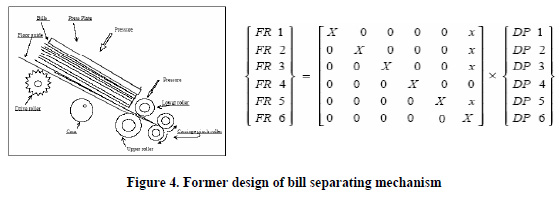

Kai Yang and Hongwei Zhang illustrated improving paper handling mechanism case study in their article [5] . To improve the bill separating mechanism, they analyzed the system and identified FRs and DPs. Then, they arranged the relationship between FRs and DPs with Axiomatic Design matrix (Figure 4) and the system found, was decoupled design.

â–ª FR1: give the a forward force to the first bill

â–ª FR2: give a backward force to the second bill

â–ª FR3: slant the cross section of the piled bills to make isolation easy

â–ª FR4: pull out the isolate bill

â–ª FR5: adjust the friction force

â–ª FR6: decrease the forward force after one bill is gone

â–ª DP1: upper rollers

â–ª DP2: lower roller

â–ª DP3: wedge-shaped floor guide

â–ª DP4: carriage pinch rollers

â–ª DP5: press plate

â–ª DP6: cam

Then, they found that physical contradiction is in the system; FR1 is the function for giving a forward force and FR6 is the function for decreasing the forward force. Thus, forward force should be existed and should not be existed. They solved this problem using separation principle, and made the system uncoupled.

Andrew Kankey and Madara Ogot published another article that contains system improving process using Axiomatic Design and TRIZ separation principles [6] . As the case study above, they analyzed the acoustics system and identified relationship between FRs and DPs. Then, they found the system was decoupled system and it contained some physical contradiction. After all, they improved the system using separation principles.

Therefore, these cases show that if design matrix indicates that the system is coupled or decoupled with physical contradictions are in the system, designers should use separation principle to improve the system.

4.2 Coupled / Decoupled matrix with technical contradiction (that is easily found in

the problem)

Zhang Ruihong et al. published case study of enhancing a paper machine with using both Axiomatic Design and TRIZ methodologies [7] . They used Axiomatic Design to analyze the system and identify problems of the system. Then, they found that the design of paper machine is decoupled.

Although paper machine was decoupled design, thus it satisfied Independent Axiom, customer wanted to improve the speed for machine productivity. However, if the paper machine speed is increased, each DPs that include former and dryer will be affected. Thus, two technical contradictions appear easily: 1. Designers hope to increase the productivity by increasing the speed, but the centrifugal force makes the pulp deviate from the wire. 2.

Designers want to increase the productivity by increasing the speed, but the dryer doesn’t meet the demand. To meet the demand, dryer should be large and complex system. Zhang Ruihong et al. solved these technical contradiction using TRIZ Contradiction matrix and Inventive principles. To enhance function of former, they applied number 10 and 28 Inventive principle. And to improve function of dryer, they applied number 10 and 34 Inventive principle.

Y. J. Kang et al. introduced another case study that includes system enhancing process applying Axiomatic Design and TRIZ Contradiction matrix [8] . As the case study above, they analyzed the polymer insulator system and identified relationship between FRs and DPs. Then, they found the system was decoupled system and it contained technical contradiction. After all, they improved the system using Inventive principle and Contradiction matrix. They improved tensile strength of polymer insulator by inserting loose body between fitting metal and FRP rod. This idea was found by number 1 and 35 Inventive principle.

Thus, these cases show that if design matrix indicates that the system is coupled or decoupled with technical contradictions are in the system, designers had better use the Inventive principles (with/ without the Contradiction matrix).

4.3 Coupled matrix with insufficient numbers of DPs

In Axiomatic Design, if number of DPs is equal to the number of FRs, system design is regarded as ideal design by theorem 4. Thus, when a design is coupled due to the greater number of FRs than DPs, designer should add new DPs so as to make the number of FRs and DPs equal to each other.

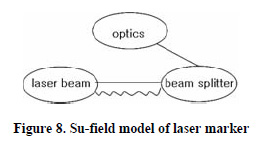

Gwang Seob Shin et al. published an article about beam splitter for laser marker that improved by applying Axiomatic Design and TRIZ methodologies [9] . Former laser marker layout and its Axiomatic Design matrix are shown in Figure 7.

