Functional thinking in production process environment

Editor | On 10, Jun 2003

By: Ives De Saeger

P41 Industrial Services

Varendrieskouter 133, 9031 Drongen Belgium

ids@p41.be

1 Topics to cover

1.1 abstract

Using only functional thinking, one of the tools within TRIZ (the theory of inventive problem solving) the workplace can be redesigned and trimmed to a greater extent than with traditional process analysis using time & methods study together with lay out analysis. Functional thinking is described as a way to practice innovation and lead to new insights than what is known in process analysis, added value and method study. Functional thinking can easily integrate risk analysis and environmental issues thus expanding the use to greater needs. Using an academic simplified example of a subassembly functional thinking shows what results can be expected.

1.2 TRIZ: Try Reading It in Swahili

TRIZ, the theory of inventive problem solving, has nothing to do with a theory and is more about problem formulating than solving! TRIZ originated in Russia in 1946 through the work of Altshuller. Altshuller was a patent officer at the Russian Navy in charge of educating his fellow officers how to invent. Because of the lack of theories concerning inventing Altshuller developed one himself resulting today in a systematic way to innovate. Based on patent analysis several tools were created such as contradiction table, functional analysis, pattern of evolution, ARIZ (a step-by-step problem analysis), ideality and resources. TRIZ contains a database on physical, chemical and geometric effects gathered from science. TRIZ basic fundamental is “why invent the wheel if it already exists ?”. TRIZ helps to formulate your problem in a specific and systematic way but even provides you with solution directions how to proceed further.

1.3 The portal to process innovation: functional thinking

TRIZ offers an interesting look at functional thinking. Functional thinking is defining the functional relations between all the objects of the system considered. In a traditional assembly work station the following objects might appear: worktable, rack, storage bin, power tool, operator, half products, crates, hose pressured air, electricity cables, hoisting material, wheels of crate, litter, documents eg standard operating procedures, terminals etc.

We are not defining the functionality of the end product, and its components as it is normally done in TRIZ, but all the functions of the objects on the workplace and their relations to each other and to the half products. The functions can express useful and non-useful functions (here defined as opposites).

Useful – harmful

Insufficient-excessive

Missing- effective

A crate may deliver the function of protection (useful function) , contain a number of products and the ability to stack more products in height during transport (effective function). This crate may also damage the product (harmful function) , limit the operator from grasping the product out of the crate (insufficient function) and create extra frequented work ( eg work that has to be done, but not in every product cycle) eg the elimination of the foams, plastics and rubbers used to protect the parts. The feedback loop of waste material causes the need of more space on the work floor. (harmful functions).

An oven may be used to pre-heat objects but you would want to have less of this function, expressing an excessive function. Or the oven might perform the heating insufficiently by not heating the pieces quick enough and thus creating waiting time. The focus of process innovation is detecting the functional relations and using this functional analysis to

·Trim (eliminating unnecessary objects or functions, one of the basic approaches in process analysis)

·Combine functions

·Invert functions (the other way around)

·Improve process time

·Improve layout

·Determine contradictions

·Visualize sequences

·Deploy excessive, missing and harmful actions (safety)