DP1 (50% mirror) splits the laser beam equally and reflects 50% of the beam. DP2 reflects the beam that was divided by DP1. As shown in Figure 7, its design is coupled. To split the beam equally, angle of the DP1 should be adjusted. However, if user changes angle of the DP1 to divide the beam, direction of the right beam also is changed.

To settle this problem, Gwang Seob Shin et al. applied Su-Field analysis as Figure 8. Then,

they got an idea that was guided by 76 standard solutions. To eliminate harmful effect, the mirror (DP3) was brought in the system as Figure 9.

This example illustrates that when system design is coupled due to the greater number of FRs than DPs, designer can apply Su-Field model. If designer cannot make any idea in spite of applying Su-Field model, the Effect database could be helpful for producing ideas, too.

4.4 Technical Evolution

In Axiomatic Design, the best system design is uncoupled design, the next is decoupled design, and coupled design is the worst design. In this viewpoint, system will evolve from coupled design to uncoupled design. Water faucet example is the typical example. Therefore, although it is not as powerful as TRIZ, Axiomatic Design could be used a little for planning the next generation system.

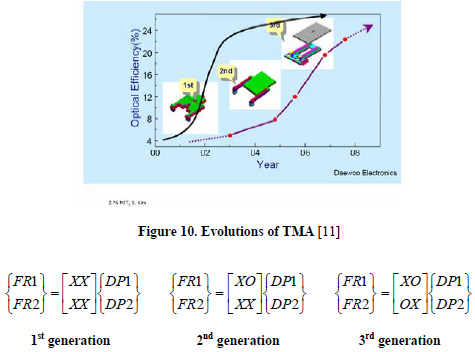

S. G. Kim and M. K. Koo illustrated evolution of Thin-film Micro Array (TMA) in the article [10] . In the first and second generation TMA designs, the actuator and the mirror were coplanar, fabricated at the same level over single sacrificial layer. In the first generation, the top layer functions both as the mirror and as the top electrode of the cantilever actuator. Thus, if actuator deforms with curvature, light scatters due to curved mirror surface (coupled). This phenomenon decreases contrast ratio seriously. In the second generation, mirror part was placed between the twin slim actuator. In this design, mirror is free from bending when the cantilever actuator deform with the same curvature (decoupled). In the third generation, design of TMA was developed to have the mirror on top of the actuator. The mirror fully covers the actuator with an air gap and the design equation became uncoupled.

â–ª FR1: light reflection

â–ª FR2: mirror tilting

â–ª DP1: cantilever top surface

â–ª DP2: cantilever sandwich

In TRIZ viewpoint, TMA evolution case has something in common with the Law of Technology Evolution. TMA evolved toward increased ideality, because it took more than 24 months to fabricate the TMA in first generation, 9 months in second generation, and less than 6 months in third generation. In addition, TMA has evolved toward increased dynamism and controllability since it had more degree of functional independency (controllability) through each generation.

This case shows that when designers plan to evolve the system, they have to develop the system toward uncoupled design. To redesign for next generation product, the Law of Technology Evolution and their evolution patterns will be useful because it guides products development directions. The effects database might be also helpful in that usually designers should change DPs to make system design uncoupled or decoupled.

5. Axiomatic Design for TRIZ

Most of TRIZ tools are focusing two functions or two objects. Technical contradiction and physical contradiction concepts mainly concentrate two functions or two properties. Su-Field modelling is usually for identifying interactions between two objects, though it could expand with other objects. Therefore, it is difficult to analyze complex systems having multi functions only with TRIZ. In this case, Axiomatic Design will be more useful for identifying the system structure, because it deals with multi-functions and multi-objects.

In addition, Axiomatic Design has another merit. It could be utilized when designer has to solve the administrative contradiction in TRIZ. It is called administrative contradiction, when engineer has to make some result, but does not know how to achieve the result. If system is decoupled design and engineers do not know the sequence of fixing DPs, engineers might think it is administrative contradiction, although it is not really administrative contradiction. Professor Suh named it as “imaginary complexity†[12] .

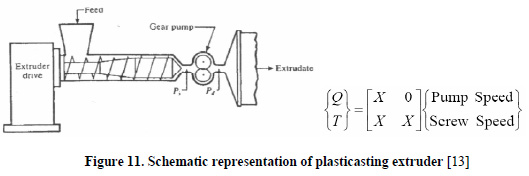

Figure 11 shows one plasticating extruder. Functional Requirements of the system are the pumping rate and the temperature of the extrudate. Pump speed affects only to pumping rate, that is, extrusion rate. And screw speed influences pumping rate and temperature. To meet all functional requirements, engineer should set the pump speed first, and then set the screw speed. If engineers set screw speed first, they suffer to satisfy functional requirements. When screw speed is fixed, and then pump speed is controlled, screw speed should be readjusted for the temperature of the extrudate. This system has simple structure, so engineer can relatively fix the design parameters easily. However, if system is complex engineer gets into difficulties to set up the system. In conclusion, if system is decoupled design and is very complex, but engineer doesn’t know the structure of the system, engineer might think it is administrative contradiction. However, engineers can solve the problem if they analyze the

system and identify sequences of fixing elements. Therefore, some administrative contradictions could be settled using Axiomatic Design.

6. Conclusion

As stated above, the Axiomatic Design is useful for identifying both structure of the system and problems of the system (specially, having multi-functions). However, this methodology does not provide specific tools for generating ideas. Thus, TRIZ tools such as Inventive principles and Standard solutions with some problem modelling process can complement the demerit of generating ideas for decoupling the design matrix in Axiomatic Design.

If the system is coupled or decoupled and has same FRs and DPs, designer would rather check contradictions than just try to generate ideas by intuition or experience of designers. Or if the system is coupled because of the greater number of FRs than DPs, designer ought to apply the Su-Field modeling or search the effect database. Sometimes, the Law of technology evolution would be useful in predicting the next systems objectively.

On the other hand, if engineers should analyze complex system, or are confronted with administrative contradiction, using Axiomatic Design would be one of the best choices. Therefore, for big or complex systems that have multi-functions, the relationship modeling between FRs and DPs using the Axiomatic Design with the design matrix, is strongly recommended as shown in Figure 12 with TRIZ. To decouple the design matrix or resolve the contradictions for improving the performance of system, the TRIZ tools are strongly recommended, too. For the new and innovative concepts using TRIZ and Axiomatic

Design, the other many useful engineering methods in detail design and analysis stages are applied to develop the concrete products sequentially.

References

1. Gyung Jin Park, Byung Soo Kang, “Analytical Methods for Design Practice†(officially unpublished)

2. N. P. Suh, 2001, “Axiomatic Design: Advances and Applicationsâ€, Oxford University Press.

3. Semyon D. Savransky, 2000, “Engineering of Creativityâ€, CRC Press.

4. John Terninko, Ellen Domb, Joe Miller, “The Seventy-six Standard Solutions, with Examples Section Oneâ€, TRIZ-Journal, February, 2000.

5. Kai Yang, Hongwei Zhang, “A Comparison of TRIZ and Axiomatic Design,†First International Conference on Axiomatic Design, 2000.

6. Andrew Kankey, Madara Ogot, “Improving the Acoustics in a Historic Building Using Axiomatic Design and TRIZâ€, TRIZ-Journal, June, 2005.

7. Zhang Ruihong, Tan Runhua, Cao Guozhong, “Case study in AD and TRIZ: A paper machineâ€, TRIZ-Journal, March, 2004.

8. Y. J. Kang, Alexander Skuratovich, P. K. Chung “TRIZ applied to Axiomatic Design and case study : improving tensile strength of polymer insulator,†ETRIA TRIZ Future Conference, 2004.

9. Gwang Seob Shin, Gyung Jin Park., “Conceptual design of a beam splitter for the laser marker using Axiomatic Design and TRIZâ€, Journal of the Korean Society of Precision Engineering, Vol.21, No. 5, May, 2004.

10. S. G. Kim, M. K. Koo, “Design of a Microactuator Array Against the Coupled Nature of Microelectromechanical Systems (MEMS) Processâ€, Annals of the CIRP, Vo. 49, No. 1, 2000

11. Lecture note in MIT mechanical engineering department, Multi-Scale System Design, Fall 2004

http://ocw.mit.edu/NR/rdonlyres/Mechanical-Engineering/2-76Fall-2004/8BEC776A-91A3-47EF-B752-2F3ADDED4539/0/lecture_2.pdf

12. N. P. Suh, 2005, “Complexity: Theory And Applicationsâ€, Oxford University Press.

13. N. P. Suh, 1990, “The Principles of Designâ€, Oxford University Press.

14. Kai Yang, Basem El-Haik, 2003, “Design for Six Sigmaâ€, McGraw-Hill.