·Improve process tool design

·Define attributes

·Start a creative process

·Define the ideal system

1.4 Functional Analysis Tree, an example

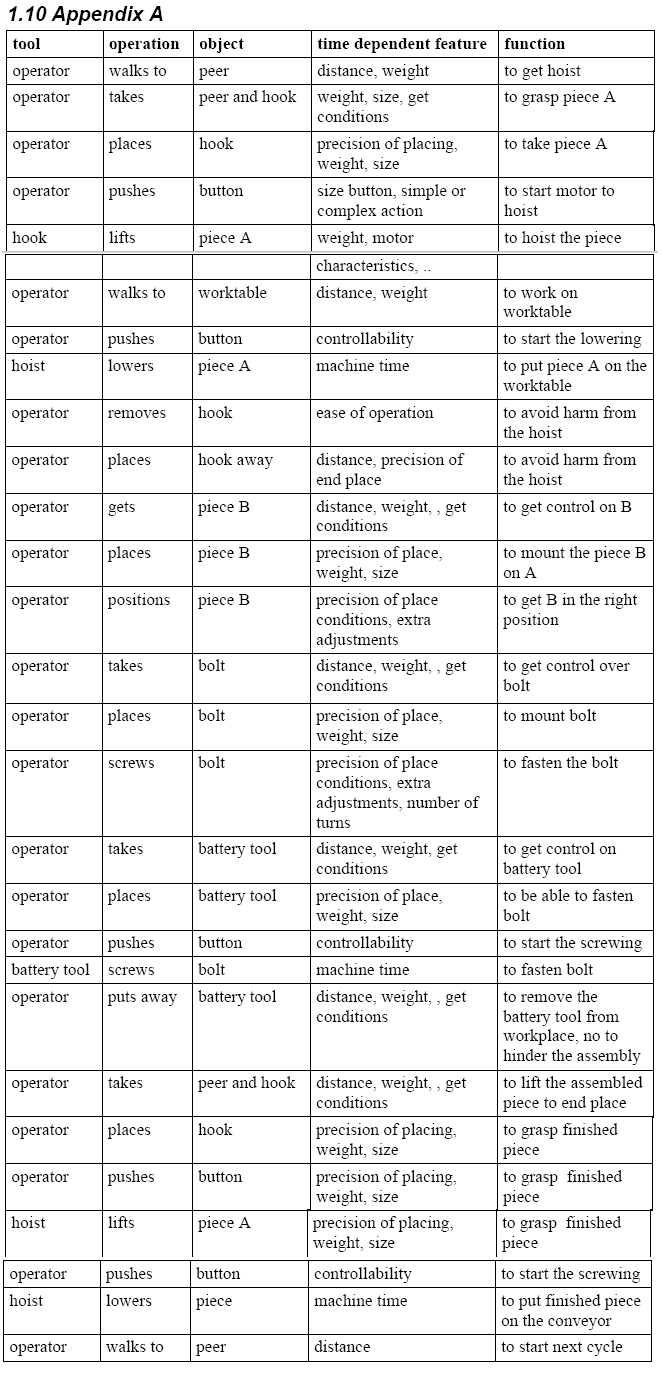

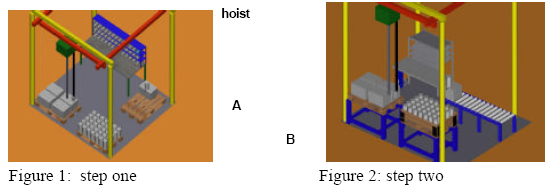

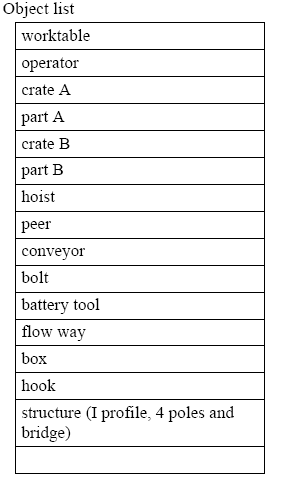

•The functional analysis will be applied to the following case (figure 2). A large part (A) situated on the left of fig 2, is lifted by use from a hoist to the worktable where the part is placed. The operator takes a piece (B, the cylindrical object) and positions it onto the large piece A, a bolt is screwed onto the piece (B) and the operator uses a battery tool to fasten it. The battery tools is not visible in the picture. The assembly is hoisted back to a roller. This assembly could be seen as a subassembly in a super system. The crates are placed by another operator and the assembled pieces are mounted in a larger assembly perhaps on a production line. The basic parts A, B and bolts are brought by logistics by means of fork truck.

•Figure 1 is added to show a previous step before a process analysis. some firms still use the step 1 lay out. The ergonomics are improved so the operator doesn’t have to bend to attach the hook to the large piece or bend to grasp piece B. A flow way, a rack with a FIFO system, is used in figure 2 to implement a x-bin system. The conveyor improves the distance the next operator has to take before he can assemble. The conveyor transports the assembled piece to where the next needs it.

This case is purely academic, normally the number of the added pieces will be higher and will be calculated from the cycle time.

A process analysis can be found in appendix A. (table 2, the time is not included since it is not an issue here.)

1.5 Using functionality in processes

1.5.1 Function finding

To identify the function of an object the question is “What it does and/or must do rather than what it isâ€. A “noun verb noun” is used to identify the function. From a process analysis viewpoint the “noun verb noun” is widely used . Using synthetic time standards verbs such as grasp, place, release, position, walk are common in use (look at process analysis map, appendix A). The operator uses the wrench. The verb is the action or operation. In this case ‘uses’ is the verb. “Uses” is too general to be the ‘functional’ description. The difficulty is defining the function so it will help define the system leading to improvements, innovation opportunities. The operator “holds†the wrench is a better description of the function. So it is clear that the verb is too important. The nouns used in a process analysis are the operations, a functional analysis however will reveal other nouns such as ‘holds’. The use of the worktable (= holds a piece and provides place to work) is hardly considered by a process analyst. The worktable will not influence the time and is therefore overlooked. However in an extreme elimination step it should also be considered. This is the advantage of using functional analysis, it will help you look at a process in a new manner. It will even include potential harmful functions which are normally deduced after improving a situation. Here it is possible to identify all functional relations (including the process operations as other relations performed by other objects within the system.) Looking at the process analysis table (appendix a) is it easy to make a functional process map. Define all the objects and link them functionally. A different representation of the ideation methodology will also be shown.

1.5.2 Applying functional thinking to the example

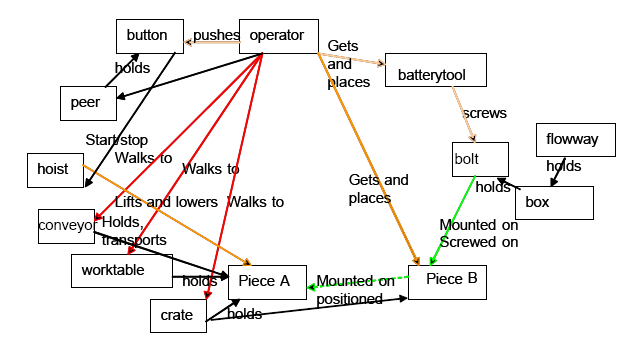

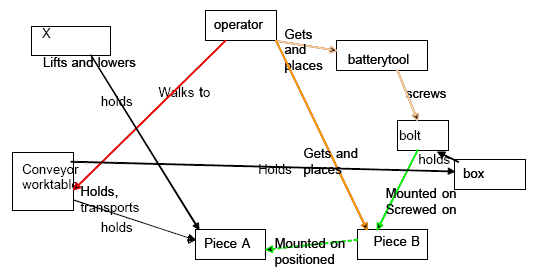

The functional analysis according to TRIZ (…) model is shown in figure 3. To focus on trimming most of the functions are considered effective. A lot of functions however could be added such as latent functions. A latent function is a function which is present but only appears statistically. An example is that the battery tool hurts the operator ( in fact is is the rotation of screw head which could hurt the operator), there is a certain percentage chance that this will happen. Another latent function is that the hoist doesn’t provide its function, hoisting, because of a malfunction of the hoist. Something is wrong and it needs to be fixed by maintenance.

Not all the objects from the object list table ??? will be added in the analysis. The structure to hold the hoist could be added but delivers the only function of holding but is not of interest at this moment.

The red arrow indicates non-added value, the green arrow indicates added value and the orange is in between. Black arrows are normally not considered in process analysis.

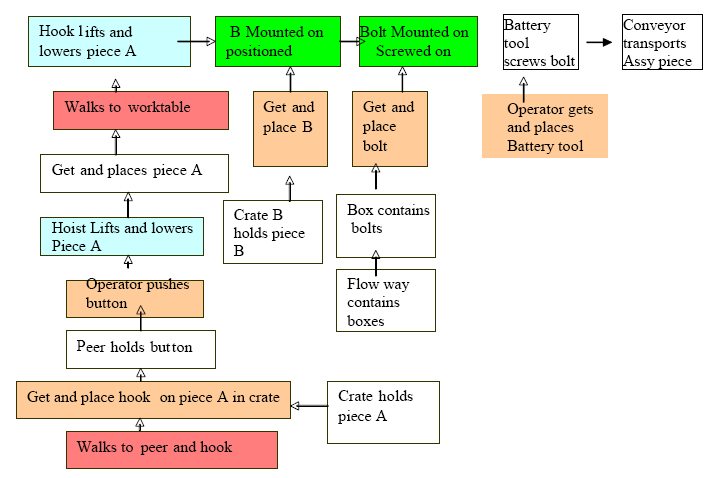

Trying to include the relationships between the functions and the time element a representation looking like a problem formulator model could be used.

A time relation between the functions reveals more clearly that the hoisting material is used to transport the main piece and needs to be done in order to assemble the pieces. The actual process of mounting the piece B and screwing the bolt are the added value functions of this whole representation of the process. Here you can move the operations to change the method of assembly.

Remarks in favour of map

These representations give us a model to get insight in the system, understand the relations between each component, leads to a better understanding of the added-value steps and the model can be used to combine functions, eliminate functions or reverse functions.

Remarks against map

The models also unable the process analyst is to see which function comes first. If you take all the objects viewed in a period of time, even though they might interact as a discrete function, the whole map is nothing more than a compression of all the initial states as if they would all exist at the same moment. This is why at first glance this map is not interesting from a viewpoint of processes. One conclusion could be that this compression might exclude ‘time’ contradictions as this model doesn’t give us any insight in what comes first. The bolt could be placed first on the piece B and might improve the positioning of piece B on A.

Interesting to notice is that there is clearly a difference between the operations as seen in the table and the functions described. A process analyst will write that the operator puts a piece on the worktable, the obvious function of the worktable (to work on and hold the piece) is normally not an issue. It is clear that several operations are needed to perform a function.

There is still some work to be done in the field of revealing timedependecy of the functions. The endproduct is slowly transformed from a raw material to the final product by adding pieces in a certain sequence.

1.5.3 Added value

Another point to consider are the features of the object. It is because a object is too heavy (feature weight) what causes a difficulty of action. It are the features of the objects where the problem may lay. Features such as grip, length, size, weight, distance to get/place, ease of place are clearly better to define the problem of handling a wrench and can be used to determine the time. It is because an object is small and jumbled that it takes more time to take this object than if it would be free. In describing functions one is looking at the tools and objects that produce direct change to another object. This change may be getting and placing actions. These actions only change the position of the object. Other actions such as welding, screwing, cleaning change the objects visually. A process study is looking for addedvalue actions. The value added action can be understood as the moment a product is added to another thus increasing the value of the whole. One representation of added value is the red-green model. Red applies to actions that do not contribute value, green is the opposite. Table ??? gives insight in the operations and features of object. The features described here determine the actual time needed to perform this action. This model labels operations in adding value or not. There are four colors. The colors are explained in the table 1.

The features of green are the same as orange since the only difference between green and orange is the end-place and green has a fixed value depending on the product. The place conditions are determined by the product designer, yet the get conditions are determined by process designer and depend on the package, the number of intermediate places. Some packages are placed direct on the work floor and determine the productivity as well. Contradictions might emerge from this fact also. It is the packaging (eg. size) which limits the operator for getting parts easily. The blue factor is situated on a higher level of the system (the super system). Therefore the features depend on the level of organization (planning), the type of process or the tempo of the operator. Blue can be associated with logistic planning systems and ideal work organization.

1.5.4 Method study

The sequences in process analysis are important and few software’s help to chart the possibilities because the number of permutations are too big. Analyzing the sequences or ‘work methods’ as it is also called is worth the effort because it can help innovating the process. The functional analysis helps to overcome and visualize this problem. All the objects are equally present and the sequence can be reviewed instantly. However some work remains to be done in defining time contradiction within TRIZ. A time dependency is included in the Ideation terminology.

The bolt can be taken by means of battery tool (magnetic head) and thus the bolt is screwed on the piece B. The operator doesn’t need to take the bolt anymore so some time is gained.

1.6 Re-thinking the known work floor

Applying the rules as defined earlier to trim , combine, invert functions one is able to rethink the work floor as we know it today.

Following table contains an object list and some trimming solutions, just by looking at the functional map.

This example clearly shows that functional analysis leads to a lean management environment! Trimming leads to cleaner workplaces as described in 5S, but also eliminates waste of motion, of movement (muda or waste).

Using this technique one can describe the risks involved by each remaining object to improve further the workplace.

The functionality ‘holds’ is excessively present on the piece A. Piece A is held by the crate, the hook, and the worktable and the roller. The author invites the reader to come up with easier systems to assemble!

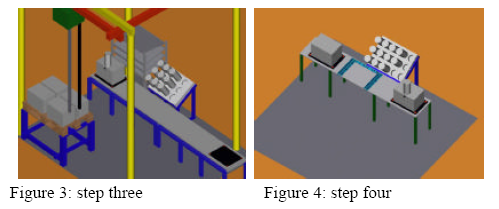

Figure 3 provides a improved worktable. The transportation of the main piece is done by a plate on wheels. Piece B is also more ergonomic designed. The ‘box’ has altered to a new foam like packaging. Piece a still has to be lifted to the worktable.

Functional analysis of step 4

Figure 4 eliminates the hoist completely, (so it was not necessary to include the structure to hold the hoist) its function is delivered by the fork truck or a new means of transportation. The kanban rack is included in the worktable. The table contains holes so the operator can take the necessary nuts and bolts.The space needed for the operations can be reduced 4 times.

The author invites the readers to come up with variants of this system to innovate production.

1.7 Conclusions drawn:

This paper investigates the use of functional thinking in a production process environment. This article hopes to stimulate process engineers to ask for better techniques to design the workplace and define processes. The current models used in TRIZ are usefull to apply on a process level but further development in this arera could result in revealing timecontradictions:)

Using functional thinking leads to lean manufacturing where safety, quality and maintenance go hand in hand. Each of them strenghting the functionalities of the objects. J

1.8 Author info:

Principle 41 Industrial Services aims to help SME’s in decreasing the process innovation gap by using TRIZ as a changemanagement tool. Ives De Saeger has got an degree in phsyiscs and is civil engineer has worked as consultant for Volks Wagen Brussels, Picanol, DAF trucks, Euromold a Nexans company to improve processes. Special thanks to Stephen Depijpere for the 3D drawing, Linda Van de Graaf, Danny Maes and Bart Neels for the discussions which strenghtend the article.

1.9 References

Boothroyd G., Dewhurst P. & Knight W., Product design for Manufacture and Assembly, Marcel dekker , 1994

Darell M., Hands-on Systematic Innovation, Creax Press, 2002

J.P. Baartman, Automation of assembly operations on parts, TU Delft, 2001

Kowalick J.F., TUTORIAL: USE OF FUNCTIONAL ANALYSIS AND PRUNING,

WITH TRIZ AND ARIZ, TO SOLVE “IMPOSSIBLE – TO – SOLVE” PROBLEMS, Triz Journal dec 1996

Miller J., Domb E., The Importance of Time Dependece in Functional Modeling, TRIZ Journal dec 2002

Rantanen K., Domb E., Simplified TRIZ, St Lucie Press,2002

ReVelle, J.B., Manufacturing Handbook of Best Practices, APICS, St Lucie Press, 2002

Terninko J., Zusman A. Zlotin B., Systematic Innovation, an introduction to TRIZ, St. Lucie Press, 1998

Vicente-Gomila, Applying some TRIZ concepts to the problem of harvesting and selection of potatoes, TRIZ-journal oct. 2001